6

Computed kic kback angle (CKA) Table

BAR

P/N

Length

CHAIN P/N

952044370

14!

952051211

MODEL

952044418

16!

952051338

14

_

CKA without chain brake

2250

2250/2450

19

_

2550

18!

952044368 952051209

24

_

NOTE:

If this saw is to b e used for commer-

cial logging, achain brake isrequired and shall

not be removed or otherwise disabled to com-

ply with Federal OSHA Regulations for Com-

mercial Logging.

SAFETY NOTICE:

Exposure to v ibrations

through prolonged use of gasoline powered

hand tools could c ause blood vessel or nerve

damage in the fingers, hands, and joints of

people prone to circulation disor ders or

abnormal swellings. Prolonged us e in cold

weather has been linked to blood vessel

damage in otherw ise healthy people. If

symptoms occur such a s numbness, pain,

loss ofstrength, changein skincolorortexture,

or loss of feeling in the fingers, hands, orjoints,

discontinue the use of this tool and seek

medical attention. An anti-vibration system

does not guarantee the avoidance of these

problems. Users w ho operate power tools on

a continual and regular basis must monitor

closely their physical condition and the

condition of this tool.

SPECIALNOTICE:

Yoursaw isequipped

with atemperature limiting muffler and spark

arresting screen which meets the

requirements of California Codes 4442 and

4443. All U.S. forest land and the states of

California, Idaho, Maine, Minnesota, New

Jersey, Oregon, and Washington require by

law that many internal c ombustion engines

tobeequipped with aspark arresting screen.

If you operate a chain sawin astate orlocale

where such regulations exist, you are legally

responsible for maintaining the operating

condition of these parts. Failure to do so is

a violation of the law. Refer to the SERVICE

section for maintenance of the spark

arresting screen.

Failure tofollowall Safety Rules andPrecau-

tions can result in serious i njury. If situations

occur which are not covered in this manual,

use care and good j udgement. If you need

assistance, contact your authorized service

dealer or call 1-800--554--6723.

STANDARDS:

This sawis listed byUnder-

wr iter’s Laboratories, I nc., and the Canadian

Standards Association in accordance w ith:

ANSI B175.1-2000 American National

Standard for Powered Tools -- Gasoline

Powered Chain Saw -- Safety Requi rements

CSA Z62.1--1995 Chain Saws -- Occupa-

tional Health and Safety

CSA Z62.3--1996 Chain Saw Kickback Oc-

cupational Health and Safety

ASSEMBLY

Protective gloves (not provided) should be

worn during assembly.

ATTACHINGTHEBAR&CHAIN

(If not

already attached)

WARNING:

If received assembled,

repeat all steps to ensure your saw is prop-

erly assembled and all fasteners are secure.

Always wear gloves when handl ing the

chain. The chain is sharp and can cut you

even when it is not moving!

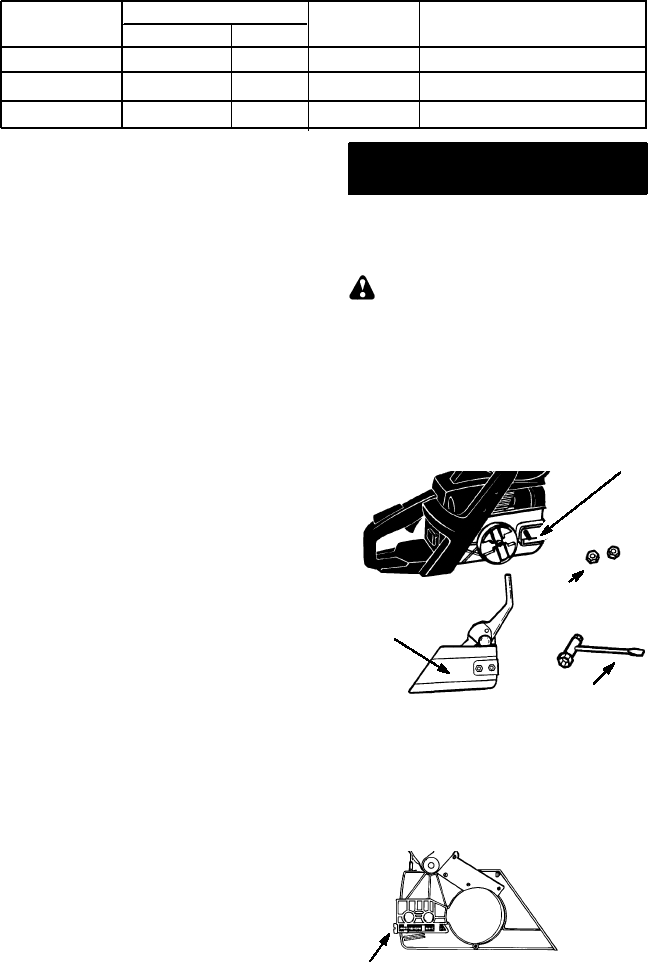

1. Loosen andremove the chain brakenuts

and the chain brake from the saw.

2. Remove the plastic shipping spacer (if

present).

Chain Brake

Chain Brake

Nuts

Bar Tool

Location of shipping spacer

3. An adjusting pin and scr ew is used to ad-

just the tension of the chain. It is very i m-

portant when assembling the bar, that the

pin located on the adjusting screw aligns

into ahole in the bar. Tur ningthe screwwill

move the adj ustment pin up and dow n the

screw. Locate this adjustment before you

begin mounting the bar onto t he saw. See

illustr atio n below.

Adjustment located on Chain Brake

Inside view of

Chain Brake

4. Turn the adjusting screw by hand coun-

terclockwise until the adjusting pin just

touches the stop. This should allow the

pin to be near the correct position.

5. Slide guide bar behind clutch drum until

guide bar stops against clutch drum

sprocket.