17

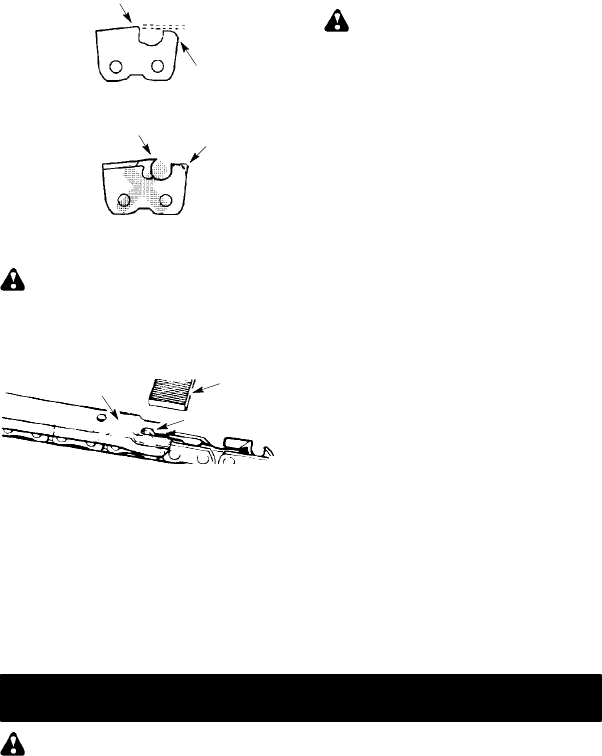

Rounded

Corner

0.025 inch

(0.65mm)

Right

Hook Angle

Wrong

Squared O

f

f

Corner

Too Much Hook

A

ngle

WARNING: Maintain the proper

hook angle according to the manufacturer’s

specifications for the chain you are using. Im-

proper hook angle will increase the chance of

kickback which can result in serious injury .

4. Check and lower depth gauges.

Depth Gauge Tool

Depth Gauge

File

S Place gauge tool on cutter.

S If the dep th gau ge i s higher than the

depthgaugetool,fileitleveltothetopof

the depth gauge tool.

S Maintain rounded front corner of

depth gauge with a flat file.

NOTE: The very top of the depth

gauge should be flat with the front

half rounded off with a flat file.

If you require further a ssistance or are unsure

about performing this procedure, contact your

authorized service dealer or call our customer

assistance help line at 1--800--554--6723.

CARBURETOR ADJUSTMENT

WARNING: Thechainwillbemoving

during most of this procedure. Wear your pro-

tective equipment and observe all safety pre-

cautions. The chain must not move at idle

speed.

The carburetor has been carefully set at the

factory. Adjustments may be necessary if

you notice any of the following conditions:

S Chainmoves at idle.See IDLESPEED--T

adjusting procedure.

S Saw willnot idle.SeeIDLESPEED--T ad-

justing procedure.

Idle Speed--T

Allow engine to idle. If the chain moves, idle is

toofast. Iftheenginestalls,idleistooslow . Ad-

just speed until engine runs without chain

movement (idle too fast) or stalling (idle too

slow). The idle speed screw i s located in the

area above the primer bulb and is labeled T.

S Turn idle screw (T) clockwise to increase

engine speed.

S Turn idle screw (T) counterclockwise to

decrease engine speed.

If you require further a ssistance or are unsure

about performing this procedure, contact your

authorized service dealer or call our customer

assistance help line at 1--800--554--6723.

COOLING SYSTEM

To keep the working temperature as low as

possible the machine is equipped with a

cooling system.

The cooling system consists of:

S Air intake on the starter

S Air guide plate

S Fins on the flywheel

S Cooling fins on the cylinder

S Cylinder cover (directs cold air ov er the

cylinder)

Clean the cooling system with a brush after

each use, more often in demanding condi-

tions. A dirty or blocked cooling system re-

sults i n the machine overheating which

causes damage to the piston and cylinder.

STORAGE

WARNING: Perform the following

steps after each use:

S Allow the engine to cool, and secure the

unit before storing or transporting.

S Store chain saw and fuel in a well venti-

latedarea wherefuelvaporscannotreach

sparksoropenflamesfromwaterheaters,

electric motors orswitches, furnaces,etc.

S Store chain saw with all guards in place

and position chain saw so that any sharp

object cannot accidentally cause injury.

S Store chain saw well out of the r each of

children.

SEASONAL STORAGE

Prepareyourunitforstorageattheendofthe

season orif it will not beusedfor 30 days or

more. If your chain saw is to be stored for a

period of time:

S Clean saw thoroughly before storage.

S Store in a clean dry area.

S Lightly oil external m etal surfaces and

guide bar.

S Oilthechainand wrapit inheavy paperor

cloth.

FUEL SYSTEM

Under FUELING ENGINE in the OPERA-

TION s ection of this manual, see message

labeled IMPORTANT r egarding the u se of

gasohol inyour chain saw. Fuel stabilizer is

an acceptable alternative in minimizing the

formation of fuel gum deposits during stor-

age. Addstabilizer tothe gasolinein thefuel

tankorfuelstoragecontainer.Followthemix

instructions found on s tabilizer containers.

Run engine at least 5 minutes after adding

stabilizer. Poulan/WEED EATER 40:1,

2-cycleengineoil(aircooled)isblendedwith

fuel stabilizer. If you do not use this oil, you

can add a fuel stabilizer to your fuel tank.