Adjustments

26

AUGER DRIVE ADJUSTMENT

1. Check that the auger cable (A, Figure 18) is on top of

cable button (B) as show in Figure 18.

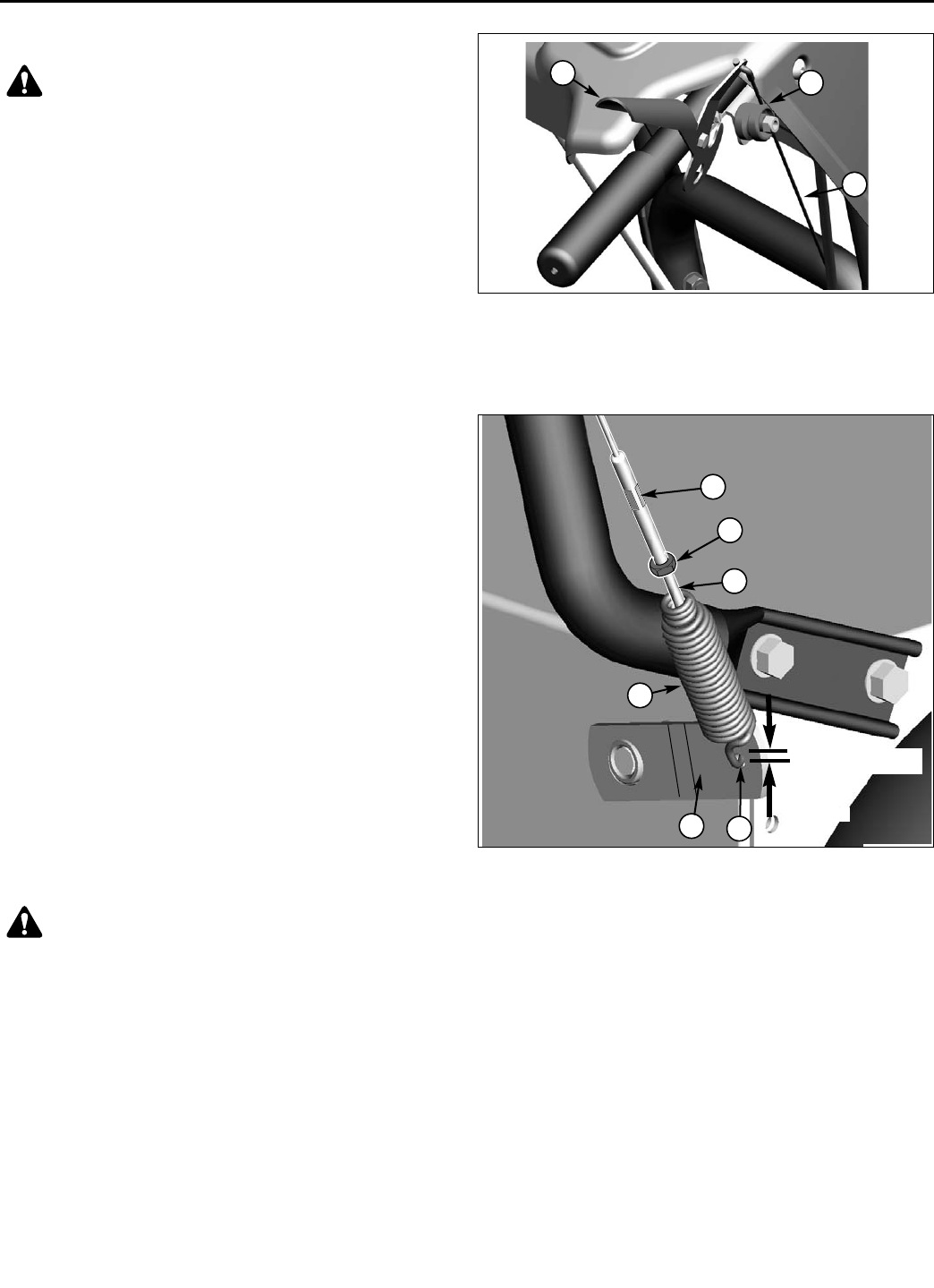

2. With the drive lever released, the hook (B, Figure 19)

should barely touch the lever (C) without raising it.

There can be a maximum 1/32” clearance as shown.

3. To adjust, loosen nut (D) by holding the adjusting

flats (A) and turning nut (D). Turn adjustment flats

and hold screw. The adjustment screw is a phillips

screw and the head can be held or turned by insert-

ing a screwdriver through the spring (F).

4. Hold adjusting flats (A) and tighten nut (D).

5. Start unit and check auger. Auger must not be

engaged unless auger control is depressed.

6. With engine running, fully depress auger control, the

auger should engage and run normally.

7. Release auger control. Auger must stop within 5

seconds.

8. If auger does not operate properly, stop engine and

recheck drive linkage adjustments.

9. If auger linkage is properly adjusted, auger drive belt

tension may require adjustment. See “Belt

Adjustment” in this section of the manual.

TRACTION DRIVE CABLE

ADJUSTMENT

Initial Adjustment

1. With the drive lever released there should be no

slack in cable when moved slightly from side to side.

Figure 19. Auger Drive Adjustment

A. Adjusting Flats D. Nut

B. Spring Hook E. Adjustment Screw

C. Lever F. Spring

WARNING

Do not over-tighten, as this may cause traction

drive to engage without depressing the traction

drive control (arm must remain in down position).

Verify that the cables are not over-tightened: With

speed selector in position 1 and traction drive

control fully released, push snowthrower forward.

The unit should move forward freely.

If unit does not move forward freely, the cable has

been over-tightened. To remedy, loosen tension

on clutch cable slightly, and recheck.

A

C

WARNING

Do not over-tighten, as this may lift the lever and

cause auger drive to be engaged without depress-

ing the Auger Control.

D

E

B

F

1/32” (.080cm)

Figure 18. Auger Cable Button

A. Auger Drive Cable

B. Auger Cable Button

C. Lever

A

C

B

2. To adjust tension on the cable slide the cable boot

(A, Figure 20) off the cable adjustment bracket (D).

3. Remove the “Z” hook (C) from the cable adjustment

bracket (D) to a different adjustment hole. The cable

should have no slack. The cable should have no ten-

sion or load.

NOTE: If the cable is too slack the unit will not drive. If

the cable is too tight the drive will be engaged without

pushing the handles down.