14

To adjust the temperature:

1. Both isolation valves must be fully open.

2. Adjust Bypass Valve "A" 1/2 open and Balancing

Valve "B" fully open. (See piping configuration

page 15, 16 & 17)

3. Fire your Raypak pool heater and adjust Bypass

Valve "A" to obtain a heater inlet temperature

approximately 105°F. Turning Valve A in the open

direction will raise the heater inlet temperature and

closing Valve "A" will lower the heater inlet temper-

ature.

4. If the heater inlet temperature remains less than

100°F and Valve "A" is fully open, leave Valve "A"

fully open and throttle Valve "B" until the heater

inlet temperature rises above 105°F.

5. The resultant heater outlet temperature should be

in the range of 120-130°F.

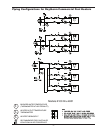

Fig. 22: Installation with Weld O Lets

NOTE: The drawings and instructions above show

only one of several acceptable ways of installing the

dry well into main system loop. The use of saddle

clamps and “Weld O Lets” (shown in Fig. 22) are

acceptable. Follow clamp manufacturer’s

instructions.

CAUTION: The inlet water temperature must be

kept above 105°F. Changes in system flow or valve

position may require re-adjustment of the flow

settings. Check the heater bypass settings after

making adjustments. Failure to maintain an inlet

temperature above 105°F may result in damage to

the heater. Failure to comply with this instruction

voids the warranty.

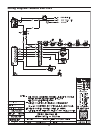

Mounting Well into System

Return Loop Pipe - Front-

Mounted Loop

1. Locate and mark an area on the main system

return loop pipe where the well is always exposed

to the water circulating back from the pool. See

Fig. 20.

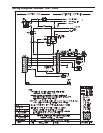

2. Shut off water and drain any water from the pipe

as necessary.

3. Drill a 23/32" diameter hole (½” NPT) into the pipe

as shown in Fig. 21.

4. Using a ½” NPT tap and appropriate handle,

thread the tap into the pipe.

5. Apply pipe dope as necessary to male threads of

well and insert into threaded hole. Do not over-

tighten well.

NOTE: For more detail on piping configurations for

large systems, refer to the diagrams on pages 15, 16

& 17.

HEATER

Fig. 20: Installation Location

Fig. 21: Drill Hole in Pipe for Dry Well