21

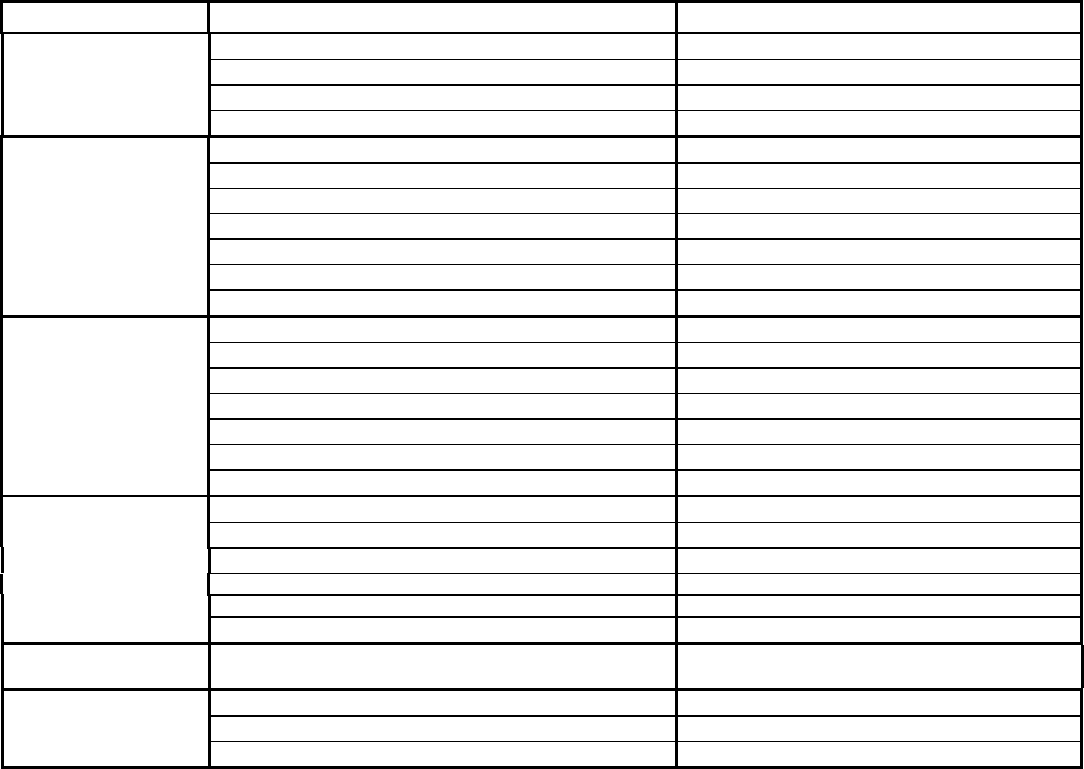

TROUBLESHOOTING

PROBLEM PROBABLE CAUSE CORRECTIVE ACTION

Starter Will Not Crank

1. Battery dead. 1. Service battery.

Engine

2. Blown fuse. 2. Replace fuse.

3. Electrical connections loose or corroded. 3. Clean and check connections for good contact.

4. Defective ignition switch.

4. Contact authorized SNAPPER dealer.

Engine Will Not Start

1. Blade engagement switch in the “ON” position. 1. Move blade engagement switch to “OFF”.

2. Park brake not set. 2. Set park brake.

3. Fuel tank empty. 3. Fill fuel tank with fresh fuel.

4. Engine needs choking. 4. Move choke control to “CHOKE” position.

5. Spark plug wire disconnected. 5. Place spark plug wire onto spark plug.

6. Battery weak or dead. 6. Service battery.

7. Faulty parking brake, blade or ignition switch.

7. Contact authorized SNAPPER dealer.

Engine Stalls After

1. Operator not in seat. 1. Sit in operator’s seat.

Running

2. Choke control in the “CHOKE” position. 2. Move choke control to “OFF” position.

3. Fuel tank empty. 3. Fill with fuel to proper level.

4. Engine air pre-cleaner and or air cleaner dirty. 4. Clean free of all debris.

5. Spark plug defective or gap set improperly. 5. Service spark plug.

6. Fuel filter stopped up. 6. Replace fuel filter.

7. Water, debris or stale fuel in fuel system. 7. Drain and clean fuel system.

Engine Loses Power

1. Excessive load on engine. 1. Lessen load.

2. Engine air pre-cleaner or air cleaner dirty 2. Clean or replace filters.

3. Engine oil level low. 3. Fill with engine oil to proper level.

4. Engine cooling fins & air intake screen excessively dirty. 4. Clean cooling fins, air intake screen of all debris.

5. Spark plug faulty. 5. Service spark plug.

6. Water, debris or stale fuel in fuel system. 6. Drain and clean fuel system.

Engine Backfires When

Turned To “STOP”

1. Throttle control set too “FAST”. 1. Set throttle control to “SLOW” and allow engine to

idle. Then, turn key to “OFF”.

Excessive Vibration

1. Damaged or bent mower blades. 1. Service mower blade(s).

2. Loose blade components. 2. Service and tighten loose parts.

3. Loose or missing air lift (if equipped). 3. Replace air lifts. Tighten to proper torque.

(Trouble Shooting Continued on Next Page)