17

SERVICE AND ADJUSTMENTS

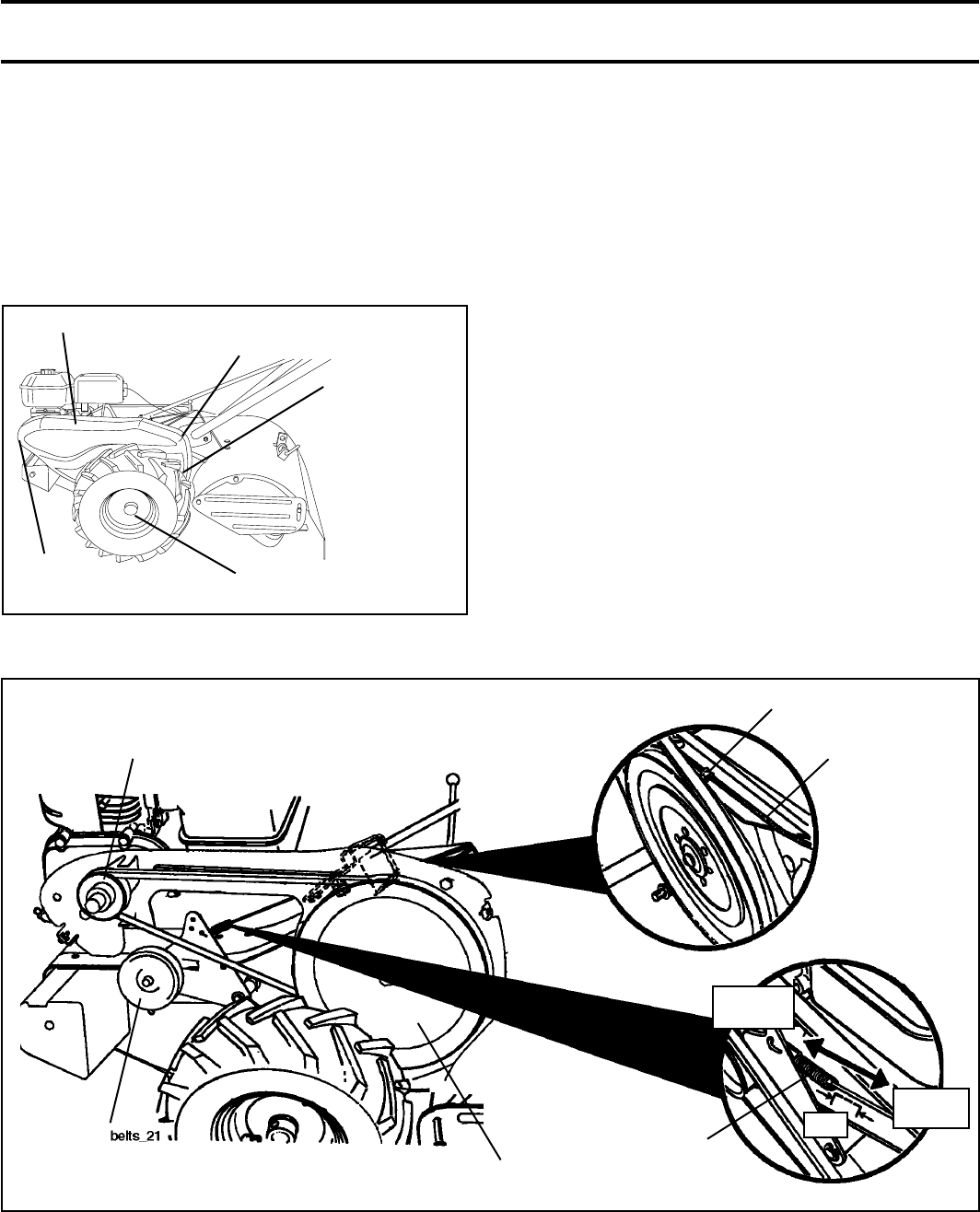

TO REPLACE GROUND DRIVE BELT

(See Figs. 27 and 28)

• Remove belt guard as described in “TO REMOVE BELT

GUARD”.

• Remove old belt by slipping off engine pulley fi rst then

remove from transmission pulley.

• Place new belt in groove of transmission pulley and

into engine pulley. BELT MUST BE IN GROOVE ON

TOP OF IDLER PULLEY. NOTE POSITION OF BELT

TO GUIDES.

• Check belt adjustment as described below.

• Replace belt guard.

• Reposition wheel and replace clevis pin and hairpin

clip.

GROUND DRIVE BELT ADJUSTMENT

(See Fig. 28)

For proper belt tension, the extension spring should have

about 5/8 inch (16 mm) stretch when drive control bar is

in “EN GAGED” position. This tension can be attained as

follows:

• Loosen cable clip screw securing the drive control

cable.

• Slide cable forward for less tension and rearward for

more tension until about 5/8 inch (16 mm) stretch is

obtained while the drive control bar is engaged.

• Tighten cable clip screw securely.

LESS

TEN SION

ENGINE

PULLEY

IDLER

PULLEY

TRANS MIS SION

PULLEY

CABLE CLIP

SCREW

DRIVE

CONTROL

CABLE

MORE

TEN SION

5/8"

EXTENSION

SPRING

TO REMOVE BELT GUARD

(See Fig. 27)

NOTE: For ease of removal, remove hairpin clip and clevis

pin from left wheel. Pull wheel out from tiller about 1 inch

(2.5 cm).

• Remove two (2) screws from side of belt guard.

• Remove hex nut and washer from bottom of belt guard

(located behind wheel).

• Pull belt guard out and away from unit.

• Replace belt guard by reversing above procedure.

BELT GUARD

SCREW

HAIRPIN CLIP AND

CLEVIS PIN

HEX NUT

AND WASHER

(LOCATED BEHIND

TIRE)

FIG. 27

FIG. 28

SCREW