User Manual

HOSE RECOMMENDATIONS

Oil Flow Hose Lengths Inside Diameter

USE

(

Min. Working Pressure

GPM LPM FEET METERS INCH MM PSI BAR

4-9 15-34 up to 10 up to 3 3/8 10 Both 2250 155

4-6 15-23 up to 25 up to 7.5 3/8 10 Both 2500 175

4-6 15-23 26-100 7.5-30 1/2 13 Both 2500 175

5-10.5 19-40 up to 50 up to 15 1/2 13 Both 2500 175

5-10.5 19-40 51-100 15-30 5/8 16 Both 2500 175

5-10.5 19-40 100-300 30-90

5/8 16 2500 175

3/4 19 Return 2500 175

10-13 38-49 up to 50 up to 15 5/8 16 Both 2500 175

10-13 38-49 51-100 15-30

5/8 16 2500 175

3/4 19 Return 2500 175

10-13 38-49 100-200 30-60

3/4 19 2500 175

1 25.4 Return 2500 175

13-16 49-60 up to 25 up to 8

5/8 16 2500 175

3/4 19 Return 2500 175

13-16 49-60 26-100 8-30

3/4 19 2500 175

1 25.4 Return 2500 175

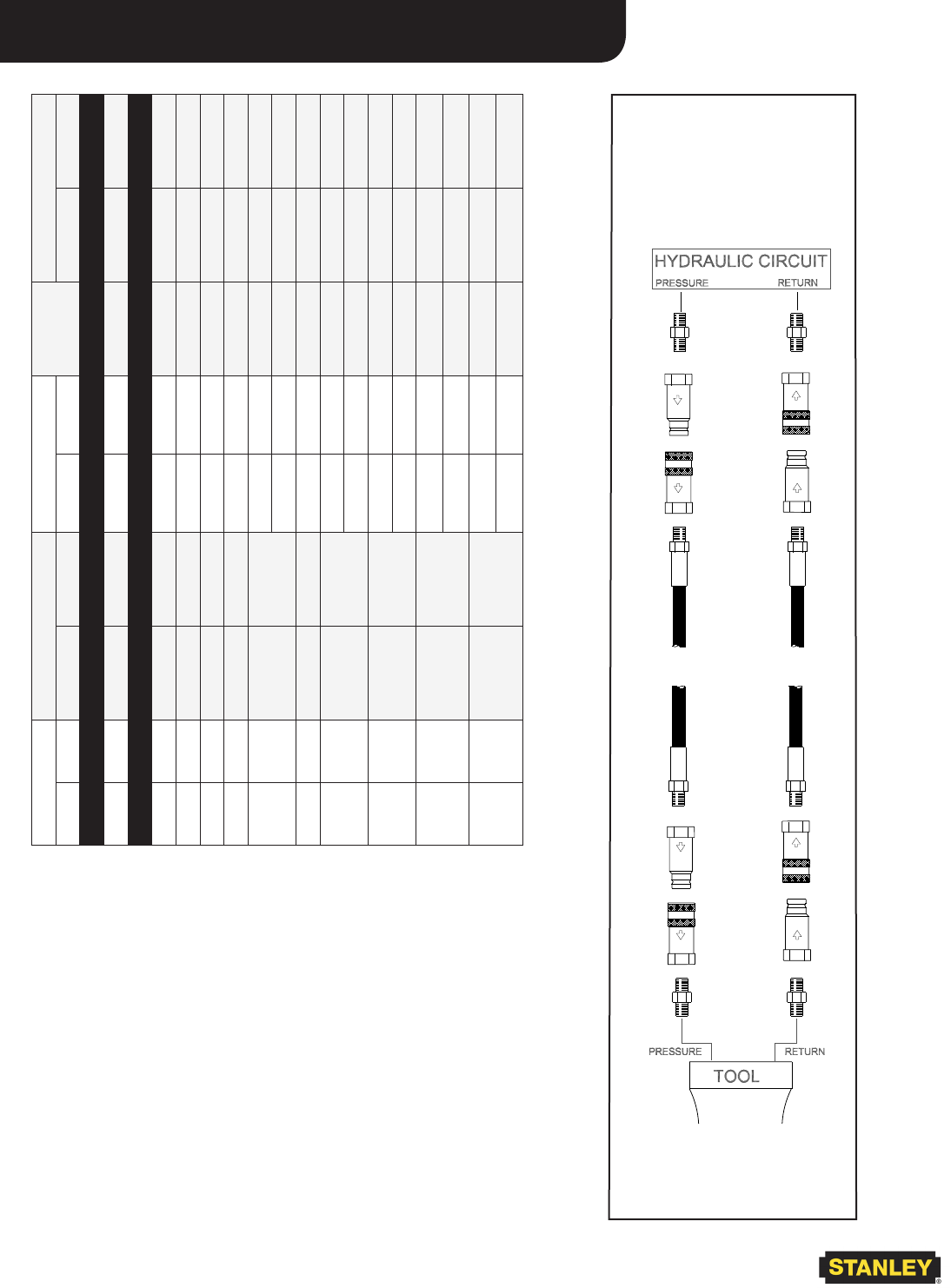

Figure 1. Typical Hose Connections

Recommendations

The chart to the right shows recommended

minimum hose diameters for various hose

lengths based on gallons per minute (gpm)/

liters per minute (lpm). These recommenda-

tions are intended to keep return line pressure

(back pressure) to a minimum acceptable lev-

el to ensure maximum tool performance.

This chart is intended to be used for hydraulic

tool applications only based on Stanley Hy-

draulic Tools tool operating requirements and

should not be used for any other applications.

All hydraulic hose must have at least a rated

minimum working pressure equal to the maxi-

mum hydraulic system relief valve setting.

PRESSURE

RETURN

<<< FLOW

FLOW >>>