22

SERVICE AND ADJUSTMENTS

FIG. 26

L.H.

MANDREL

CENTER MANDREL

IDLER

PULLEY

R.H. MANDREL COVER

SPRING

FIG. 25

TO REPLACE MOTION DRIVE BELT

(See Fig. 27)

Park the tractor on level surface. Engage parking brake. For

assistance, there is a belt installation guide decal on bottom

side of left footrest.

• Remove mower (See “TO REMOVE MOWER” in this

section of this manual.)

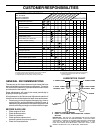

TO REPLACE MOWER BLADE DRIVE BELT

(See Fig. 25)

Park the tractor on level surface. Engage parking brake.

• Remove mower drive belt (See “TO REPLACE MOWER

DRIVE BELT” in this section of this manual).

• Remove mower (See “TO REMOVE MOWER” in this

section of this manual).

• Remove screws from L.H. mandrel cover and remove

cover.

• Carefully roll belt off L.H. mandrel pulley.

• Remove belt from center mandrel pulley, idler pulley,

and R.H. mandrel pulley.

• Remove any dirt or grass which may have accumulated

around mandrels and entire upper deck surface.

• Check secondary idler arm and idler pulley to see that

they rotate freely.

• Be sure spring is hooked in secondary idler arm and

secondary spring arm.

• Install new belt in lower groove of R.H. mandrel pulley,

idler pulley, and center mandrel pulley as shown.

• Carefully roll belt over L.H. mandrel pulley. Make sure

belt is in all grooves properly.

• Reinstall L.H. mandrel cover.

• Reinstall mower to tractor (See “INSTALL MOWER AND

DRIVE BELT” in the Assembly section of this manual).

• Reassemble mower drive belt (See “TO REPLACE

MOWER DRIVE BELT” in this section of this manual).

SECONDARY

IDLER ARM

SECONDARY

SPRING ARM

FIG. 24

• Carefully check belt routing making sure belt is in the

grooves correctly.

• Reconnect R.H. suspension arm to rear deck bracket

with retainer spring.

• Reassemble R.H. mandrel cover.

• Engage belt tension rod by pushing rod into locking

bracket.

PRIMARY

IDLER ARM

R.H.

MANDREL

IDLER

PULLEY

ELECTRIC

CLUTCH

PULLEY

SPRING

ARM

BELT

TENSION ROD

(DISENGAGED

POSITION)

RH MANDREL

COVER

RH

SUSPENSION

ARM

IDLER

PULLEY

WITH PARKING BRAKE “ENGAGED”

JAM NUT

DO NOT TOUCH THIS NUT. IF FURTHER BRAKE

ADJUSTMENT IS NECESSARY CONTACT YOUR NEAREST

AUTHORIZED SERVICE CENTER/DEPARTMENT

OPERATING

ARM

NUT “A”

1-3/4"

TO ADJUST BRAKE (See Fig. 26)

Your tractor is equipped with an adjustable brake system

which is mounted on the side of the transaxle.

If tractor requires more than six (6) feet stopping distance at

high speed in highest gear on a level dry concrete or paved

surface, then brake must be adjusted.

• Depress clutch/brake pedal and engage parking brake.

• Measure distance between brake operating arm and nut

“A” on brake rod.

• If distance is other than 1-3/4", loosen jam nut and turn

nut “A” until distance becomes 1-3/4". Retighten jam nut

against nut “A”.

• Road test tractor for proper stopping distance as stated

above. Readjust if necessary. If stopping distance is

still greater than six (6) feet in highest gear, further

maintenance is necessary. Contact your nearest au-

thorized service center/department.