Maintenance Section 5-8

FM6072 08/01

© 2004 Alamo Group Inc.

MAINTENANCE

MAINTENANCE

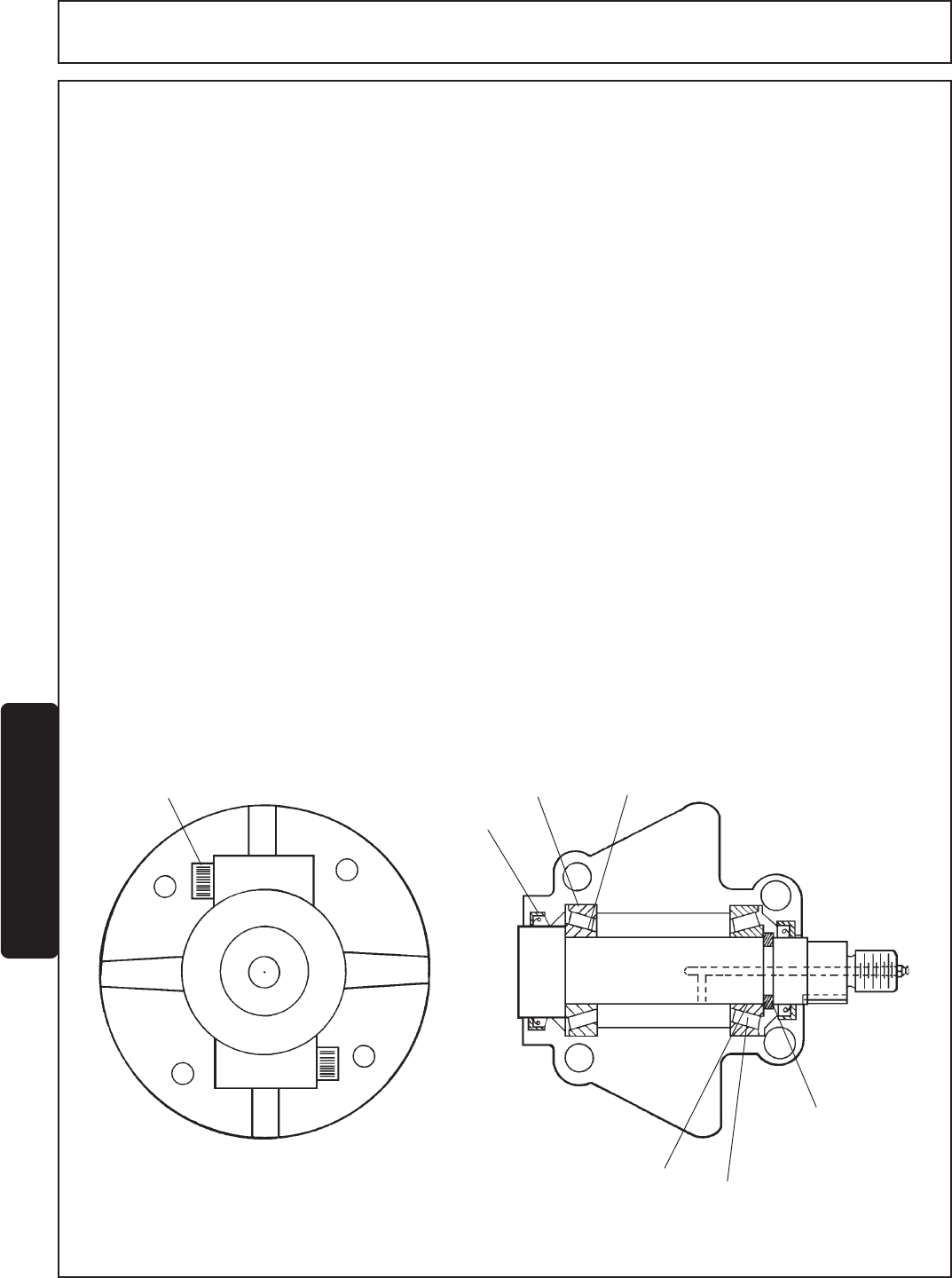

BLADE SPINDLE SERVICE INSTRUCTIONS Figure 9

DISASSEMBLY

1. Remove 4 capscrews (#1) from housing. Tap with plastic or wood hammer to break halves apart. Lay top

half aside.

2. Remove complete shaft assembly from other housing half. Remove seals (#2) from each end of shaft.

Remove retaining ring (#3) near top end of shaft. Press bearings and cups from shaft.

ASSEMBLY

1. Assemble all parts in reverse order that they were removed.

2. Press lower roller bearing (#5) onto shaft. NOTE: Tapered rollers should point toward center of shaft. Install

lower bearing cup (#4).

3. Drop upper bearing cup (#4) over shaft. NOTE: Small ID of cup should face toward lower cup. Press top

bearing into place and install retaining ring(#3).

4. Lubricate seal ID and tap top shaft end with plastic tape to cover sharp edge. Slide seal over each shaft end.

5. Place shaft assembly into one half of housing. Place 1/16 inch bead of gasket compound on both sides of

housing half.

6. Install other half of housing and install capscrews. Torque capscrews evenly to 15-20 ft-lb. torque.

1

4

5

4

5

2

3

FIGURE 9