OPERATING INSTRUCTIONS (cont'd)

TO

t.

2.

REPAIR BROKEN cUTTING LINE

5.

6.

7.

StOp the motor an unplug power cord.

Visible cutting fine can be retrieved with needle nosed pliers.

3. Hub should be depressed and released while keeping tension

on the cutting line. One inch o_ cutting line should feed each

time the hub is depressed.

4. If cutting line cannot be retrieved, follow instructions under

SPOOL REPLACEMENT.

SPOOL REPLACEMENT

1. Stop motorand unplug power cord.

2. Restrainrear plate_pushintookbutton (located onhub),andtwist

Ilub counter-clockwiseuntil locking bbs disengage.Removehub.

3. Rereove spool from assembly a_ndremovespring from spool

4. Rewindspooiinacco_ancewiththeinstructionsincludedherein

(fig. 8) or replace spool as appropriat_

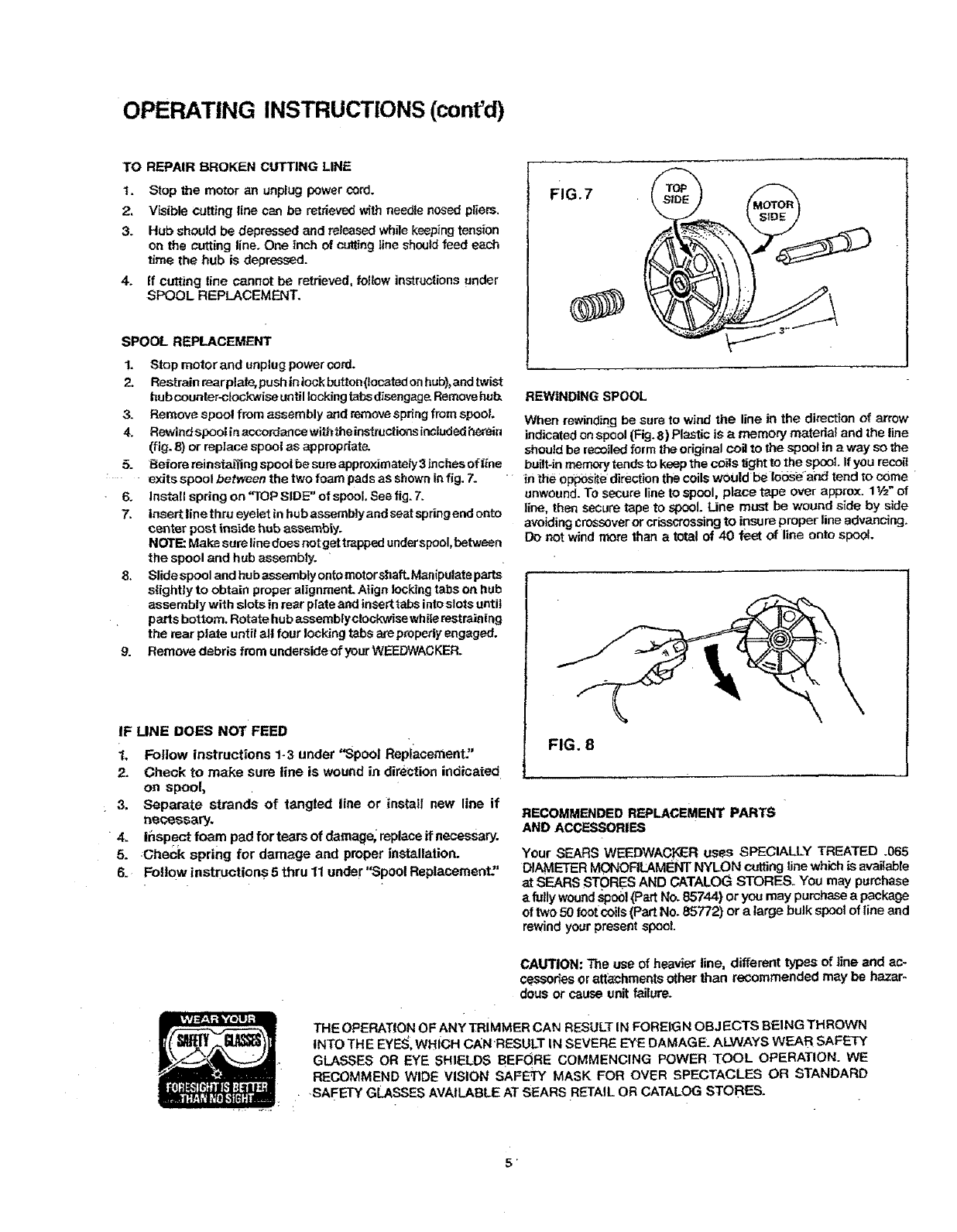

Before reinstallingspooi be sureapproximately :3inchesof |ine

exits spool between the two foam padsasshown in fig. 7. "

Install spring on "TOPSIDE" of spool. Seefig. 7.

insertline thrueyeletin hub assemblyandseatspringendonto

center post inside hub assembly.

NOTE:Make surelinedoes notgettmppedunderspool, between

the spool and hub assembly.

=

8. Slidespooland hubassemblyontomotorst=aft.Manlpulate parts

siightiy to obtain proper alignment.Align lockingtabson hub

assembly with slots inrear plateand insert tabs intostotsuntil

parts bottom, Rotate hubassembly clockwisewhile restraining

the rear plate until all four lockingtabsareproperlyengaged.

9. Remove debris from undersideof yourWEEDWACKER.

IF LINE DOES NOT FEED

1, Follow instructions 1-3 under "Spool Replacement:'

2. Check to make sure line is wound in direction indicated

on spool,

