AH231_18

AH231_18

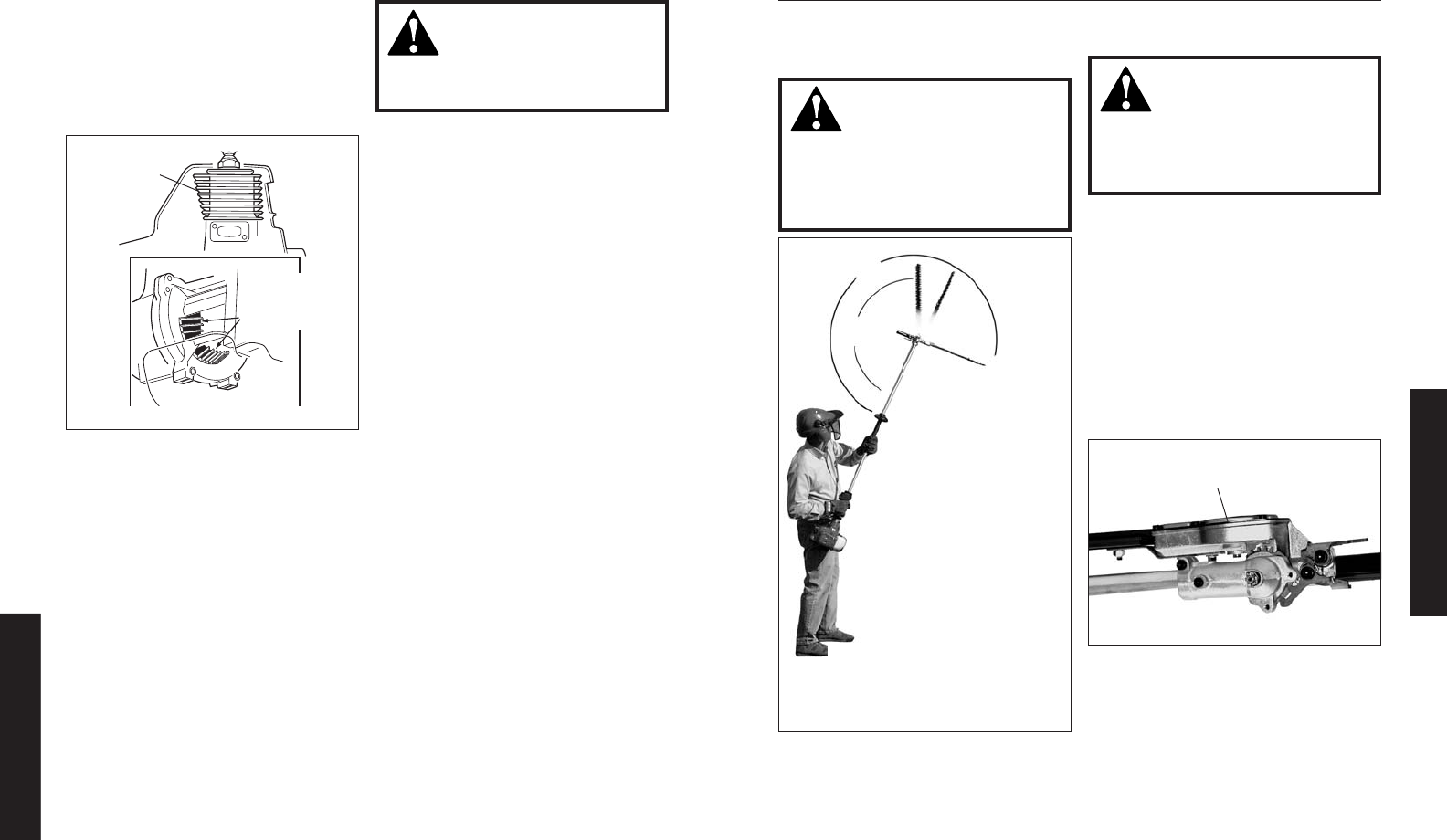

Adjusting the Hedge Trimmer

Cutter Assembly for Desired

Cutting Angles

Figure 14

Figure 15

Various blade

positions

possible

Gearcase rotated to the

storage/transportation position

270

°

120

°

14

Adjusting the Cutter Assembly

for Storage or Transportation

WARNING!

Do not touch the cutter blades

when the engine is running. The

blades can oscillate even if the

engine is idling.

The cutter assembly

can be adjusted to 10

different positions

ranging from 120° to

270° from the outer

tube as shown in

Figure 14. Refer to the

steps on the previous

page for adjustment

procedures. Always

make sure the lock

latch is securely

locked after each

adjustment.

WARNING!

Never run the engine when

adjusting the cutter assembly to

the storage position.

1. With the engine off, install the

scabbard onto the blade.

2. Using the procedures described on

the previous page, rotate the cutter

assembly so it is parallel to the

tube. Make sure the latch lock and

the latch release return securely to

a locking position. See Figure 15.

3. Make sure the scabbard is in place

on the cutters before storing or

transporting.

OPERATION

AH231_29

Prior to each work day, perform the

following:

■ Remove all dirt and debris from the

engine, check the cooling fins and

air cleaner for clogging, and clean

as necessary. See Figure 24.

Daily Maintenance

■ Carefully remove any accumulations

of dirt or debris from the muffler and

fuel tank. Check cooling air intake

area at base of crankcase. Remove

all debris. Dirt build-up in these areas

can lead to engine overheating, fire,

or premature wear.

Figure 24

Keep cooling

fins clean

Keep air

passages

clean

WARNING!

Always wear gloves when working

around the cutter assembly.

■ Clean any debris or dirt from the

hedge trimmer cutter blades.

Lubricate the blades before use and

after refueling. Check the cutters for

damage or incorrect adjustment.

■ Check for loose or missing screws or

components. Make sure the cutter

attachment is securely fastened.

■ Check the entire unit for leaking

fuel or grease.

■ Make sure nuts, bolts, and screws

(except carburetor adjusting

screws) are tight.

21

MAINTENANCE