Operating Hints

ENGLISH 14

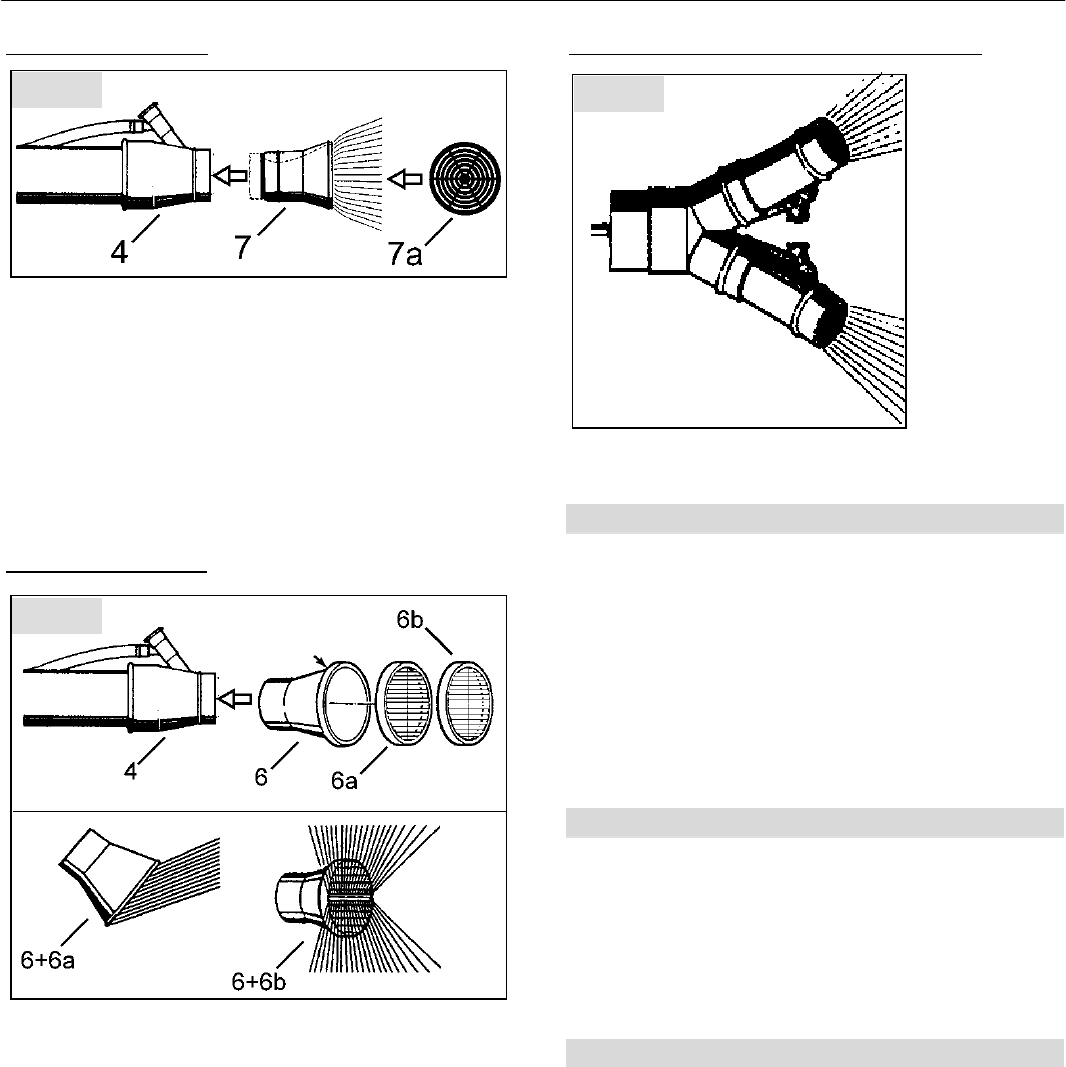

Wide-range nozzle (7):

When spraying plants and trees we recommend fixing

the wide-range nozzle (7) onto the red standard nozzle

(4). This ensures that a large area can be sprayed at

one time. Push the wide-range nozzle onto the

standard nozzle, until the bead engages.

In narrow spaces and for aftercare, we recommend

placing the wide-angle grille (7a) onto the wide-range

nozzle. This ensures that the spray velocity is reduced

and the spray is applied more widespread, to prevent

damage to leaves.

Nozzle attachment (6):

The nozzle attachment (6) is positioned onto the

standard nozzle (4) with the selected grille.

Use the dual grille (6a) when spraying cultures in rows

(e.g. vines, tomatoes, nurseries), to achieve a good

covering on the underside of the leaves.

The deflector grille can be replaced with a dual grille

(6b). The dual grille provides a 90° - 110° spray

pattern. The dual grille is usually used for spraying two

rows at a time. The deflector grille and the dual grille

can be placed onto the external diameter of the nozzle,

until the bead engages.

Dual nozzle (accessories, part no.: 49 00 137):

Remove standard nozzle (4) from the spray wand and

push the dual nozzle onto the spray wand.

7.4 Residual spray medium

Switch off the appliance as soon as no further liquid is

expelled, when the metering body is correctly

positioned for spraying, or air bubbles are visible inside

the lance supply hose.

The tank will then contain less than 100 ml residual

medium.

If you don’t want to refill the tank with spray medium

and you want to terminate spraying, dilute the residual

medium with 2 l of water. Dispose of this solution on

the treated area.

7.5 Strainer for accessory sets

When using the liquid pump (accessory part no.:

type 444 Î 44 00 114, type 450 Î 44 00 235) or the

ULV accessory (part no.: 49 00 479), a strainer is

integrated into the tank connector.

The strainer has a mesh size of 0.32 mm. Only use

original strainer part no.: 25 00 198 with standard mesh

size when replacing the strainer.

7.6 Checking the spray medium flow rate

At the beginning of the spraying season, check whether

the equipment flow rate (l/min) still corresponds to the

„Guide values“ table (see also item „Maintenance

schedule“).

For this, fill the equipment up to the maximum marker

with water, start using the equipment and spray for one

minute exactly at maximum operating pressure. Then

measure the water volume required to bring the water

level back up to the maximum marker.

The actual volume measured represents the flow rate

of the equipment in l/min at maximum operating

pressure.

It should not deviate by more than 10 % from those

listed in the „Guide values“ table. Should the actual

value be too low, sediments inside the metering body

may be the cause. Clean the corresponding parts and

repeat the checking procedure.

Fig. 9

Fig. 10

Fig. 11