3. Separate strands of tangled Itne or install new line if

t_ecessary,

4. inspect foam pad for tears of damage, replace if necessary.

5. Check spring for damage and proper installation.

6. Follow instructions 5 thru 11under "Spool Replacement."

REWINDING SPOOL

When rewind_g be sure to wind the line in the direct|on of arrow

indicatedonspool{Fig.8) Plastic isa memory malaria!and the line

should berecoiledformtheoriginalcoil to the spoolina way so the

built-in memorytendstokeepthe coilstightto the spool. If you recoil

in tileo_ite directionthecoils w0uld be 100SOai'_ tend to come

unwound.Tosecure lineto spool, place tape over approx. 11/2"of

!ine, then securetapeto spool. Line must be wound side by side

avoiding crossoveror crisscrossingto insure proper lineadvancing.

Do not wind more than a total of 40 feet of line onto spool.

FIG. 8

RECOMMENDED REPLACEME_ PARTS

AND ACCESSORIES

Your SEARS WEEDWACKJERuses SPECIALLY TREATED .065

DIAMETER MONORLAMENT NYLON cutting linewhichis available

at SEARS STORES AND CATALOG STORES. You may purchase

a fullywoundspoo!(PartNo. 85744) or you may purchasea package

oftwo50 foot coils(Part No.85772) or a large bulk spool of line and

rewind yourpresent spool.

CAUTION: The use of heavier line, different types of line and ac-

cessoriesorattachments other than recommended may be hazar-

dous or cause unitfailure.

THE OPERATION OF ANY TRIMMER CAN RESULT IN FOREIGN OBJECTS BEING THROWN

INTO THE EYES,WHICH CAN'RESULT IN SEVERE EYE DAMAGE. ALVVAYS WEAR SAFETY

GLASSES OR EYE SHIELDS BEFORE COMMENCING POWER TOOL OPERATION. WE

RECOMMEND WIDE VISION SAFETY MASK FOR OVER SPECTACLES OR STANDARD

• .SAFETY GLASSES AVAILABLE ATSEARS RETA L OR CATALOG STORES.

5'