14

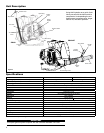

Install the lter element, pre-lter 6.

and cover in the reverse order of

removal.

To remove the cover, loosen the

thumbscrews and lift.

Air Cleaner

Element

Cover

Figure 19

Pre-Filter

Thumbscrews

Daily Maintenance

WARNING!

To reduce re hazard, keep

the engine and mufer free of dirt,

debris, and leaves.

Every 10 Hours

(more frequently in dusty conditions)

CAUTION!

Never operate the blower if the air

cleaner assembly is damaged or

missing!

Inspect the engine, tank, and hoses ■

for possible fuel leaks, and repair

as necessary.

Inspect the entire blower for loose,

■

damaged, or missing components,

and repair as necessary.

Carefully remove any accumula-

■

tions of dirt or debris from the

mufer and fuel tank. Dirt build-up

in these areas can lead to engine

overheating, re or premature wear.

IMPORTANT!

Direct the air stream at the inside face

of the lter only!

CAUTION!

The engine is cooled by air drawn

into the air intake cover on the

blower housing. The blower fan then

pushes the cooling air through an

opening in the fan housing, forcing it

past the cylinder cooling ns. Failure

to keep the cooling system and its

passages clear of debris will likely

result in engine overheating, a major

cause of serious engine problems

that can lead to failure.

Prior to each workday, perform the

following:

Remove all dirt and debris from

■

blower exterior and the engine.

Check the cooling ns and air

cleaner for clogging and clean as

necessary.

Remove the air cleaner cover by 1.

loosening the thumbscrews and lift-

ing. See Figure 19.

Remove and inspect the pre-lter. 2.

If the pre-lter is torn or otherwise

damaged, replace it with a new one.

Clean the pre-lter with soap and 3.

water. Let dry before reinstalling.

Inspect the air cleaner element. If 4.

the element is damaged or distorted,

replace it with a new one.

Tap lter gently on a hard surface to 5.

dislodge debris from element or use

compressed air from the inside to

blow debris out and away from the air

lter element.

IMPORTANT!

The blower uses a special high capac-

ity dry-type air lter element. The lter

should not be cleaned with a liquid

cleaner and must NEVER be oiled!

Maintenance (continued)

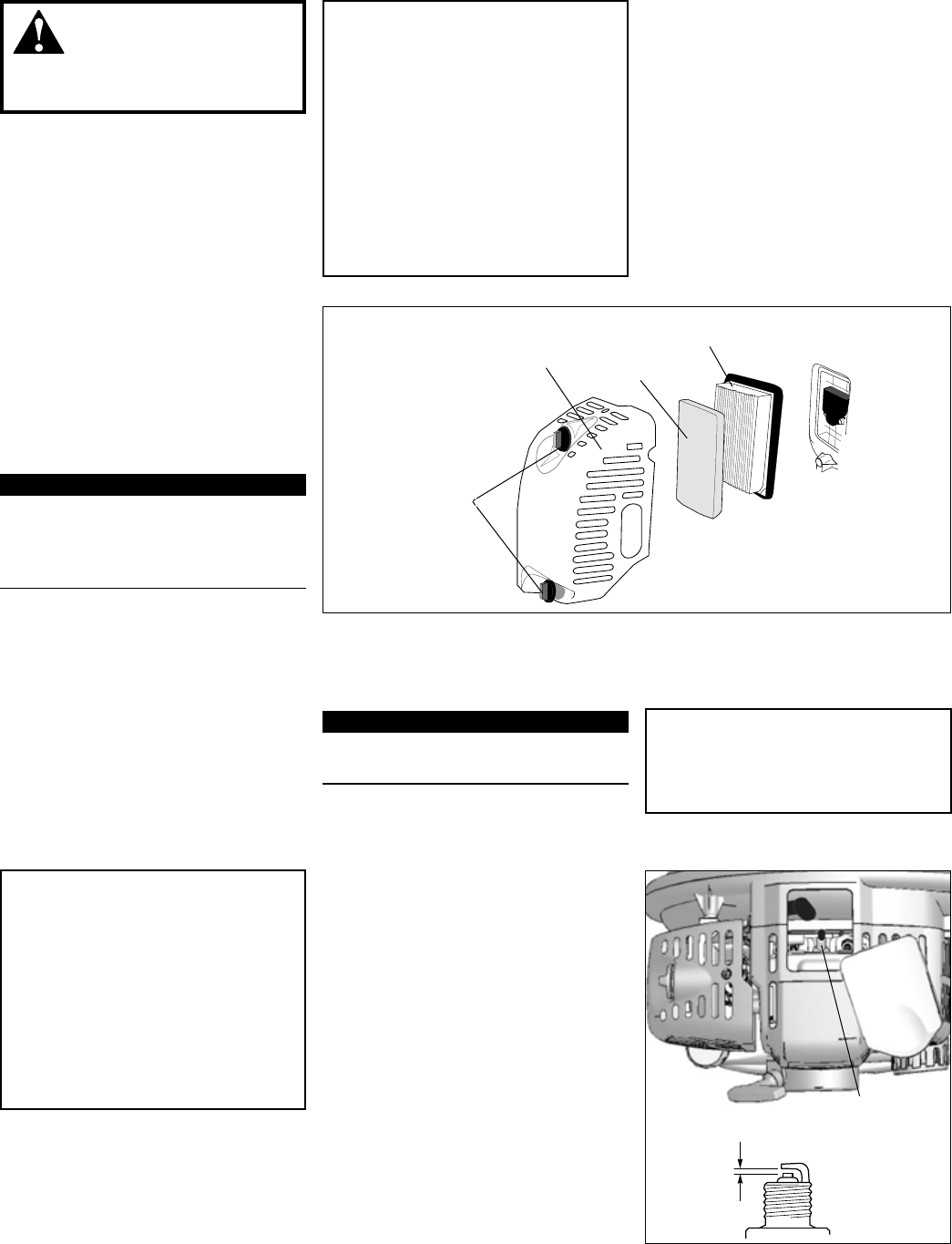

Counter-clockwise

to remove.

Clean the spark

plug and check

the gap at the

electrode.

spark plug gap--all models

0.6 mm

(0.024 in.)

Figure 20

NGK CMR5H

Every 10/15 Hours

CAUTION!

Never allow dirt or debris to enter

the cylinder bore! Before removing

the spark plug, thoroughly clean the

spark plug and cylinder head area!

Allow the engine to cool before

servicing the spark plug! Cylinder

threads can be damaged by tighten-

ing or loosening the spark plug while

the engine is hot!

Use the spark plug wrench to 1.

remove the spark plug. (See Figure

20)

Clean and adjust the spark plug gap 2.

to 0.6mm (0.024”). If the plug must

be replaced, use a NGK CMR5H or

equivalent type plug of the correct

heat range.

Install the spark plug nger-tight in 3.

the cylinder head, then tighten it

rmly with the spark plug wrench. If

a torque wrench is available, torque

the spark plug to 16.7-18.6 Nm

(148-165 inch- pounds).

Replace the spark plug annually:

■

Use only NGK CMR5H or equivalent

resistor type spark plug of the cor-

rect heat range. Set spark plug elec-

trode gap to 0.6 mm (0.024 inch)

.