2.0 Operating Instructions

1. Connect discharge hose to machine outlet. (Fig. 2.2-1)

2. If optional low pressure downstream, in-line chemical injector is to be used (i.e. a Simpson SC 242 or

252 Series chemical injector) connect the injector at this time (Fig. 2.2-2). For instructions on connections

and use, see in-line chemical injector operating instructions

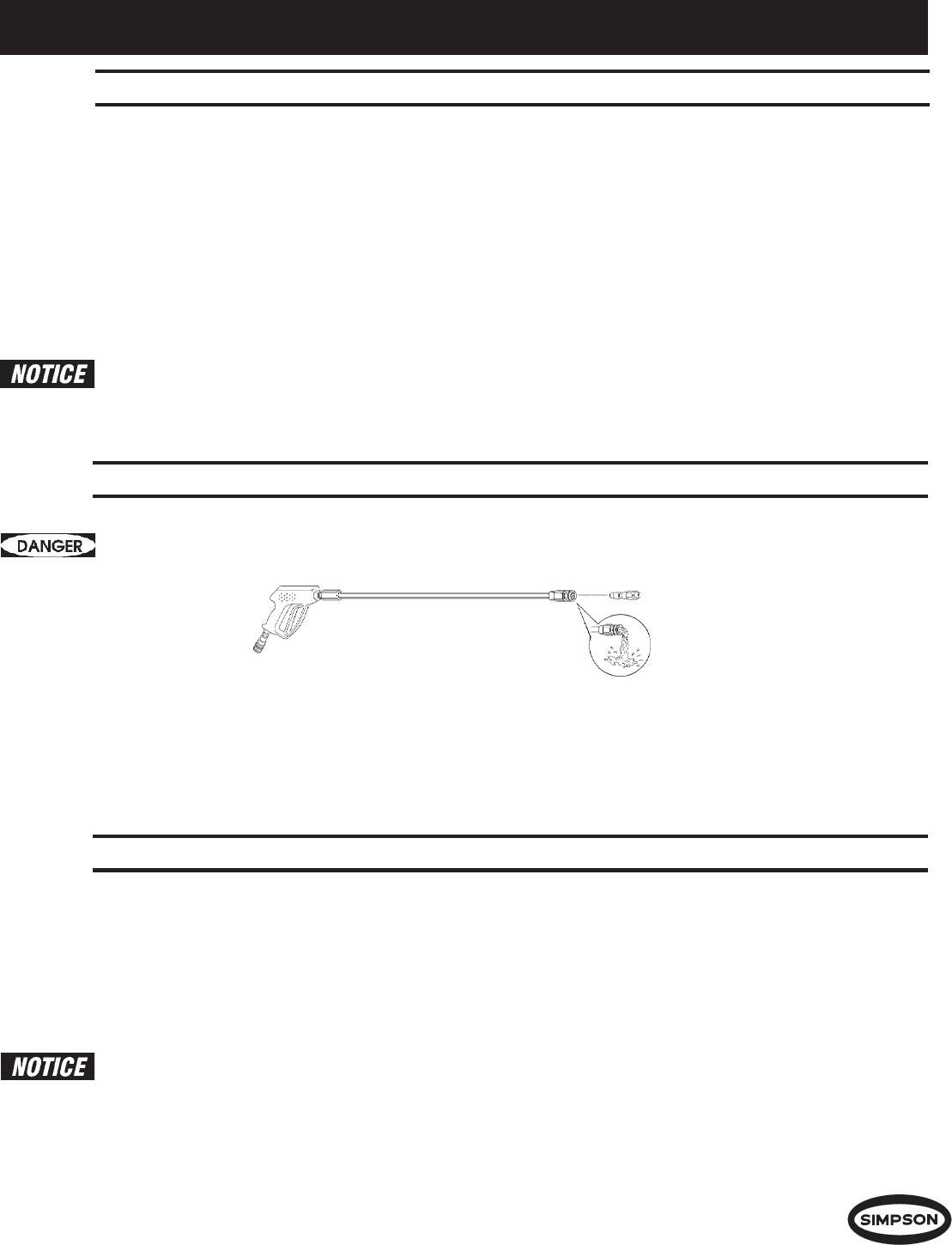

3. Connect gunvalve to discharge hose with quick coupler (Fig. 2.2-3). DO NOT INSTALL CLEANING

NOZZLE AT THIS TIME. Quick coupler sleeves must be pushed into locked position to prevent acciden-

tal uncoupling (Fig. 2.2-5).

4. Check inlet water filter for blockage then connect water supply hose to machine. Use a 3/4" I.D. or larger

hose with standard 3/4" garden hose fittings. (Fig. 2.2-4)

Incoming water supply must deliver gallons per minute greater than machine capacity.

If questionable, check supply at machine. If supply is insufficient, do not operate from this

outlet. For residental use, the outlet closest to the meter tap will usually deliver the highest

gallons per minute output. DO NOT connect to shallow wells used for lawn sprinkling. Connect

only to clean city water supply or deep domestic well.

2.3 Before Starting Machine

DO NOT OPERATE GASOLINE AND DIESEL ENGINES IN ENCLOSED AREAS! OPERATE

IN WELL VENTILATED AREAS ONLY!

FIGURE 2.3 - GUNVALVE, EXTENSION, & NOZZLE

1. Locate machine on a level plane.

2. Turn on water supply. There should be no nozzle in the extension at this point.

3. Pull gunvalve trigger, allowing air in system to escape.

4. When water flows in a full steady stream, release gunvalve trigger. (Fig. 2.3)

2.4 Starting Gasoline / Diesel Engine Machines

1. Check position of fuel valve, and if closed, open valve. For more detailed information on starting the

machine’s engine, see engine instruction manual.

2. Choke: Close choke on carburetor by moving lever in proper direction. If engine is warm or air tempera-

ture is high, close choke valve half-way, or keep it open fully.

3. Machines with recoil start: Turn engine ON/OFF switch to the “ON” position. Pull the recoil starter grip

lightly until resistance is felt, then pull briskly.

Machines without APR (Automatic Pressure Relief): If the engine fails to start after 1 or 2 pulls

of the recoil, pressure will build-up in the system. To relieve the pressure squeeze the gunvalve

trigger and allow water to flow freely. There should be NO nozzle or obstruction at the end of

the extension.

4. After engine starts, open choke gradually.

5. Warm up engine for 3 minutes without load.

2.2 Hose Connections (cont.)

www.simpsoncleaning.com

page 6