16

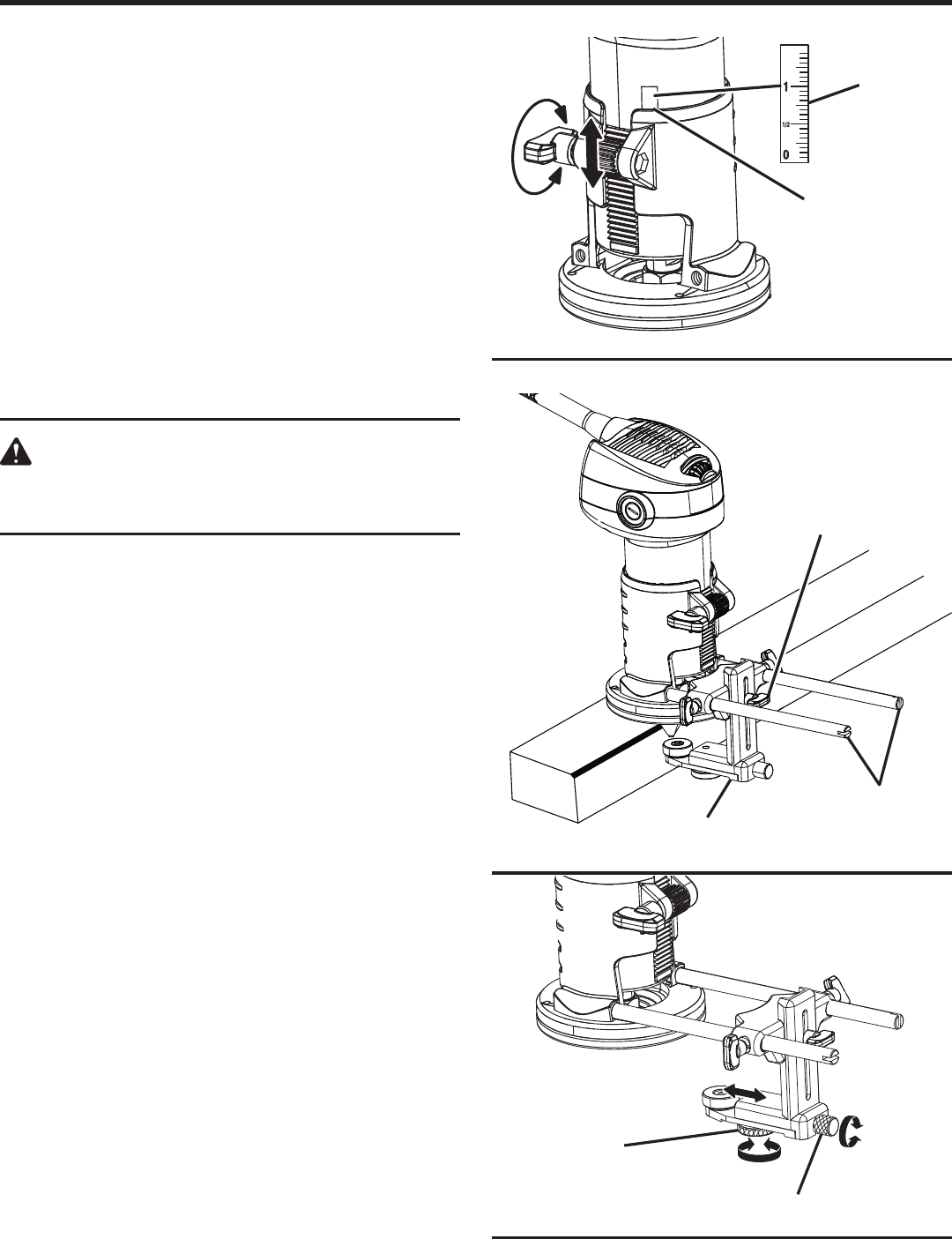

SETTING DEPTH OF CUT

See Figure 11.

n Unplug the laminate trimmer.

n Rotate the depth adjustment knob counterclockwise.

n Slide the motor housing section of the trimmer upward

until the tip of the cutter reaches the work surface. The

depth of cut is zero at this point.

n Adjust the position of the trimmer to obtain the desired

depth of cut by moving the motor housing section up or

down. The cutter depth can be read on the depth of cut

scale. Each mark on the scale indicates a 1/16 in. change

in depth setting. Use the top edge of the die-cast base

(depth of cut indicator) as reference when setting depth

of cut.

n Tighten the depth adjustment knob by turning clock-

wise.

WARNING:

Avoid open area of trimmer base. Serious personal

injury will result from contact with a rotating

cutter.

TO USE BEARING GUIDE ASSEMBLY

See Figures 12 - 13.

���Use the bearing guide to trim laminates without the need

for a bearing bit.

n Unplug the laminate trimmer.

n Thread guide bars into the base and tighten with a flat

head screwdriver.

n Slide bearing guide assembly onto the guide bars.

n Loosen the middle thumb screw to lower or raise the

bearing. The bearing should be approximately 1/2 in.

below the end of the bit.

n Tighten the middle thumb screw.

n Position the trimmer on the workpiece to find the approxi-

mate placement of the bearing guide. The bit should be

touching the edge of the workpiece.

n Tighten the two outside thumb screws.

n Use the micro adjust screw to fine tune the cutter place-

ment.

n Loosen the bottom thumb wheel.

n Turn the micro adjust screw clockwise to move the

bit closer to the workpiece. Turn the micro adjust

screw counterclockwise to move the bit away from the

workpiece.

n Tighten the bottom thumb wheel.

OPERATION

Fig. 11

Fig. 12

Fig. 13

BEARING GUIDE

ASSEMBLY

MIDDLE THUMB

SCREW

GUIDE BARS

DEPTH OF CUT

SCALE

BOTTOM THUMB

WHEEL

MICRO ADJUST

SCREW

DEPTH OF CUT

INDICATOR