19

MAINTENANCE

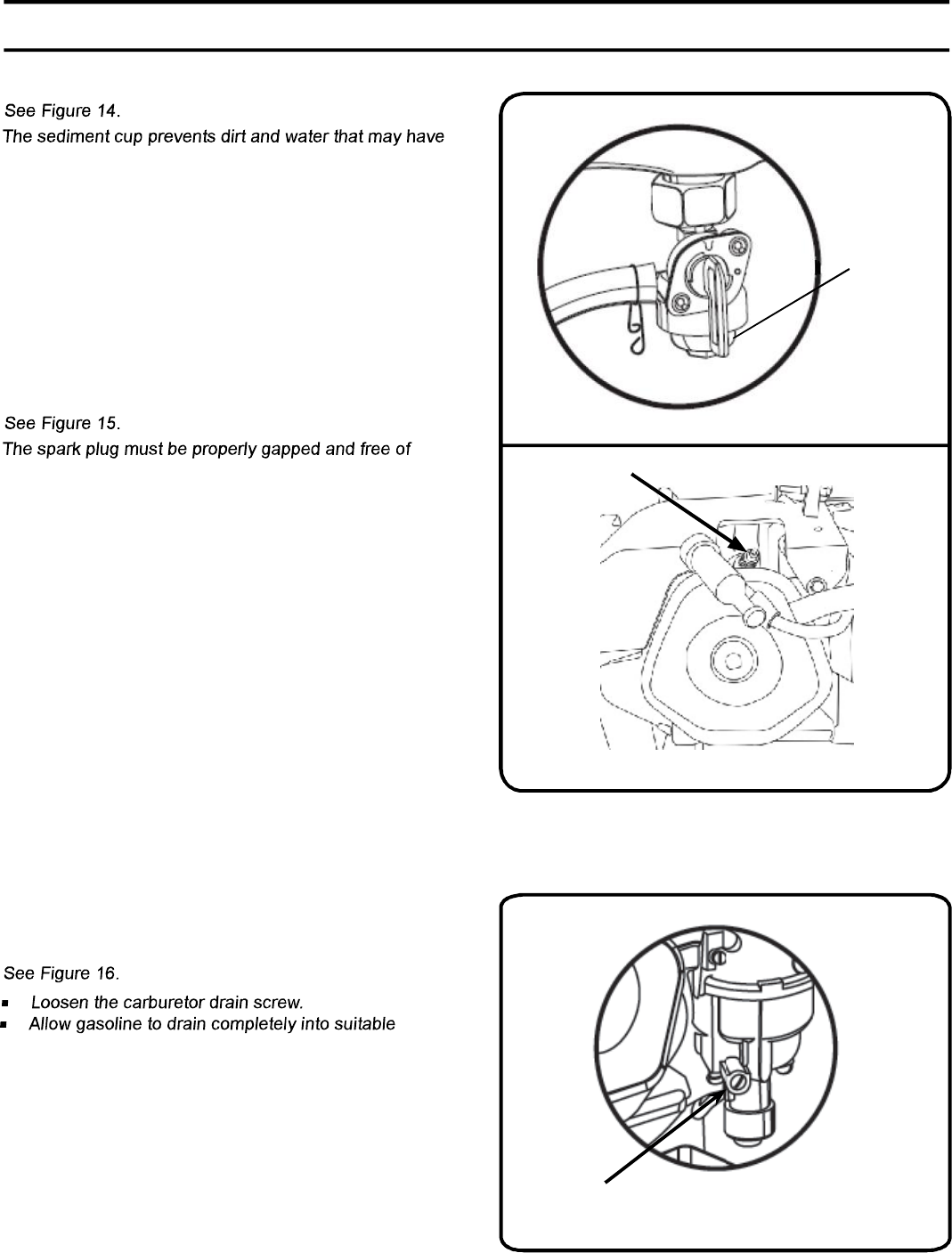

CLEANINGFUELSEDIMENTCUP

gottenintothefueltankfromenteringthecarburetor.If

theenginehasnotbeenrunforalongtime,thesediment

cupshouldbecleanedbeforeuse.

Turnthefuelvalvetotheoffposition.

Removethesedimentcupusinga10mmwrench.

Removetheo-ringandfilter.

Cleaneachofthepartsinahighflash-pointsolvent.

Reinstallthefilter,o-ring,andsedimentcup.Tighten

■

■

■

■

■

with10mmwrenchtosecure.

ReturnthefuelvalvetotheONpositionandcheck■

forleaks.

SPARKPLUGMAINTENANCE

depositsinordertoensureproperengineoperation.

Tocheckthesparkplug:

Removethesparkplugcap.

Cleananydirtfromaroundthebaseofthespark

■

■

plug.

■

■

Removethesparkplug.

Inspectthesparkplugfordamage,andcleanwith

awirebrushbeforereinstalling.Iftheinsulator

iscrackedorchipped,thesparkplugshouldbe

replaced.

NOTE:Ifreplacing,usethefollowingrecommended

sparkplugsorequivalent:NGK,.

Measurethepluggapwithafeelergauge.The

FT7C

■

correctgapis.028-.031in.Correct,ifnecessary,by

carefullybendingthesideelectrode.

Seatsparkpluginposition;threadinbyhandto■

preventcross-threading.

■ Tightenwithsparkplugwrenchtocompresswasher.

Ifsparkplugisnew,use1/2turntocompress

washerappropriateamount.Ifreusingoldspark

plug,use1/8to1/4turnforproperwasher

compression.

Fig.15

Fig.14

SPARKPLUG

SEDIMENT

CUP

DRAININGCARBURETOR

container.

■

■

■

Retightendrainscrew.

TurntheengineswitchandfuelvalveOFF.

TRANSPORTING

Makesureengineandexhaustsystemofunitiscool.

■

■

Keeptheunitleveltopreventfuelspillage.

Donotdroporstriketheunitorplaceunderheavy

objects.

Fig.16

DRAINSCREW