15

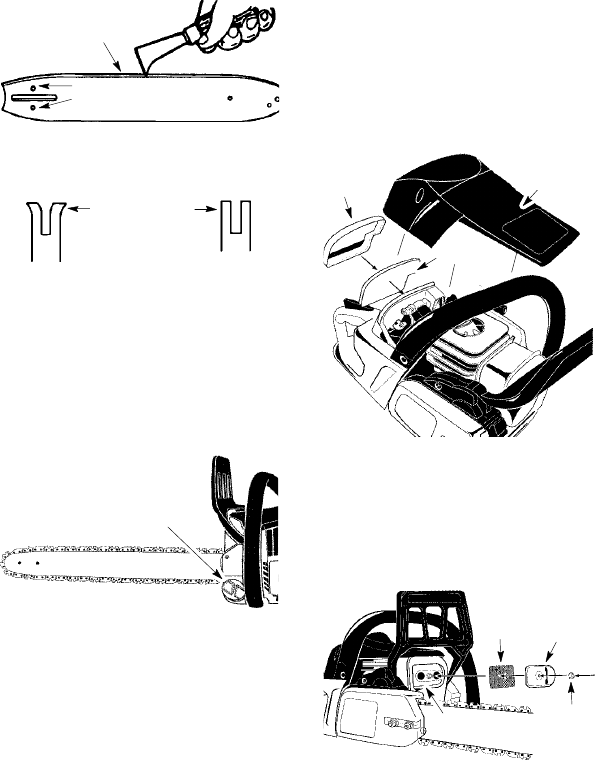

S Clean the oil holes and bar groove after

each 5 hours of operation.

Remove Sawdust From

Guide Bar Groove

Oil Holes

S Burring of guide bar rails is a normal

process o f rail wear . Remove these burrs

with a flat file.

S Whenrailtopisuneven,useaflatfiletore-

store square edges and sides.

Correct GrooveWorn Groove

File Rail Edges

and Sides

Square

Replace guide bar when the groove i s worn,

the guide bar is bent or cracked, or w hen ex-

cess heatingor burringof therails occurs.Ifre-

placementis necessary,useonlytheguidebar

specified for your saw in the repair parts list or

on the decal located on the chain saw.

CHECK FUEL MIXTURE LEVEL

S See FUELING ENGINE under the OP-

ERA TION section.

LUBRICATION

Bar Oil

Fill Cap

S See GUIDE BAR AND CHAIN OIL under

the OPERATION section.

INSPECT AND CLEAN UNIT AND

DECALS

S After each use, inspect complete unit for

loose or damaged parts. Clean the unit and

decals using a damp cloth with a milddeter-

gent.

S Wipe off unit with a clean dry cloth.

CHECK CHAIN BRAKE

See CHAIN BRAKE in the OPERATION

section.

CLEAN AIR FILTER

CAUTION:

Donotcleanfilteringasolineor

other flammable solvent to avoid creating a

firehazardo rp roducingharmfulevaporative

emissions.

Cleaning the air filter:

Adirtyair filterdecreases thelifeand perfor-

mance oftheengineandincreases fuelcon-

sumption and harmful emissions. Always

clean your air filter after 10 tanks of fuelor 5

hours of oper ation, whichever comes first.

Cleanmorefrequently industy conditions.A

used air filter can never be completely

cleaned. Itis advisable toreplaceyour airfil-

terwithanewoneafterevery 50hoursofop-

eration, or annu ally, whichever comes first.

1. Loosen 3 screws on cylinder cover.

2. Remove cylinder cover .

3. Remove air filter cover and air filter.

4. Cleantheairfilterusinghotsoapywater.

Rinsewithcleancoolwater.Airdrycom-

pletely before reinstalling.

5. Reinstall air filter and air filter cover.

6. Reinstall c ylinder c over and 3 screws.

Tighten securely.

Air Filter

Cover

Cylinder

Cover

Air Filter

INSPECT MUFFLER AND SPARK

ARRESTING SCREEN

As theunit isused, carbondeposits buildup

on t he muffler and spark arresting screen,

andmustberemovedtoavoidcreatingafire

hazard or affecting engine performance.

Replacethespark arrestingscreenifbreaks

occur.

Nut

Exhaust

Outlet

Cover

Muffler

Spark

Arresting

Screen

CLEANING THE SPARK ARREST -

ING SCREEN

Cleaning is required every 25 hours of op-

eration or annually, whichever comes first.

1. Loosenandremovethenut fromtheex-

haust outlet cover.

2. Remove the exhaust oulet cover.

3. Removesparkarrestingscreen.Handle

screen carefully to prevent damage.

4. Cleanthespark arresting screen gently

with a wire brush. Replace screen if

breaks are found.

5. Replace any broken or cracked muffler

parts.

6. Reinstall spark arresting screen, exhaust

outlet cover ,and nut.Tighten nutsecurely .