15

MAINTENANCE SCHEDULE

Check:

Fuel mixture level Before each use....

Bar lubrication Before each use.......

Chain tension Before each use.......

Chain sharpness Before e a ch use.....

For damaged parts Before each use...

For loose caps Before each use......

For loose fasteners Before e a ch use...

For loose parts Before each use......

Inspect and Clean:

Bar Before each use................

Complete saw After each use.......

Air filter Every 5 hours*.............

Chain brake Every 5 hours*.........

Spark arresting screen

and muffler Every 25 hours*..........

Replace spark plug Yearly.

Replace fuel filter Yearly...

* Hours of Operation --

Each hour of operation is approximately

2 tanks of f uel.

GENERAL RECOMMENDATIONS

The warranty on this unit does not cover items

that have been subjected to operator abuse or

negligence. To receive full value from the war-

ranty, the operator must maintain unit as in-

structed inthis manual. Various adjustments

will need to be made periodically to properly

maintain your unit.

S Once a year , replace the spark plug, air filter,

and check guide bar and chain for wear . A

new spark plug and air filter assures proper

air-fuel mixture and helps your engine run

better and last longer.

CHECK FOR DAMAGED OR

WORN PARTS

Contact an authorized service dealer for re-

placement of damaged or worn parts.

NOTE: It is normal for a smallamount of oil

to appear under the saw after engine stops.

Do not confuse this with a leaking oil tank.

S ON/STOP Swit ch -- Ensure ON/STOP

switch functions properly by moving the

switch to the STOP position. Make sure en-

gine stops; then restart engine and continue.

S Fuel Tank -- Do not use saw if fuel tank

shows signs of damage or leaks.

S Oil Tank -- Donot use saw if oiltank shows

signs of damage or leaks.

CHECK FOR LOOSE

FASTENERS A ND PARTS

S Bar Nuts

S Chain

S Muffler

S Cylinder Shield

S Air Filter

S Handle Screws

S Vibration Mounts

S Starter Housing

S Front Hand Guard

CHECK CHAIN SHARPNESS

A sharp chain makes wood chips. A dull

chain makes a sawdust powder and cuts

slowly. See CHAIN SHAR PENING.

CHECK GUIDE BAR

Conditions which require guide bar mainte-

nance:

S Saw cuts t o one side or at an angle.

S Saw has to be forced through the cut.

S Inadequate supply of oil to bar/chain.

Check the condition of guide bar each time

chain is sharpened. A worn guide bar will

damage the chain and make cutting difficult.

After each use, ensure ON/STOP switch is

in the STOP position, then clean all sawdust

from the guide ba r and sprocket hole.

To maintain guide bar:

S MoveON/STOPswitchtoSTOP.

S Loosen and remove bar knob completely by

lifting lever and turning counterclockwise.

S Loosen chain tension by turning adjusting

wheel (upward direction). Remove clutch

cove r.

S Remove bar and chain from saw.

S Clean the oil holes and bar groove after

each 5 hours of operation.

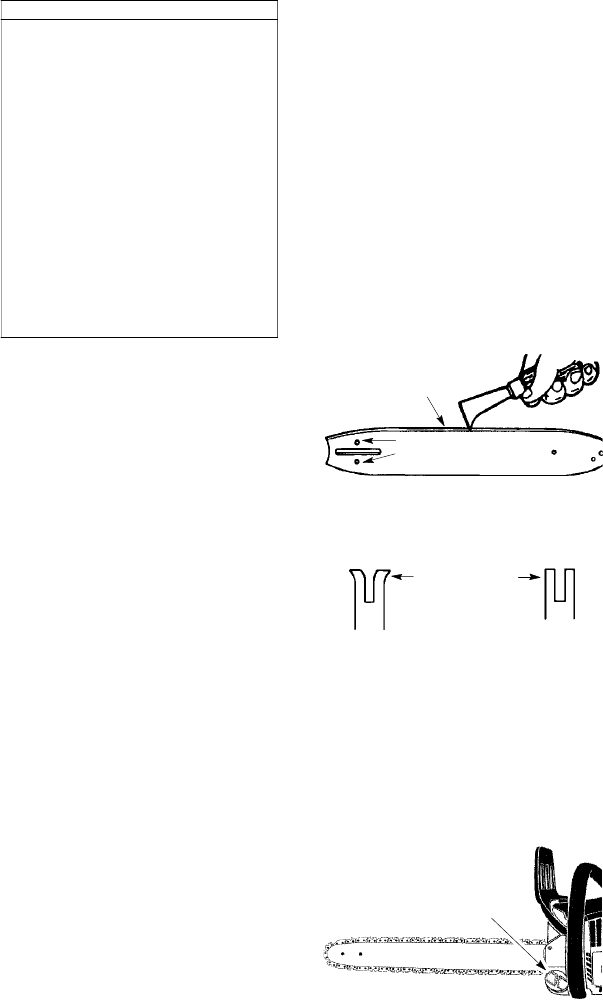

Remove Sawdust From

Guide Bar Groove

Oil Holes

S Burring of guide bar rails is a normal

process o f rail wear. Remove these burrs

with a flat file.

S When r ailtop i s uneven,usea flatfile tore-

store square edges and sides.

Correct GrooveWorn Groove

File Rail Edges

and Sides

Square

Replace guide bar when the groove is worn,

the guide bar is bent or cracked, or when ex-

cess heating or burring of the rails occurs. If re-

placement is necessary, use only the guidebar

specified for your saw in the repair parts list or

on the decal located on the chain saw.

CHECK FUEL MIXTURE LEVEL

S See FUELING ENGINE under the OP-

ERA TION section.

LUBRICATION

Bar Oil

Fill Cap

S See GUIDE BAR AND CHAIN OIL under

the OPERA TION section.