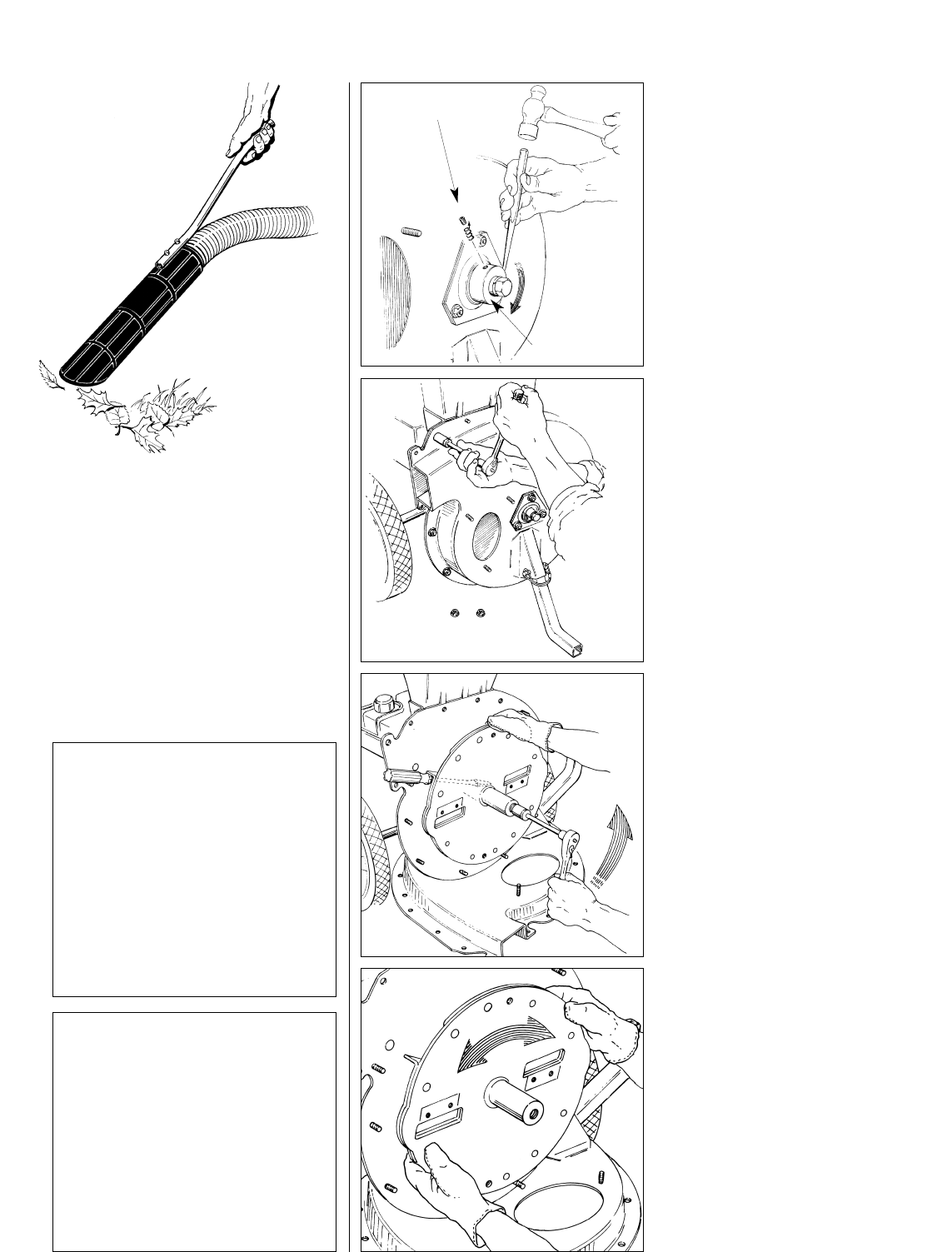

3

Loosen the lock collar by unscrewing

and removing the set screw with an

1/8” Allen wrench. Insert a pin

punch and tap at an angle with a ball

peen hammer, turning the collar

clockwise until you can remove it.

(Before reassembling the collar, use

sand paper to smooth the burr where

the set screw enters the hub. Be sure

the collar mounts flush with the out-

side of the rotor bearing shaft.)

4

Remove the flange nuts from around

the perimeter of the fan housing.

Next, loosen but do not remove the

three flange nuts holding the triangu-

lar flangettes over the bearing. Pull

apart the housings, then take off the

flangettes and remove the entire fan

housing. Position it underneath the

unit, as seen in the next drawing...

5

Note how the fan housing has been

placed underneath. Put a rag there,

too, to avoid scratching the housing.

Use a 9/16” wrench to remove the

3/8” bolt from the center of the rotor

shaft. (When reassembling, use a

torque wrench to tighten this bolt to

45 ft.-lbs.)

6

Pull the rotor from the crankshaft by

turning the rotor back and forth.

There may be some resistance. Pull it

off steadily, making sure that the

hammers clear the inner wall of the

center plate. (When reassembling,

coat the exposed engine shaft and

key with a liquid graphite or slip

plate type compound.)

THE VACUUM

(OPTIONAL)

WORKS BEST

WHEN YOU

LET THE NOZZLE

HOVER OVER

THE WASTE.

CAUTION: THE ROTOR WILL COAST

EVEN AFTER THE ENGINE IS OFF. MAKE

SURE THIS ASSEMBLY IS FULLY

STOPPED AND DISCONNECT THE

SPARK PLUG WIRE BEFORE ANY

MAINTENANCE OR SERVICE IS

PERFORMED. IF THE ROTOR IS STILL

TURNING, IT MAY CAUSE SERIOUS

PERSONAL INJURY.

CAUTION: FOR YOUR SAFETY

AND TO MEET NATIONAL SAFETY

STANDARDS, THE DISCHARGE

DEFLECTOR AND HOPPER GUARD

MUST BE MAINTAINED IN GOOD CON-

DITION. SERIOUS PERSONAL INJURY

MAY OCCUR IF THE SHIELD OR

DEFLECTOR ARE NOT INTACT. IT IS

THE OPERATOR’S RESPONSIBILITY TO

MAINTAIN THESE SAFETY DEVICES.

▲

!

▲

!

SET SCREW

LOCK COLLAR

page 14