Adjustments

21

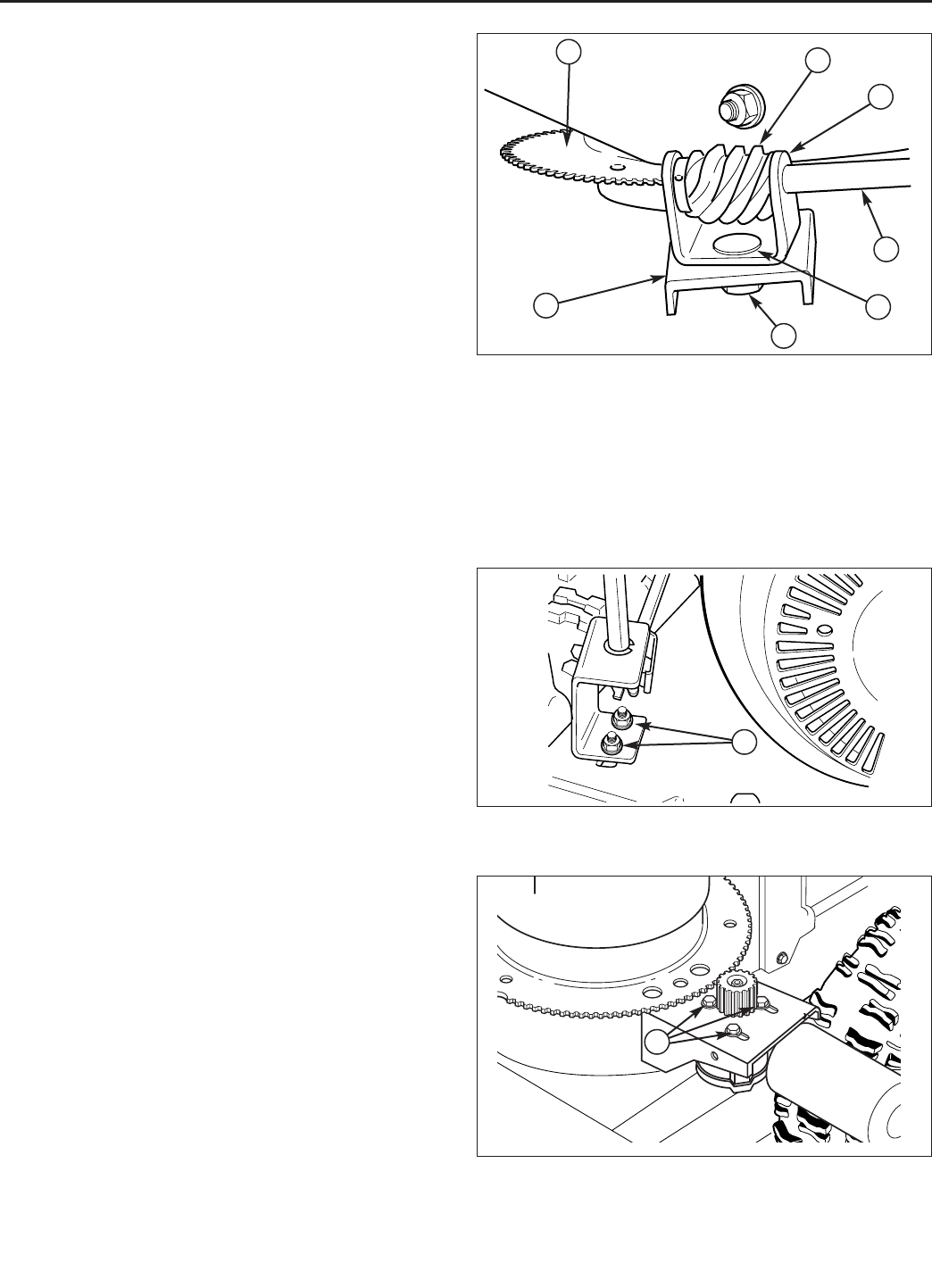

MANUAL DISCHARGE CHUTE

CONTROL LINKAGE ADJUSTMENT

Pinion Gear Adjustment

If the discharge chute is difficult to operate, first lubricate

the pinion gear (A, Figure 17) and ring gear (F). If it is

still difficult to operate, adjust as follows:

NOTE: If the discharge chute will not stay in position,

adjust the pinion gear (A) closer to the ring gear.

1. Loosen the nut (G, Figure 17) which holds the pinion

gear bracket in the slotted hole.

2. If the pinion gear is too tight against the ring gear,

move it away slightly and then retighten the nut.

3. Check the operation again

Figure 17. Discharge Control

A. Pinion Gear

B. Control Rod

C. Carriage Bolt

D. Slotted Bracket

E. U-shaped Bracket

F. Ring Gear

G. Nut

Figure 18. Gear Bracket Adjustment

A. Mounting Hardware

Gear Bracket Adjustment

If the Discharge Chute becomes difficult to rotate or

begins to operate erratically, the Chute Direction Control

rod gears may require adjustment:

1. Loosen the gear bracket mounting nuts (Figure 18).

2. Slide the gear bracket into the position that provides

the best engagement between the gears.

3. Tighten the bracket mounting hardware, and check

for smooth operation.

4. Readjust if necessary.

5. Lubricate the Chute Direction Control rod gears with

a medium weight (10W) oil

B

C

Figure 19. Chute Rotator Motor Adjustment

A. Capscrews

G

A

E

F

D

ELECTRIC DISCHARGE CHUTE

ROTATOR MOTOR ADJUSTMENT

If the electric chute rotator does not function properly,

check the electrical connections and then perform the

procedure below.

1. Remove the rotator motor cover.

2. Lubricate the chute ring gear.

3. Loosen the capscrews (A, Figure 19) securing the

rotator motor and adjust so that the motor gear and

chute ring gear mesh. Tighten the capscrews.

4. Reinstall the rotator motor cover.

A

A