5. Mount “V” belt in place on driven

pulleyas

shown

in figure 5 and attach spring

to

b&am

hole in the

spring holder and hook other end of the spring to the

idler

lever spring holder. Mount belt stop as shown

with

3/S”

bolt, flat washer, lockwasher and hex nut.

When idler pulley is engaged, l/S” clearance between

belt stop nud back of

“V”beltis

required. Note: “V”

‘belt

ru”s

uode,r idler pulley. See figure 5.

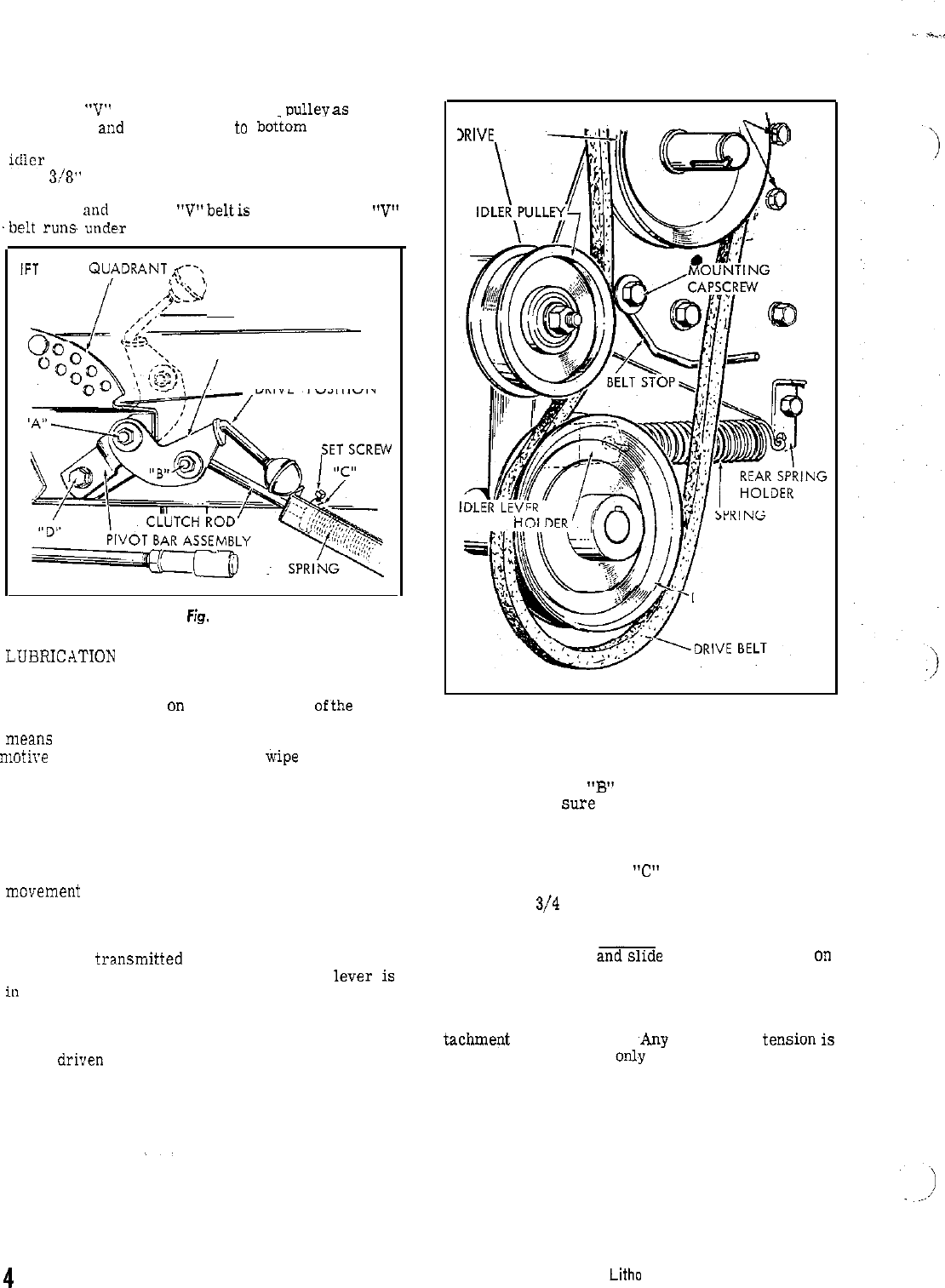

IFT LEVER QU,?DRANT

q‘\

/\~\

’

/

.,,,j&

“RELEASE” POSITION

CLUTCH LEVER ASSEMBLY

“DRIVE”, POSITION

F;s.

4

LUURICATION

The power take-off is lubricated by means of one

grease fitting located

on the bottomfront

ofthe

drive

‘bracket assembly. Occasionally apply grease by

means

of a standard grease gun loaded with auto-

motive

type grease. Be sure to wipe dirt and grit

from grease fitting before applying grease gun. Lu-

bricate all pivot points and idler pulley bearings with

SAE 20 oil every few hours of operation.

OPERATION

Operation of the power take-off is controlled by

m”veme”t

of the clutch lever assembly. See figure

4. When the clutch lever is in the forward raised

position, the clutch rod releases the tension holding

the idler pulley against the drive belt, and power

will not be

transmitted

to the driven pulley of the

power take-off assembly. when the clutch

lever

iS

ia

the back, depressedposition, theclutchrodapplies

tension to the idler pulley and as the idler pulley

takes-up the slack in the drive belt, power is trans-

mitted from the drive pulley on bevel gear box shaft

to the

drive”

pulley of the power take-off. Figure 4

shows clutch lever in drive position.

BELT GUARD SUPPORT MTG. BOLTS

I

IRIVE

PULLEY

SPRING

K

DRIVEN PULLEY

Fig. 5

ADJUSTMENT

At points “A” and “B” of figure 4, check tightness of

hex nut to be

sure

that clutch lever assembly and

clutch rod are free to pivot without binding.

Place clutch lever in “drive” position and observe

clearance between collar

“C” (figure 4) and end of

bracket. This clearance should normally be ap-

proximately

3/4

inch; at this setting the idler pulley

should be snugly against the drive belt. If additional

tension is required, release clutch lever and loosen

set screw on collar

andslide

collar farther back on

clutch rod. Retighten set screw in collar and put

clutch lever in drive position. Recheck clearance.

The tension of the idler pulley against the drive belt

must be sufficient to operate whichever tractor at-

tachme@

is being used. ,Any additional

tension

iS

unnecessary and will

only cause premature failure

of belts and idler pulley bearings.

4

Litho in USA

Form MF-49