9

OPERATING INSTRUCTIONS FOR

USE WITH BRUSH BLADE

S

Blade Thrust i s a r eaction that only occurs

when using a bladed uni t. This r eaction can

cause serious injury such as amputation.

Carefully study this section. It is impor tant that

you understand w hat causes bl ade thrust,

how you can reduce the chance of its occur-

ring, and howyou can remain in control of unit

if blade thrust occurs .

S

WHA T CAUSES BLADE THRUST -- Blade

Thrust can occur when the s pinning blade

contacts an object that it does not cut. This

contact causes the bladeto stop for aninstant

and then suddenly move or “thrust” awayfrom

the object that washit. The “thrusting” reaction

can be violent enoughtocause the operatorto

be propelled in any direction and lose control

of the unit. The uncontrolled uni t can cause

seriousinjuryiftheblade contacts theoperator

or others.

S

WHEN BLADE THRUST OCCURS --

Blade Thrust can occur without warning if

the blade s nags, stalls, or binds. This is

more likely to occur in a reas where it is d iffi-

cult to see the material being cut. By using

the unit properly, the occurrence of blade

thrust wi ll be reduced and the operator will

be less likely to lose control.

S

Cut only grass, weeds, and woody brush up

to 2 inches i ndiameter with the brush blade.

Do not let the blade contact material it can-

not cut such as stumps, rocks, fences,

metal, etc., orclusters of hard, woody brush

having a diameter greater than 2 inches.

S

Keep the blade sharp. A dull blade is more

likely to snag and thrust.

S

Cut only at full throttle. The blade will have

maximum cutting power and is less likely to

bind or stall.

S

“Feed” the blade deliberately and not t oo

rapidly. The blade can thrust away if it is fed

too rapidly.

S

Cut only from your right to your left. Swing-

ing the unit in the same direction as the

blade spins increases the cutting action.

S

Use the shoulder strap and keep a firm grip

on the unit with both hands. A properly ad-

justed shoulder strap w ill support the weight

of the unit, freeing your arms and hands to

control and guide the cutting motion.

S

Keep feet comfortably spread apart and

braced for a possible sudden, rapid thrust of

unit. Do not over r each. Keep firm footing and

balance.

S

Keep blade below waist level; it will be eas-

ier to maintain control of unit.

S

Do not raise the engine above your waist as

the blade can come dangerously close to

your body.

S

Do not swing unit with such force that you

are in danger of losing your balance.

Bring the engine to cutting speed before enter-

ing the material to be cut.

If the blade does not turn when you squeeze

the throttle trigger, make sure tube is fully in-

serted into the engine.

Always release the throttle trigger and allow

engine toreturn toidle speedwhen notcutting.

The blade should not turn while the engine is

running at idle. If the blade turns at idle, do not

use your unit. Refer to the Carburetor adjust-

ment section or contact your Authorized Ser-

vice Dealer.

S

Maintain good firm footing while using the

unit. Dothis by planting feet firmly in a com-

fortable apart position.

S

Cut while swinging the upper part of your

body from ri ght to left.

S

As you move forward to the next area to cut,

be sure to maintain your balance and foot-

ing.

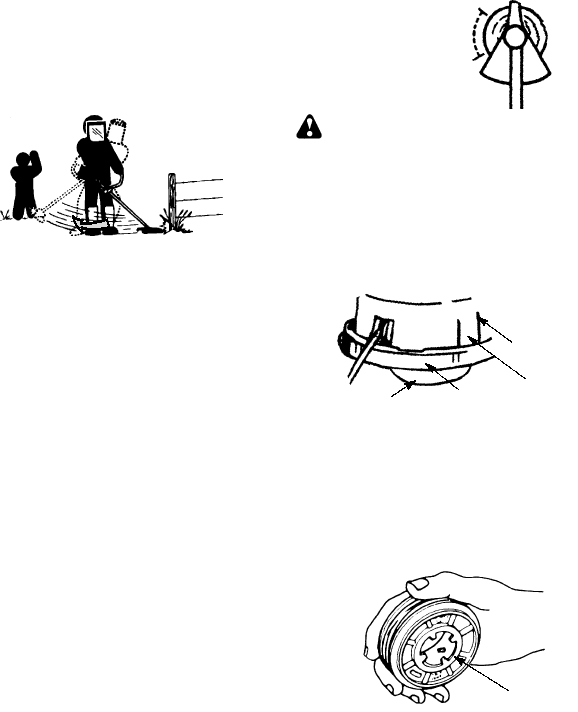

Cut using the 8 o’clock

to 10 o’clock position of

the blade

10 o’clock

8 o’clock

WARNING:

The operator or others

must not try to clear away cut material with the

engine running or the blade turning to avoid

serious injury. Stop engine and blade before

removing materials wrapped around blade or

tube.

REPLACING THE LINE

S

Press the tab on the side of the trimmer

head and twist the lock ring.

S

Remove the lock r ing and tap button.

Tab

Lock Rin

g

Tap Button

Trimmer

Head

S

Pull spool out of the trimmer head.

S

Clean dirt and debri s from all parts.

S

Replace with apre-wound spool ,or replace

line using two 20 foot lengths of 0.080” (2

mm) diameter line.

S

When installing new line on a n existing spool,

insert 1/16

I

of the line into the anchoring hole

in the bed of the spool, and wrapthe line even-

ly and and firmly ar oundthe spool in thedirec-

tion of the ar row found on the spool.

Anchoring

Hole

S

Insert ends of the lines through the exit holes

in the sides of the tr immer head.