12- ENG

A07513

MAINTENANCE

When performing

maintenance, you

may be exposed to hot surfaces,

water pressure, or moving parts

that can cause serious injury or

death!

Before performing any maintenance

or repair, disconnect spark plug

wire, let engine cool and release

all water pressure. The engine

contains flammable fuel. DO NOT

smoke or work near open flames

while performing maintenance.

To ensure efficient operation and

longer life of your pressure washer,

a routine maintenance schedule

should be prepared and followed.

If the pressure washer is used in

unusual conditions, such as high-

temperatures or dusty conditions,

more frequent maintenance checks

will be required.

ENGINE

Consult the Engine Owners

Manual for the manufacturer's

recommendations for any and all

maintenance. NOTE: The frame is

equipped with an oil drain hole to help

make changing the engine oil easier.

PUMP

The oil in the high pressure pump was

designed to last the life of the pump.

If there is a problem with the pump

contact an Authorized Service Center.

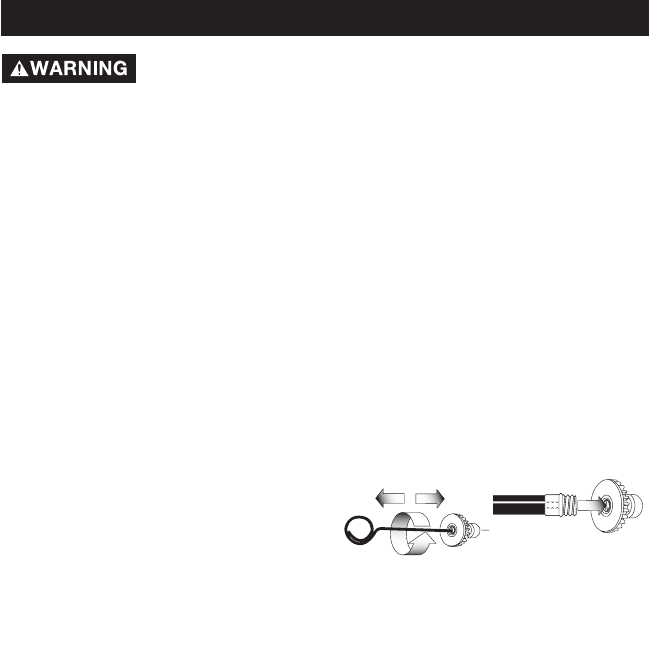

NOZZLE CLEANING

If the nozzle becomes clogged

with foreign materials, such as dirt,

excessive pressure may develop. If

the nozzle becomes partially clogged

or restricted, the pump pressure will

pulsate. Clean the nozzle immediately

using the nozzle kit supplied and the

following instructions:

1. Shut off the pressure washer and

turn off the water supply.

2. Pull trigger on gun handle to

relieve any water pressure.

3. Disconnect the spray wand from

the gun.

4. Remove the high-pressure nozzle

from the spray wand. Remove

any obstructions with the nozzle

cleaning tool provided and

backflush with

clean water.

5. Direct water supply into spray

wand to backflush loosened

particles for 30 seconds.

6. Reassemble the nozzle to the

wand.

7. Reconnect spray wand to gun

and turn on water supply.

8. Start pressure washer and place

spray wand into high pressure

setting to test.