5

108136

OWNER’S MANUAL

UNPACKING

1. Remove all items from carton.

2. Check all items for any shipping dam-

age. If you find any damage or if any

parts are missing, promptly inform

dealer where you bought the Pole Saw.

ASSEMBLY

The plastic hardware bag for the Pole Saw

should include the following:

CHAIN SAW HARDWARE

• (2) Guidebar bolts

• (2) Guidebar nuts

• (1) Phillips self tapping screw

• (1) Saw chain

• (1) Guide bar

• (1) Hand guard

• (1) Scabbard

POLE SAW HARDWARE

• (1) Handle bracket

• (4) #10 x 24 Phillips screws

• (4) #10 lockwashers

ASSEMBLY OF CHAIN SAW

Assemble the chain saw before assembling

the pole. Refer to chain saw manual for

assembly instructions.

POLE SAW NAMES

AND TERMS

Coupling Nut Threaded collar (loosen to

slide inner pole, tighten to hold pole in

position).

Guide Bar Metal bar that extends from

saw body. The guide bar supports and guides

chain.

Inner Pole The moveable section of tub-

ing to which the saw is attached.

Kickback Quick backward and upward

motion of guide bar. Kickback may occur

when tip of guide bar touches an object

while chain is moving. The guide bar will

kick up and back towards operator.

Oiler Control System for oiling guide bar

and chain.

Outer Pole Retains the moveable inner

pole.

Saw Chain (Chain) Loop of chain having

cutting teeth for cutting wood. The motor

drives chain. The guide bar supports chain.

Sprocket Toothed wheel that drives chain.

Switch Device that completes or interrupts

electrical circuit to motor of saw.

Switch Lockout Device that reduces

accidental starting of saw.

Trigger Device that turns saw on and off.

Squeezing trigger turns saw on.

Releasing trigger turns saw off.

Trimming (Pruning) Process of cutting

limb(s) from a living tree.

Undercut An upward cut from underside

of log or limb. This is done while in normal

cutting position and cutting with top of

guide bar.

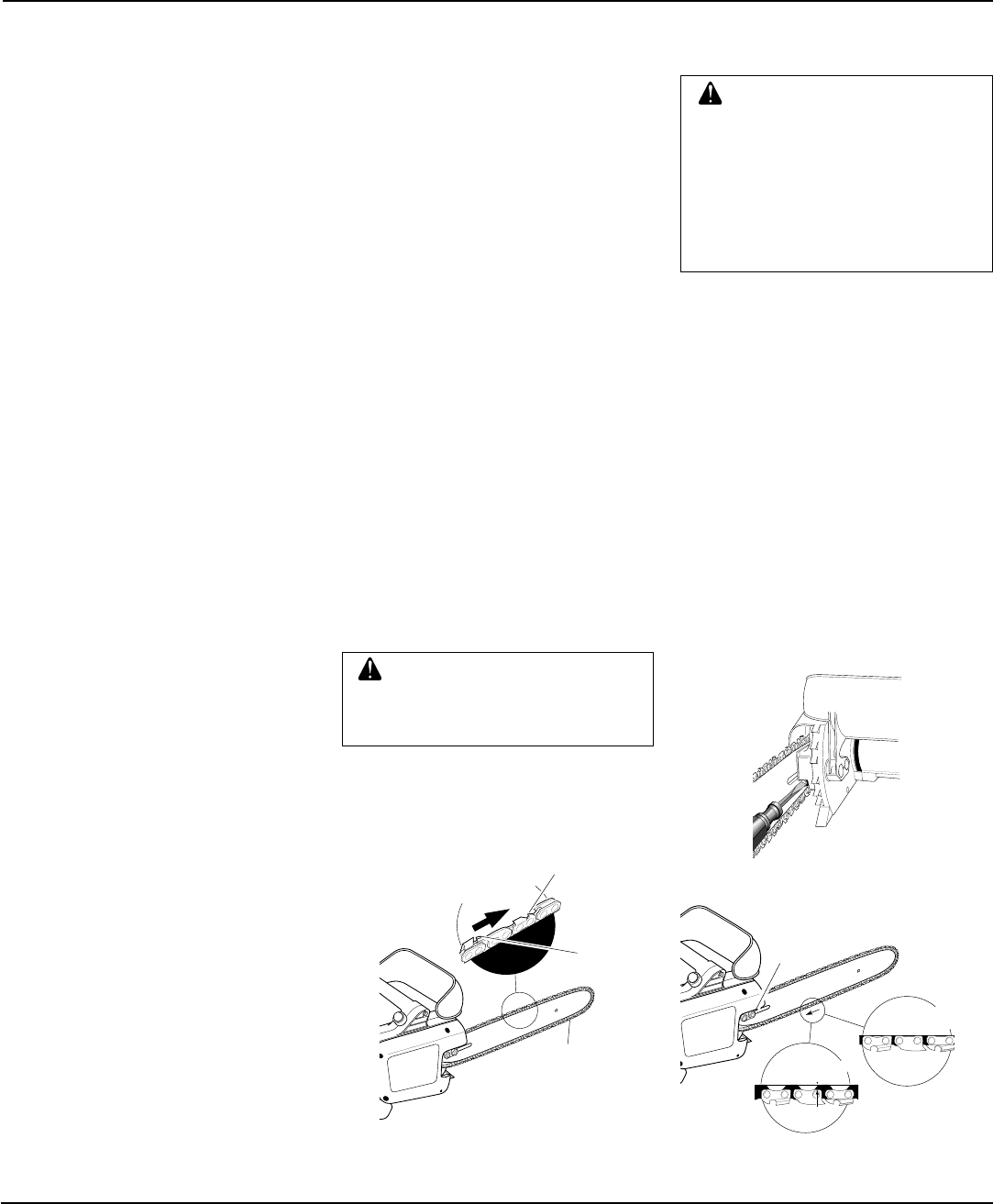

CAUTION: Do not place chain

on saw backwards. If chain is

backwards, saw will vibrate badly

and will not cut.

Make sure cutting edges of chain are facing

in the right direction. Position chain so cut-

ting edges on top of guide bar face guide bar

nose (see Figure 2).

SAW CHAIN TENSION

ADJUSTMENT

WARNING: Maintain proper

chain tension. A loose chain will

increase the risk of kick back. A

loose chain may jump out of

guide bar groove. This may in-

jure operator and damage chain.

A loose chain will cause chain,

guide bar and sprocket to wear

rapidly.

1. To adjust chain tension, make sure

guide bar nuts are only finger tight.

Also make sure adjusting block is in

oval adjusting hole on guide bar.

2. Turn adjusting screw clockwise until

all slack is out of chain.

Note:

There

should be no gap between side links of

chain and bottom of guide bar.

3. Wearing protective gloves, move chain

around guide bar. Chain should move

freely. If chain does not move freely,

loosen chain by turning adjusting screw

counterclockwise.

4. After chain tension is correct, tighten

guide bar nuts firmly. If not, guide bar

will move and loosen chain tension.

This will increase the risk of kickback.

This can also damage saw.

Figure 4 - Saw Chain Adjustment

Correct

Tension

Gap

Incorrect Tension

Guide Bar

Nuts

Guide Bar

Guide Bar

Figure 3 - Turning Adjusting Screw

Towards

Guide Bar

Nose

Cutting

Edge

Cutting

Edge

Saw

Chain

Figure 2 - Chain Position

Continued