21

Section 4 - ADJUSTMENTS & REPAIR

WARNING

DO NOT attempt any adjustments, maintenance, service

or repairs with the engine running. STOP engine. STOP

blade. Engage parking brake. Remove key. Remove spark

plug wire from spark plug and secure away from plug.

Engine and components are HOT. Avoid serious burns,

allow all parts to cool before working on machine. Fuel

Filler Cap and vent must be closed securely to prevent

fuel spillage. Once blade is disengaged it should come

to a stop in 3 seconds or less. If the blade continues to

rotate after 3 seconds the blade brake must be

adjusted. DO NOT continue to operate the machine if

the blade brake is not operating properly.

4.1 ENGINE ADJUSTMENTS & REPAIR

Refer to the engine owner’s manual for those

adjustments and/or repairs that can be made by the

owner.

4.2 MOWER DECK & COMPONENT ADJUSTMENTS

The following mower deck and component

adjustments and repairs can be made by the owner.

However, if there is difficulty in achieving these

adjustments and repairs, it is recommended that

these repairs be made by an authorized SNAPPER

dealer.

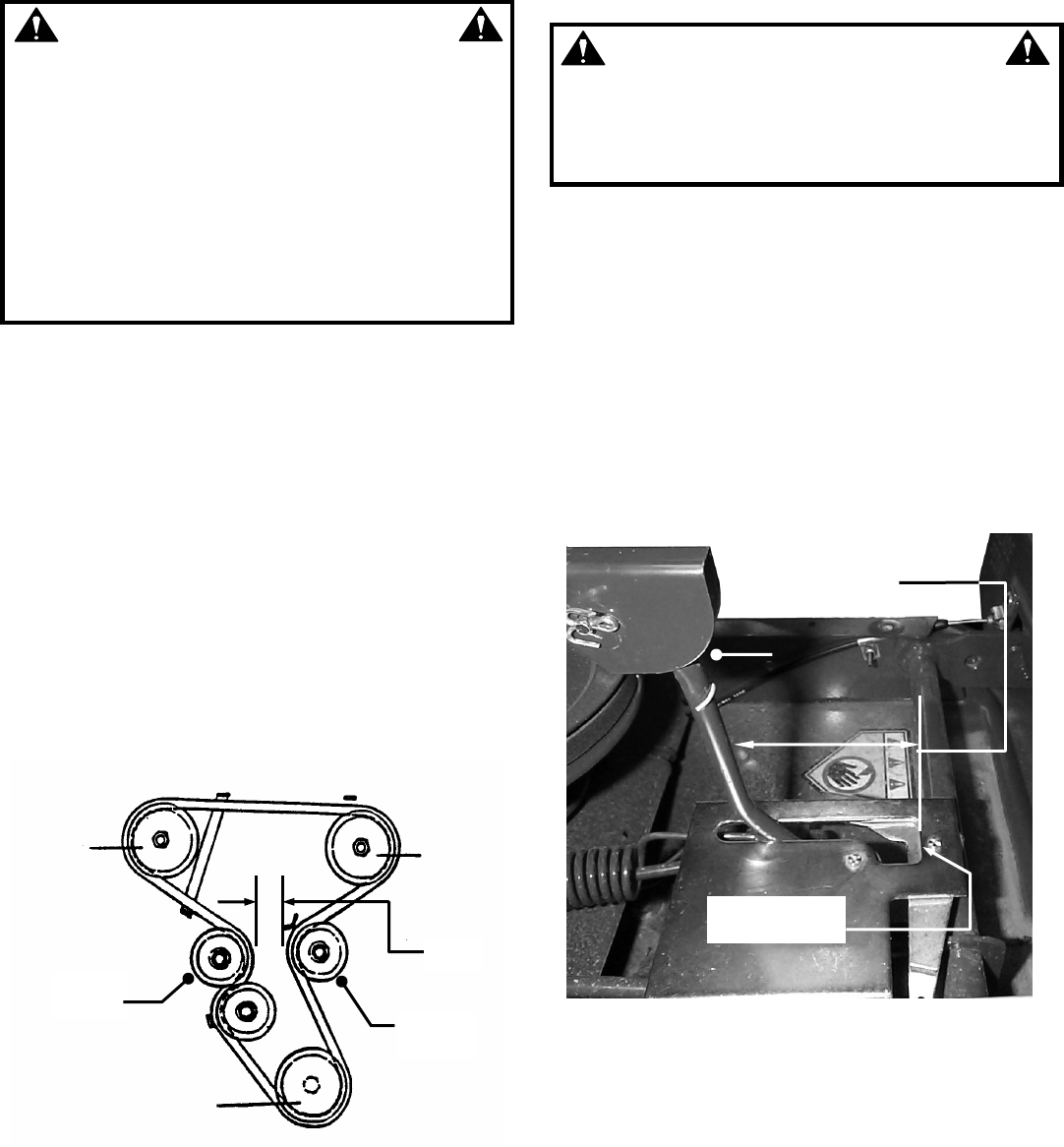

4.2.1. MOWER DRIVE BELT ADJUSTMENT

On 42” models, the mower drive belt DOES NOT

require adjustment. If the belt does not drive blade

properly, replace belt. See Figure 4.1 for belt

routing.

FIGURE 4.1

WARNING

DO NOT operate machine until blade brake is

adjusted and functioning properly. If blade stop time

cannot be achieved with the adjustment procedure

described above, take the machine immediately to

an authorized SNAPPER dealer.

4.2.2. BLADE BRAKE ADJUSTMENT

The automatic Blade Brake should stop the blades

within 3 seconds anytime the blades are

disengaged by moving blade lever to the "OFF"

position or by releasing the Blade Pedals. Check

this by disengaging the Blade Lever as shown in

Figure 4.2. Perform the following measurement

and adjustment.

1. With the blade engagement lever disengaged,

measure the distance between the front of the

blade lever and the edge of the latch plate. The

dimension should be 3” to 3-1/4" clearance

between lever and edge of plate. See Figure 4.2. If

the dimension is incorrect go to step 2.

FIGURE 4.2

(Continued on Next Page)

IMPORTANT: On 42” deck models do not require belt

tension adjustment. But, if front frame assembly clamp is

loosened for any reason, recheck belt spacing between

idler pulley and fixed pulley. Place deck height lever in the

3rd position. With blade lever in the “ON” position, the

distance between the idler pulley and the fixed pulley

should be 2-1/8”. See Figure 4.1.

RIGHT

SPINDLE

PULLEY

LEFT

SPINDLE

PULLEY

TOP VIEW OF BELT ROUTING

ENGINE DRIVE

PULLEY

ASSEMBLY

3” to 3-1/4”

CLEARANCE

MEASURE FROM

THIS EDGE

BLADE

LEVER

DISENGAGED

2-1/8”

IDLER

PULLEY

FIXED

PULLEY