12

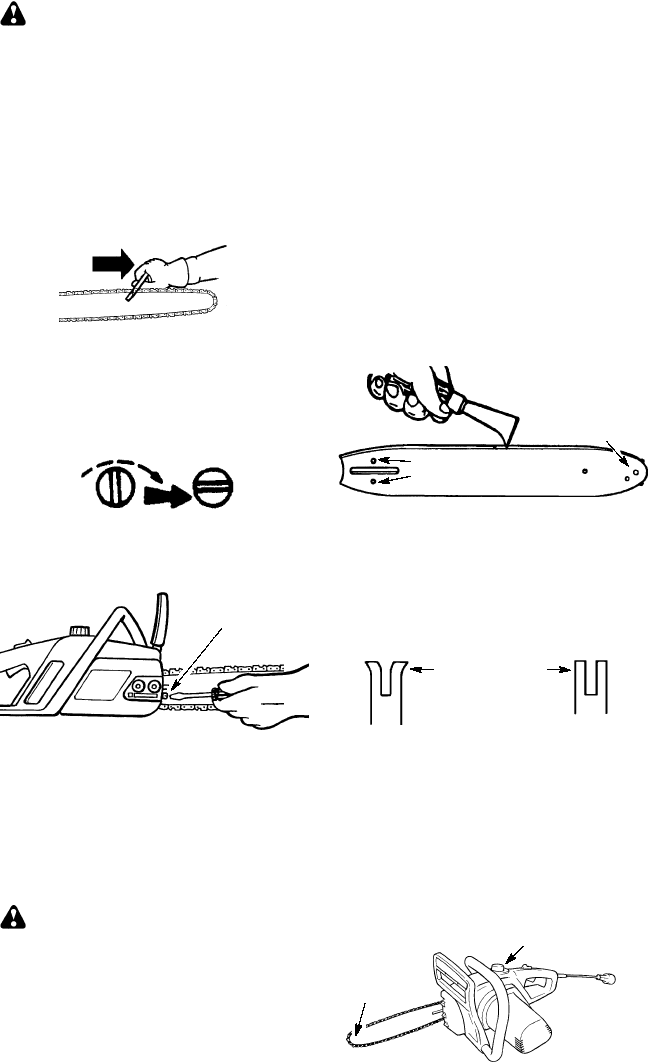

CHECK CHAIN TENSION

WARNING:

Wear protective

gloves when handling chain. The chain

is sharp and can cut you even when it is

not moving.

Chain tension is very important. C hain

stretches during use. This is especially

true during the first few times you use your

saw. Alw ays check chain tension each

time you use your saw .

D

Unplug unit from the pow er source.

D

Use a screwdriver to move chain

around guide bar to ensure k inks do not

exist. The chain should rotate freely.

D

Loosen bar clamp nuts until they are

finger tight against the bar clamp.

D

T urn the adjusting screw clockwise until

the chain solidly contacts bottom of

guide bar rail. Then, turn adjusting

screw an additional 1/4 turn.

Adjusting Screw -- 1/4 Turn

NOTE: To tighten the chain, turn the ad-

justing screw clockwise; to loosen the

chain, turn the adjusting screw counter-

clockwise.

Adjusting Screw

D

Check the tension by lifting the chain

from the guide bar . Rem ove som e of the

stiffness in the chain by pulling down

and letting go of the chain several times.

D

Continue turning the adjusting screw

until the tension is correct.

D

T ighten bar mounting nuts with a

wrench.

D

Recheck chain tension.

WARNING:

If the saw is operated

with a loose chain, the chain could jump

off the guide bar and result in serious in-

jury.

CHECK CHAIN SHARPNESS

A sharp chain makes wood chips. Adull

chain makes a sawdust powder and

cuts slowly. See

CHAIN SHARPENING

in

the

SERVICE AND ADJUSTMENTS

section.

CHECK GUIDE BAR

Conditions which require guide bar main-

tenance:

S

Saw cuts to one side or at an angle.

S

Saw has to be forced through the cut.

S

Inadequate supply of oil to the bar and

chain.

Check the condition of the guide bar each

time the chain is s harpened. A worn guide

bar will damage the chain and make cut-

ting difficult.

After each use, w ith unit disconnected

from power source, clean all sawdust from

the guide bar and sprocket hole.

To maintain guide bar:

S

Disconnect the chain saw from the

power source.

S

Loosen and remove bar m ounting nuts.

Remove bar and chain from saw .

S

Clean the oil holes and bar groove af-

ter each 5 hours of operation.

Remove Sawdust From

Guide Bar Groove

Sprocket Hole

Oil Holes

S

Add lubricant to sprocket hole after

each use.

S

Burring of guide bar rails is a normal

process of rail wear. Remove these

burrs with a flat file.

S

When rail top is uneven, use a flat file

to restore square edges and sides.

Correct GrooveWorn Groove

File Rail Edges

and Sides

Square

Replace the guide bar w hen the groove is

worn, the guide bar is bent or crack--ed, or

when excess heating or burring of the rails

occurs. If replacement is necessary, u se

only the guide bar specified for your sawin

the repair parts list or on the decal located

on the chain saw.

LUBRICATION

Bar

Sprocket

Bar Oil

Fill Cap