12

Section 3 - MAINTENANCE

WARNING

DO NOT attempt any adjustments, maintenance,

service or repairs with the engine running. Stop

engine. Stop blade. Engage parking brake. Remove

key. Remove spark plug wire from spark plug and

secure away from plug. Engine and components are

HOT. Avoid serious burns, allow all parts to cool

before working on machine. Fuel Filler Cap and Vent

must be closed securely to prevent fuel spillage.

3.3.2. MOWER COMPONENTS (Continued)

4. Cleaning Mower Deck

a. Make sure fuel cap is on tight. Turn fuel shut

off valve (If equipped) to the “CLOSED” position.

Start engine and allow it to run until engine runs

out of fuel. Close vent on fuel filler cap. See

Figure 2.3.

b. Remove key from ignition switch.

c. Remove spark plug wire(s) and secure away

from spark plug(s).

d. Carefully stand YARD CRUISER on rear

bumper.

e. Clean underside of mower deck, removing all

accumulation of grass clippings and debris.

f. Lower YARD CRUISER to ground. Clean top

of deck, removing all grass clippings and debris.

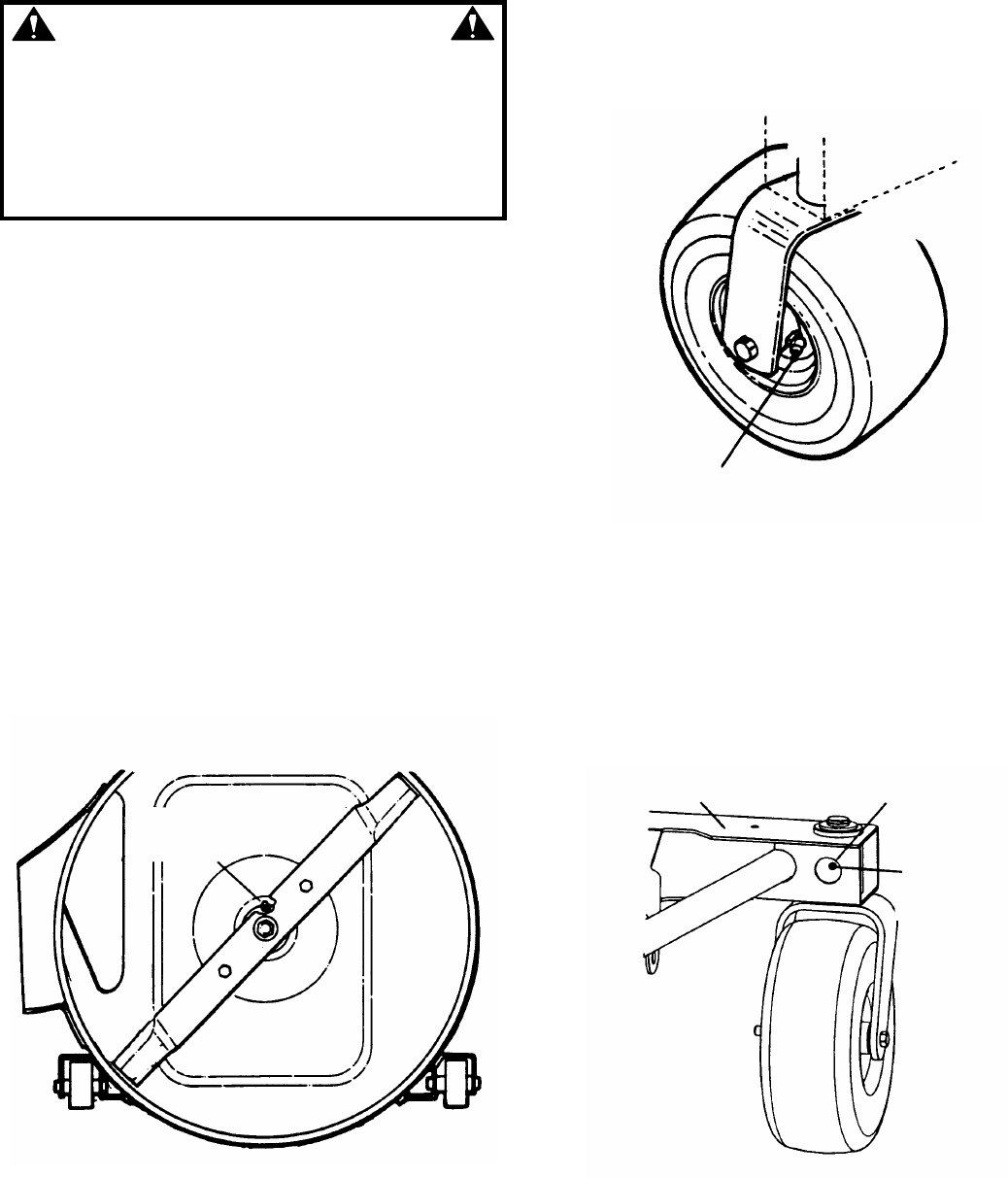

5. Mower Blade Spindle - Lubrication

a. Lubricate spindle bearings with three shots of

general purpose grease from grease gun. See

Figure 3.4.

FIGURE 3.4

6. Mower Deck Linkage - Lubrication

Lubricate all mower deck linkage pivot points with a

light coat of motor oil.

3.3.3. YARD CRUISER - LUBRICATION

1. Front Wheel Bearings

Lubricate front wheel bearings with five shots of

general purpose grease from grease gun. See

Figure 3.5.

FIGURE 3.5

2. Front Caster Wheel Pivot Shaft

The front frame cover will not have to be removed to

lubricate the pivot shaft. The access hole is at the rear

of the front structure underneath frame cover.

a. The pivot shaft grease fitting can be accessed

through a hole at the rear of the front structure.

Lubricate pivot shaft with three shots of general

purpose grease from grease gun. See Figure 3.6.

FIGURE 3.6

UNDERSIDE VIEW OF 33” DECK

LUBRICATE SPINDLE

BEARINGS

LUBRICATE

FRONT WHEEL

BEARINGS

FRONT STRUCTURE

ACCESS

HOLE

LUBRICATE

PIVOT

SHAFTS

FRONT COVER

REMOVED