15

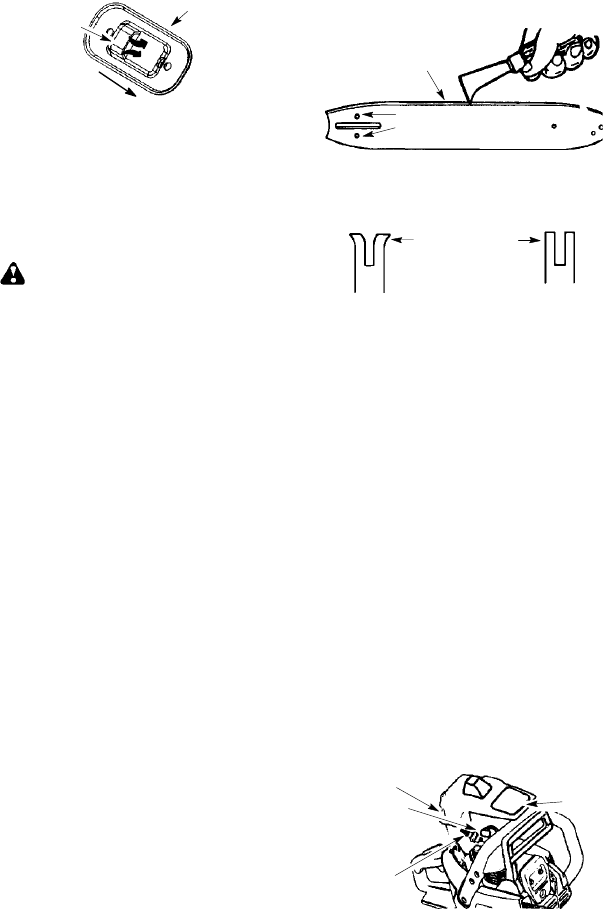

Exhaust Outlet must face chain

brake ( bar side) of chain saw

Outlet Co

v

er

Exhaust

Outlet

10. Inspect the muf fler gasket and r eplace if

damaged.

11. Reinstall backplate, outlet guide,muffler

gasket, and muffler using muffler bolts.

Tighten until secure.

12. Reinstall bo ltcover andlocknut. Tighten

securely.

CARBURETOR ADJUSTMENT

WARNING: The chain will be mov-

ing during most of thisprocedure. Wearyour

protective equipment and observe all safety

precautions. Thechain m ustnotmove atidle

speed.

The carburetor has been carefully set at the

factory. Adjustments may be necessary if

you notice any of the following conditions:

S Chain moves a t idle. See IDLE SPEED--T

adjusting procedure.

S Saw will not idle. S eeIDLE SPEED--T ad-

justing procedure.

Idle Speed--T

Allow engine to idle. If t he chain moves, idle

istoofast. Iftheenginestalls,idleis tooslow.

Adjust speed until engine r uns without chain

movement (idle too fast) or stalling (idle too

slow). The idlespeed screw is locatedin the

area above the primer bulb and is labeled T.

S Turn idle speed screw (T) clockwise to in-

crease engine speed.

S Turn idle speed screw ( T) counterclock-

wise to decrease engine speed.

If you require further assistance or are unsure

about performing this procedure, contact your

authorized service dealer or call

1--800--554--6723.

BAR MAINTENANCE

If your saw cuts to oneside, has tobe forced

through thecut, o rbeenrunwithanimproper

amount of bar lubrication it may be neces-

sarytoserviceyourbar . Awornbar willdam -

age your chain and make cutting difficult.

After each use, ensure ON/STOP switch is

in the S TOP position, thenclean allsawdust

from the guide bar and sprocket hole.

To m aintain guide bar:

S Move ON/STOP switch to the STOP posi-

tion.

S Loosen and remove chain brake nuts and

chain brake. Remove bar and chain from

saw.

S Clean the oil holes and bar groove after

each 5 hours of operation.

Remove Sawdust From

Guide Bar Groove

Oil Holes

S Burring of guide bar rails is a normal

process of r ail wear. Remove t hese burrs

with a flat file.

S When railtopis uneven, useaflat filetore-

store square edges and sides.

Correct GrooveWorn Groove

File Rail Edges

and Sides

Square

Replace guide bar when the groove is worn,

the guide bar i s bent or cracked, orwhen exce-

ss heating or burring of the rails occurs. If re-

placement is necessary, u se only the guidebar

specified f or your saw i n t he repair parts list or

on the decal located on the chain saw.

CHAIN SHARPENING

Chain sharpening is a complicated task that

requires special tools. We recommended

you refer chain sharpening to a p rofessional

chain sharpener .

IGNITION TIMING

Ignition tim ing is fixed and nonadjustable.

SPARK PLUG

The spark plug should be replaced each

year to ensure the engine starts easier and

runs better.

1. Loosen 3 screws on cylinder cover.

2. Remove the cylinder cover.

3. Pull off the spark plug boot.

4. Remove spark plug from cylinder and

discard.

5. Replace with Champion RCJ--7Y spark

plug andtighten securely with a 3/4 inch

(19 mm) socket wrench. Spark plug gap

should be 0.025 inch (0.6 mm).

6. Reinstall the spark plug boot.

7. Reinstall the cylinder cover and 3

screws. Tighten securely.

Screws

Spark

Plug Boot

Spark

Plug

Cylinder

Cover