16

Section 3 - MAINTENANCE

WARNING

DO NOT attempt any adjustments, maintenance or

service with the engine or blades running. Stop

blades. Stop engine. Engage parking brake. Remove

key. Remove spark plug wires from spark plugs and

(gas only) secure wires away from spark plugs.

Engine and components are HOT. Avoid serious

burns by allowing all parts sufficient time to cool.

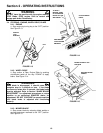

3.3.7. FRONT WHEEL BEARING - LUBRICATION

1. Lubricate front wheel bearings with five shots of

general purpose grease, from grease gun. See

Figure 3.6.

FIGURE 3.6

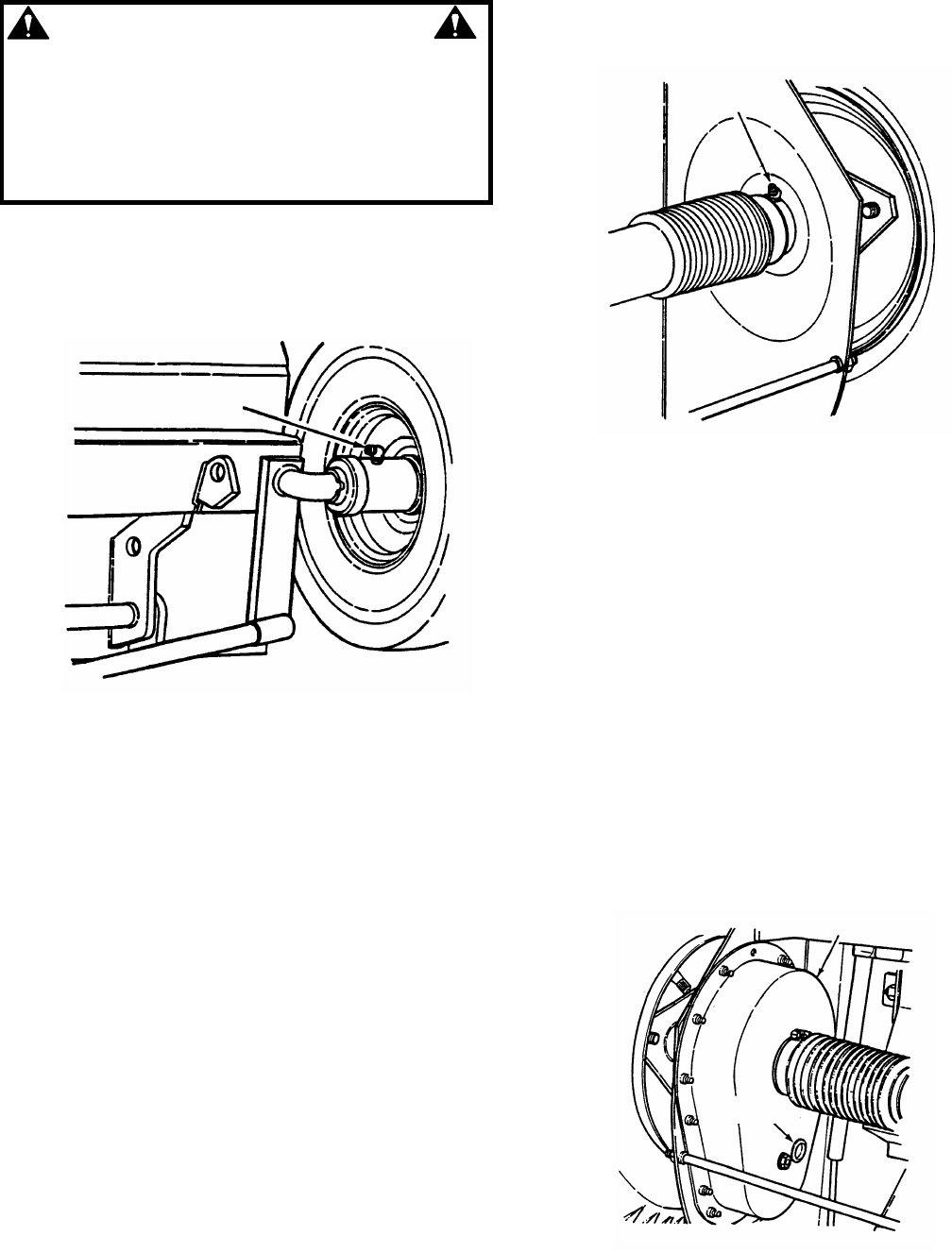

3.3.8. REAR AXLE BEARING - LUBRICATION

1. The left rear axle bearing on 28” and 30”

machines requires three shots of general purpose

grease from grease gun. See Figure 3.7.

NOTE: Some models are equipped with a pre-

lubricated sealed bearing and require no additional

lubrication.

2. The right rear axle bearing is lubricated by the

differential lubricant and requires no grease.

FIGURE 3.7

3.3.9. DIFFERENTIAL/CHAIN CASE - LUBRICATION

1. Stand rear engine rider on its rear bumper and

check the fill/level plug, for cracks and wear. Replace

fill/level plug if signs of wear are visible.

IMPORTANT: If the Rear Engine Rider will be on its

rear bumper for longer than two hours, remove the

battery. Refer to Section “BATTERY REMOVAL”.

2. To check lubricant, remove fill/level plug and

visually inspect for lubricant on the internal parts of the

differential. If no lubricant is visible on the internal

parts of the differential, add transmission grease as

needed. See Figure 3.8.

IMPORTANT: Overfilling of the differential with lubricant will

cause lubricant to leak onto drive components of the Rear

Engine Rider.

FIGURE 3.8

FRONT WHEEL

GREASE FITTING

LEFT REAR

AXLE BEARING

GREASE

FITTING

PLUG

DIFFERENTIAL