16

Maintenance (continued)

10-Hour maintenance

(more frequently in dusty conditions)

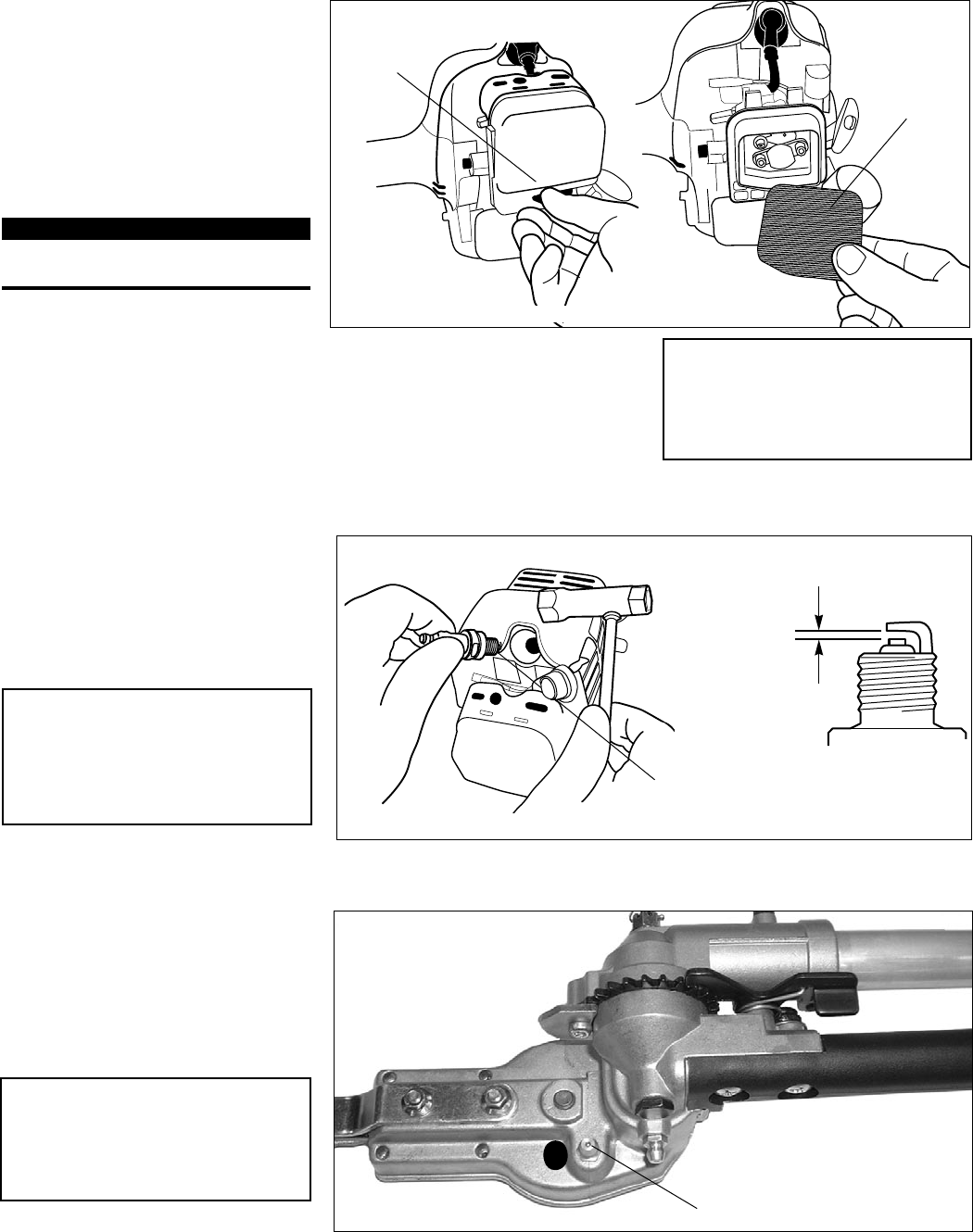

Remove the air cleaner cover by 1.

loosening the cover screw(s) and

lifting.

Remove the air cleaner element. 2.

In dusty applications the lter

■

should be gently blown out with

compressed air daily or 2 to 3 times

per week.

CAUTION!

Never operate the unit if the air

cleaner assembly is damaged or

missing!

Unscrew

Fasteners

Loosen air cleaner cover screws

Air Filter

Element

Lubricate cutter assembly and gearcase

Gearcase

grease tting

A

Lubricate the cutter assembly ■

gearcase by pumping one or two

strokes of lithium-base grease into

the grease tting (A) using a lever-

type grease gun.

CAUTION!

Before removing the spark plug,

clean the area around the plug to

prevent dirt and debris from getting

into the engine’s internal parts.

10/15-Hour maintenance

Remove and inspect spark plug

CAUTION!

Over lubricating can cause the gear-

case to operate sluggishly and can

cause grease to leak out.

Gearcase lubrication

Remove and clean or replace the

spark plug.

Adjust the spark plug electrode gap to ■

0.6 mm (0.024 inch). If the spark plug

must be replaced, use only an NGK

BPM8RY spark plug.

spark plug gap--all models

Clean the spark plug

and check the gap at

the electrode.

0.6 mm

(0.024 inch)

IMPORTANT!

Direct the air stream at the inside face

of the lter only!

Once each week the lter should

■

be cleaned with a petroleum sol-

vent such as mineral spirits to

loosen and ush out debris trapped

between the lter halves. Allow the

lter to dry thoroughly before using

again. When the felt becomes

unraveled the lter should be

replaced.

Replace air cleaner element and 3.

cover.