Intermediate Frame Snowthrowers

TP 300-4681-01-IW-SN 09/200714

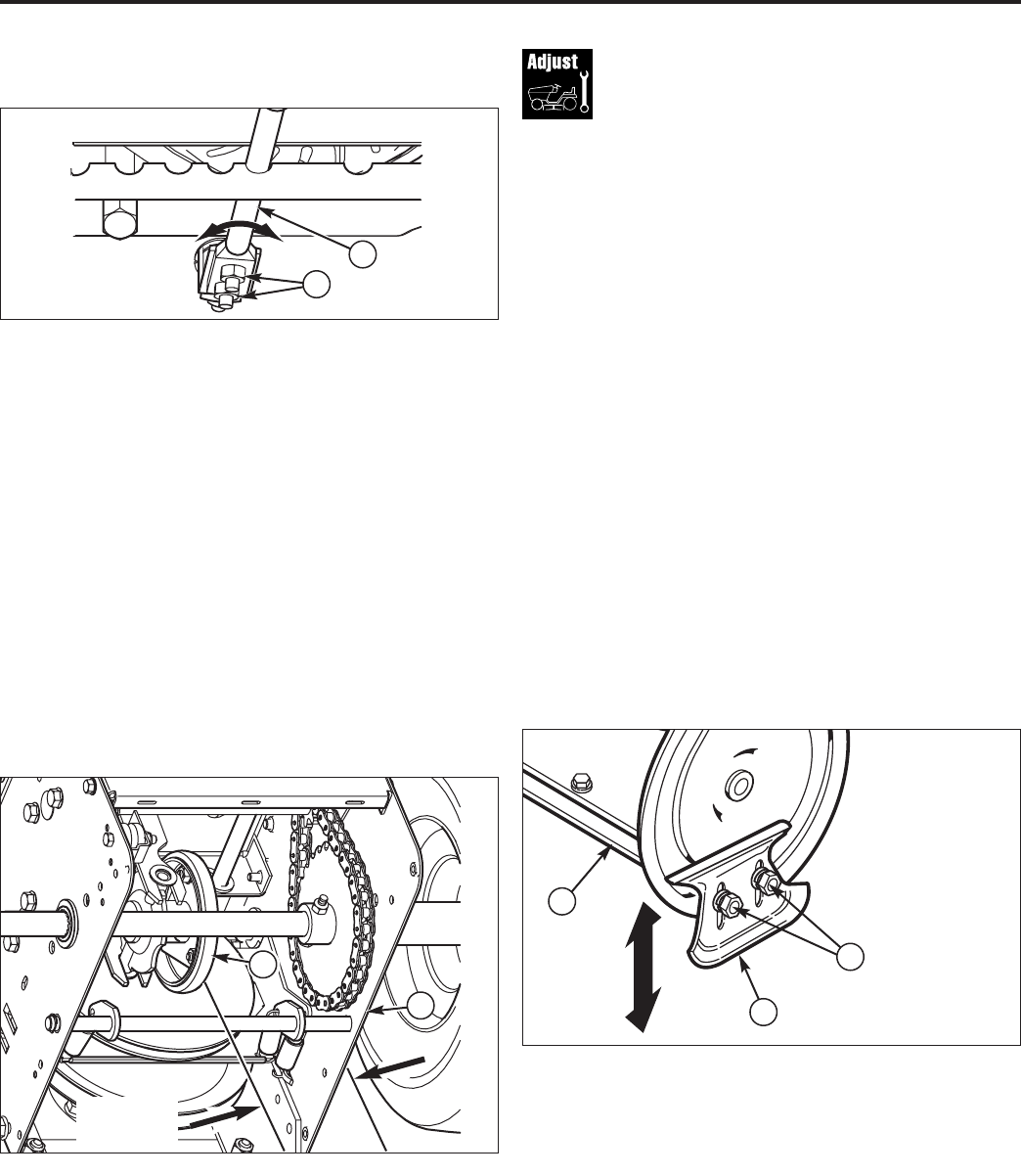

Figure 8. Skid Shoe Adjustment

A. Scraper Bar

B. Skid Shoe

C. Nuts

A

B

C

On smooth surfaces such as concrete or asphalt, the

scraper bar should scrape the surface. On surfaces such

as gravel, the scraper bar should be high enough so that

it will not pick up gravel or debris.

The height of the scraper bar is controlled by raising or

lowering the Skid Shoes (See Figure 8).

1. To raise the scraper bar height, rest the scraper bar on

a strip of wood equal in thickness to the desired height.

2. Make sure the scraper bar is parallel to the ground

surface.

3. Loosen the skid shoe nuts and let the skid shoes drop

to the surface.

4. Tighten the nuts, making sure the Skid Shoes are

adjusted equally and are parallel to the surface.

5. To lower the height of the scraper bar, raise the Skid

Shoes.

6. If the scraper bar becomes worn, it can be adjusted

by loosening the nuts and bolts attaching it to the

snowthrower, making the adjustment, and tightening

the hardware. It may also be replaced by removing

the mounting nuts and bolts attaching it to the

snowthrower.

Scraper Bar &

Skid Shoe Adjustment

7. Loosen shift lever nuts (B, Figure 6), and position the

shift speed lever (A) in the lowest forward speed.

Figure 6. Shift Lever Adjustment

A. Shift Lever

B. Nuts, 1/4-20

A

Figure 7. Friction Disc Measurement

A. Friction Wheel

B. Frame

4-5/16”

(10.95cm)

8. Note the position of the friction wheel (A, Figure 7).

The correct distance from the right side of the friction

wheel to the outside of the frame is 4-5/16” (10.95

cm). If the friction wheel is not in the correct position,

adjust as follows.

9. Move the friction wheel (A, Figure 7) to the correct

distance, 4-5/16” (10.95 cm).

10. Tighten the 1/4-20 shift lever nuts (B, Figure 6) to 60

lb-in. (6,8 Nm).

11. Check that the snowthrower operates in R1. If not

follow procedures 1-10 and readjust as necessary.

12. Install the bottom panel (B, Figure 5) and tighten the

capscrews (A).

A

B

B