9

Section 3 - ADJUSTMENTS & REPAIR

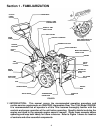

3.4 TILLER TINES

Your Snapper Tiller has right hand and left hand

tines. Replace both tines if blades become bent or

are badly worn or otherwise damaged. Use correct

Snapper replacement tines. The tines are secured

to the tine shaft with a shear bolt, Part No. 2-8725

and Lock Nut Part No. 9-0222 on each side. NOTE:

Two extra nuts and two bolts come with tiller. Keep

spares on hand in case a bolt shears off or

becomes lost while tilling. See Figure 11. DO NOT

over tighten these shear bolts as this will cause

premature failure. (Recommended torque is 5 to 8

foot pounds maximum). NOTE: Failure to use the

correct shear bolts could result in serious damage

to your Tiller. Use only the genuine Snapper

replacement bolts and lock nuts specified above.

These bolts are designed to shear at a specific

stress to prevent damage. DO NOT use substitutes!

FIGURE 11

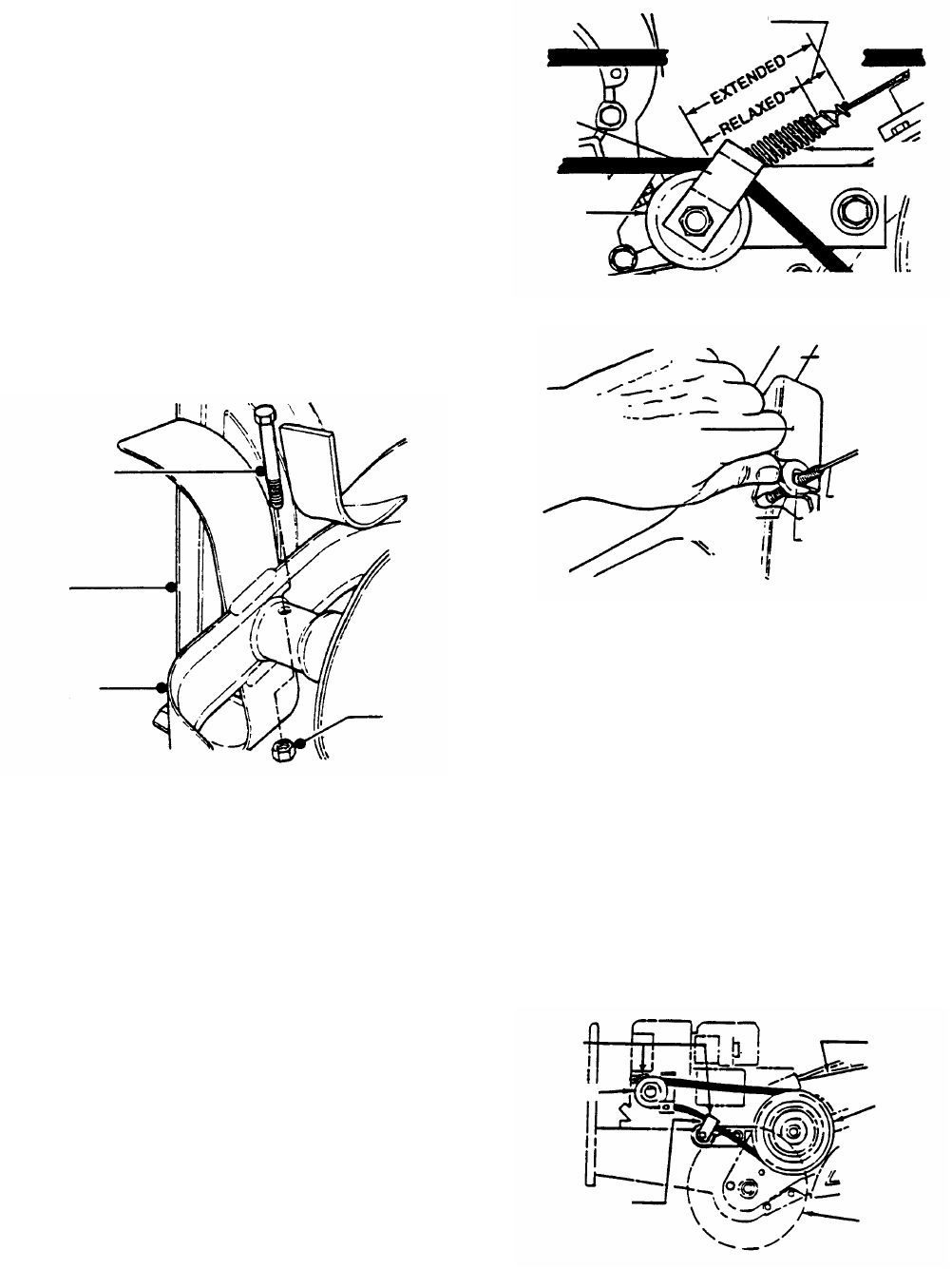

3.5 BELT ADJUSTMENT - REPLACEMENT

BELT TENSION ADJUSTMENT: Remove the cotter

pin that secures clevis pin to left wheel hub. Remove

clevis pin from left wheel hub and slide wheel out on

axle about 1”. Remove belt guard. Measure the

length idler pulley spring at the end of the control

cable in a relaxed position. Then move wheel and

tine control bail up to the handle bar and measure

the extended length of the spring. When properly

adjusted, the spring will extend 1/4” to 1/2”. See

Figure 12. To adjust, loosen and reposition the two

jam nuts on the threaded end of cable located on the

dash panel. Move jam nuts toward the end of

threaded end of cable for more tension. Move jam

nuts in a direction away from the end of threaded

end of cable for less tension. See Figure 13. After

adjustment, retighten both jam nuts against dash

panel. Reinstall belt guard. Slide wheel back into

operating position and reinstall clevis pin and secure

with hair pin.

FIGURE 12

FIGURE 13

3.5.1 TENSION TEST: Start the engine with tiller in

neutral. Shift transmission into FWD & TILL and pull the

wheel and tine control bail up against the handle bar.

Tines and wheels will start to rotate. Release control bail.

Tines and wheels should stop rotating immediately. If

rotation continues after release of control bail then clutch

spring tension is to great and will have to be readjusted

as described in BELT TENSION ADJUSTMENT Section.

3.5.2 BELT REPLACEMENT: Pull the clevis pin from

the left wheel and slide the wheel out 1”, remove belt

guard and then the old belt. NOTE: Replacement belt

must go over the top of the idler and be within the belt

guide as shown in Figure 14. Check belt tension as

described in BELT TENSION ADJUSTMENT Section.

Reinstall guard, push left wheel back into position and

secure with clevis pin and insert and secure cotter pin.

FIGURE 14

SHEAR BOLT

(TORQUE TO

8 FT. LBS.)

TINE

COVER

TINE

ASSEMBLY

LOCK

NUT

1/4” TO 1/2”

BELT

GUIDE

IDLER

PULLEY

IDLER

PULLEY

SPRING

HANDLEBAR

DASH PANEL

CLUTCH

CABLE

MOVE NUTS

TOWARD END

OF CABLE

FOR MORE

TENSION

LOOSEN

JAM NUTS

BELT

GUIDE

DRIVE

PULLEY

BELT OVER

TOP OF IDLER

SHIFT

LEVER

DRIVEN

PULLEY

REMOVE

LEFT HAND

WHEEL &

BELT

GUARD