20

R

Section 6

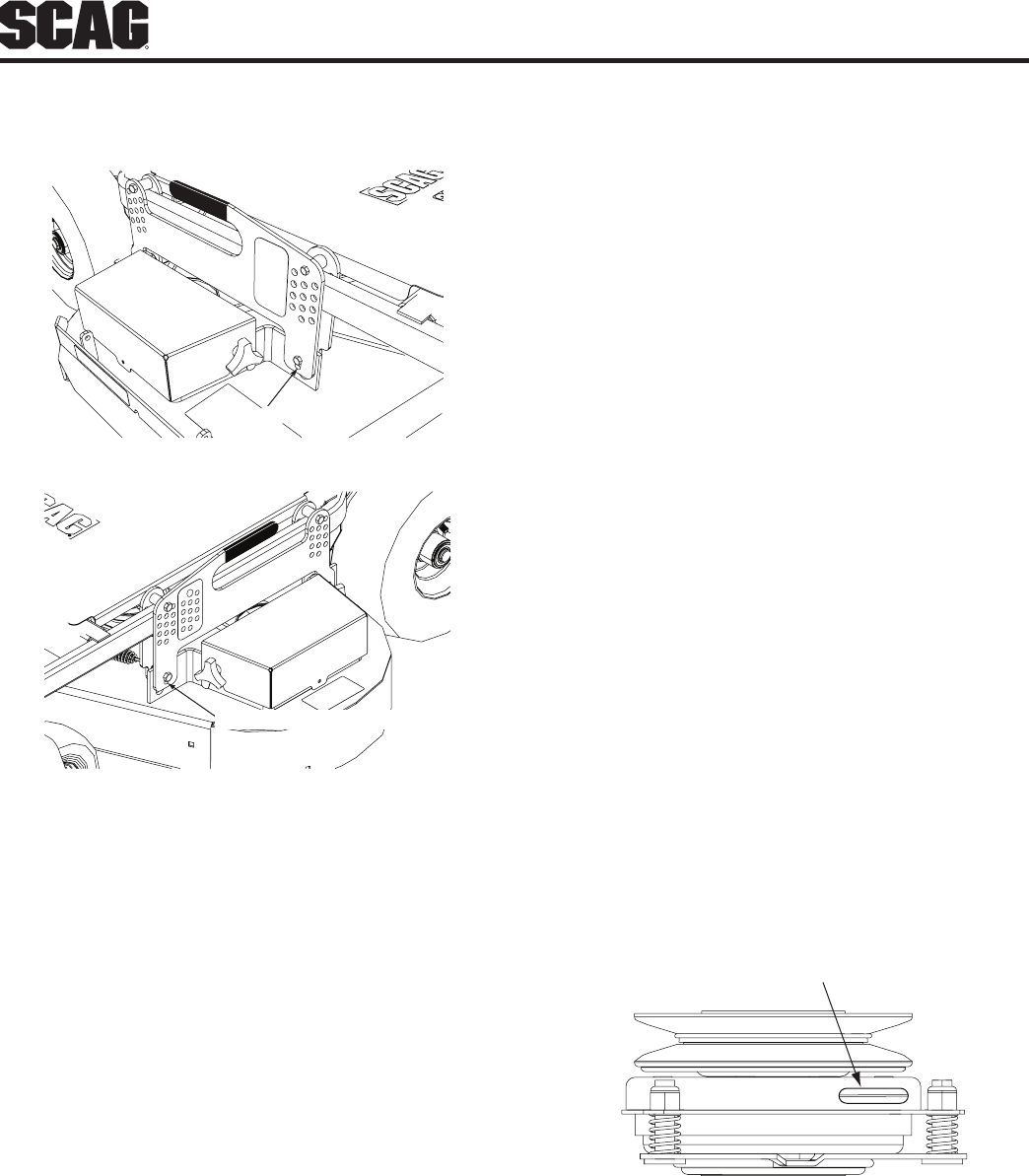

On the front of the cutter deck locate the cutter deck 1.

adjustment slots. See Figure 6-2.

ADJUSTMENT SLOT

ADJUSTMENT SLOT

Cutter Deck Adjustment SlotsFigure 6-2.

Loosen the two (2) elastic stop nuts. Adjust the cutter 2.

deck up or down in the adjustment slot to adjust until

the distance from the top of the cutter deck to the

floor is the same as the measurement on both sides

of the machine.

Tighten the two (2) elastic stop nuts to secure the 3.

cutter deck in the proper position.

CUTTER DECK PITCH

The pitch of the cutter deck should be equal between

the front and rear of the cutter deck for proper cutting

performance. To check for proper deck pitch, be sure

that the mower is on a flat, level surface and the tires are

properly inflated.

Check the distance from the top of the cutter deck to the

floor at the rear RH side of the cutter deck directly behind

the cutter deck height adjustment bracket. Next check

the distance from the top of the cutter deck to the floor at

the front RH side of the cutter deck directly in front of the

cutter deck height adjustment bracket. The measurement

at the front of the cutter deck should be the same as the

rear of the deck. Make these measurements at the LH side

of the cutter deck also. If the measurement at the front of

the deck is not the same, the cutter deck pitch must be

adjusted as follows:

Loosen the two (2) elastic stop nuts. Adjust the cutter

1.

deck up or down in the adjustment slot to adjust until

the distance from the top of the cutter deck to the

floor is the same as the measurement on both sides

of the machine.

Tighten the two (2) elastic stop nuts to secure the 2.

cutter deck in the proper position.

ELECTRIC CLUTCH ADJUSTMENT6.6

The electric clutch serves two functions in the operation of

the mower. In addition to starting and stopping the power

flow to the cutter blades, the clutch also acts as a brake to

assist in stopping blade rotation when the PTO is switched

off or the operator presence circuit is interrupted.

When the clutch is disengaged, the air gap between the

armature and rotor must be adjusted to fifteen thousandths

of an inch, 0.015, for proper operation. The airgap

adjustment is made at three bolts on the clutch. There are

three inspection windows, one next to each adjusting bolt.

See Figure 6-3.

INSPECTION WINDOW (x3)

Clutch Air Gap AdjustmentFigure 6-3.

Locate the inspection windows on the clutch.1.

Place a 0.015 feeler gauge in the slot between the 2.

rotor and the armature. See Figure 6-4.