12

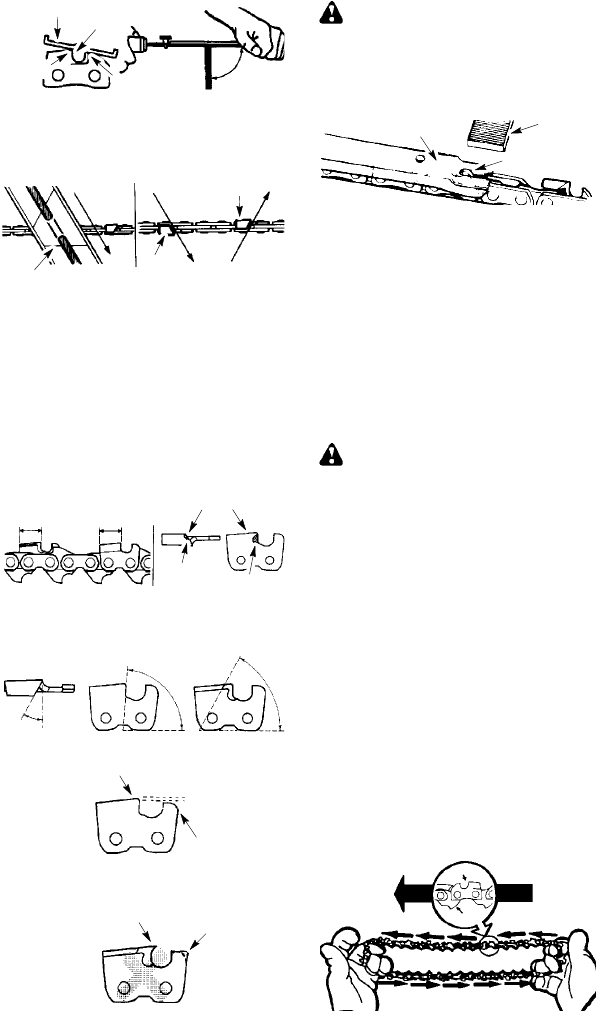

Depth Gauge

File

File Holder

Cutter

90˚

S Alignthe30˚ fileholdermarks p arallel

with the bar and to the center of the

chain.

Cutter

Cutter

30˚

File Holder Line

S Sharpencuttersononesideofthechain

first. Filefromtheinside o feach cutterto

the outside. Then, turn the chain saw

around and repeat the process for the

other side of the chain.

S Fileon the forward stroke only. Use 2

or 3 strokes per cutting edge.

S Keepallcutters thesamelengthwhen

filing.

S Fileenoughtoremoveany damageto

cuttingedges(side plateand topplate

of cutter).

A

ll Cutters

Same Length

Remo

v

e Damage

Top Plate

Side Plate

S File chain to meet the specifications

as shown.

30˚

75˚

60˚

Rounded

Corner

0.025 inch

(0.65mm)

Right

Hook Angle

Wrong

Squared O

f

f

Corner

Too Much Hook

A

ngle

WARNING: Maintain the proper hook

angleaccordingtothemanufacturer’sspecifica-

tions forthe chainyou areusing. Improperhook

angle will increase the chance of kickback

which can result in serious injury.

4. Check and lower depth gauges.

Depth Gauge Tool

Depth Gauge

File

S Place gauge tool on cutter.

S If the depth gauge is higher than the

depth gauge tool,file itlevel tothe topof

the depth gauge tool.

S Maintainroundedfrontcornerofdepth

gauge with a flat file.

NOTE: The very top of the depth

gaugeshouldbeflat withthe fronthalf

rounded off with a flat file .

If you require further assistance or are unsure

about performing this procedure, contact your

authorized service dealer or call our customer

assistance help line at 1--800--554--6723.

CHAIN REPL ACEMENT

WARNING: Wear protective gloves

when handling chain. Thechain is sharp and

can cut you even when it is not moving.

It is normal for anew chain to stretch duringthe

first 15 minutes of operation. Y ou should re-

check your chain tension frequently and adjust

thechain tensionas required.See CHAINTEN-

SION section.Replacethe oldchainwhenitbe-

comes worn or damaged. Use only the Low-

Kickback replacement chain specified in the

repair parts list.

TO REPLACE CHAIN:

1. MoveON/STOPswitchtotheSTOPposi-

tionanddisconnectsparkplug(ordiscon-

nect powerhead from power source).

2. Remove bar clamp nut.

3. Remove bar clamp.

4. Turn adjusting screw by hand counter-

clockwise until adjusting pin just touches

the stop.

5. Slide guide bar behind sprocket until

guide bar stops against sprocket.

6. Remove the old chain.

7. Carefully remove new chain from pack-

age. Hold chain with the drive links as

shown.

CUTTERS MUST FACE IN

DIRECTION OF R OTATION

Tip of

Bar

Cutter

Drivelink