6

INSTALLATION

OUTDOORS: Choose a location where the

generator will not be exposed to rain, snow or direct

sunlight. Position the generator on secure, level

ground so it will not tip or slide down a hill. Place the

generator so that the exhaust fumes will not be

directed towards people.

The installation site must be free from water,

moisture, or dust. All electrical components should be

protected from excessive moisture or the insulation

system will deteriorate and result in grounding or

shorting out the generating system.

Foreign matters, such as dust, dirt, sand, lint, or

abrasive materials can cause damage to the generator

head and engine if allowed into its cooling system.

NEVER install your generator inside confined

areas. Inside installation can cause health hazards or

death.

DANGER Remember, exhaust fumes are

deadly carbon monoxide gas, and must be vented to

the outside where there are no people. Cooling air of

sufficient amounts must be allowed to flow in and

exhausted out to ensure proper cooling of the engine

and generator head.

LOAD APPLICATION

It is important to determine the total electrical load

before it is connected to the generator. The two major

factors in determining the life of a generator head are:

heat build up, caused by overloading the generator;

and corrosive contaminants that attack the wiring

insulation. If the generator is overloaded, the wires

become excessively hot and cause the insulation to

break down, reducing its ability to resist corrosive

contaminants. Over time the effectiveness of the

insulation is eliminated and a dead short can result.

Always compare the generator nameplate data

with that of the equipment to be used to ensure that

watts, volts, amperage, and frequency requirements

are suitable for operating equipment. The wattage

listed on the equipment nameplate is its rated output.

However, some equipment may require three to ten

times more wattage than its rating on the nameplate,

as the wattage is influenced by the equipment

efficiency, power factor and starting system. NOTE: If

wattage is not given on equipment nameplate,

approximate wattage may be determined by

multiplying nameplate voltage by nameplate

amperage.

VOLTS X AMPS = WATTS

Example: 120V X 5A = 600W

When connecting a resistive load such as

incandescent lights, heaters or common electric power

tools, a capacity of up to the generator full rated

wattage output can be used.

When connecting a resistive-inductive load such

as a fluorescent or mercury light, transformers or

inductive coils, a capacity of up to 0.6 times the

generator’s full rated output can be used.

Always allow the generator to reach operating

speed before a load is applied.

STARTING ELECTRIC MOTORS

Electric motors require much more current (amps)

to start than to run. Some motors, particularly low cost

split-phase motors, are very hard to start and require 5

to 7 times more current to start than to run. Capacitor

motors are easier to start and usually require 2 to 4

times as much current to start as to run. Repulsion

Induction motors are the easiest to start and require

1.5 to 2.5 times as much to start as to run.

Most fractional motors take about the same

amount of current to run them whether they are of

Repulsion-Induction (RI), Capacitor (Cap), or Split-

Phase (SP) type. The following chart shows the

approximate current required to start and run various

types and sizes of 120 volt 60 cycle electric motors

under various conditions.

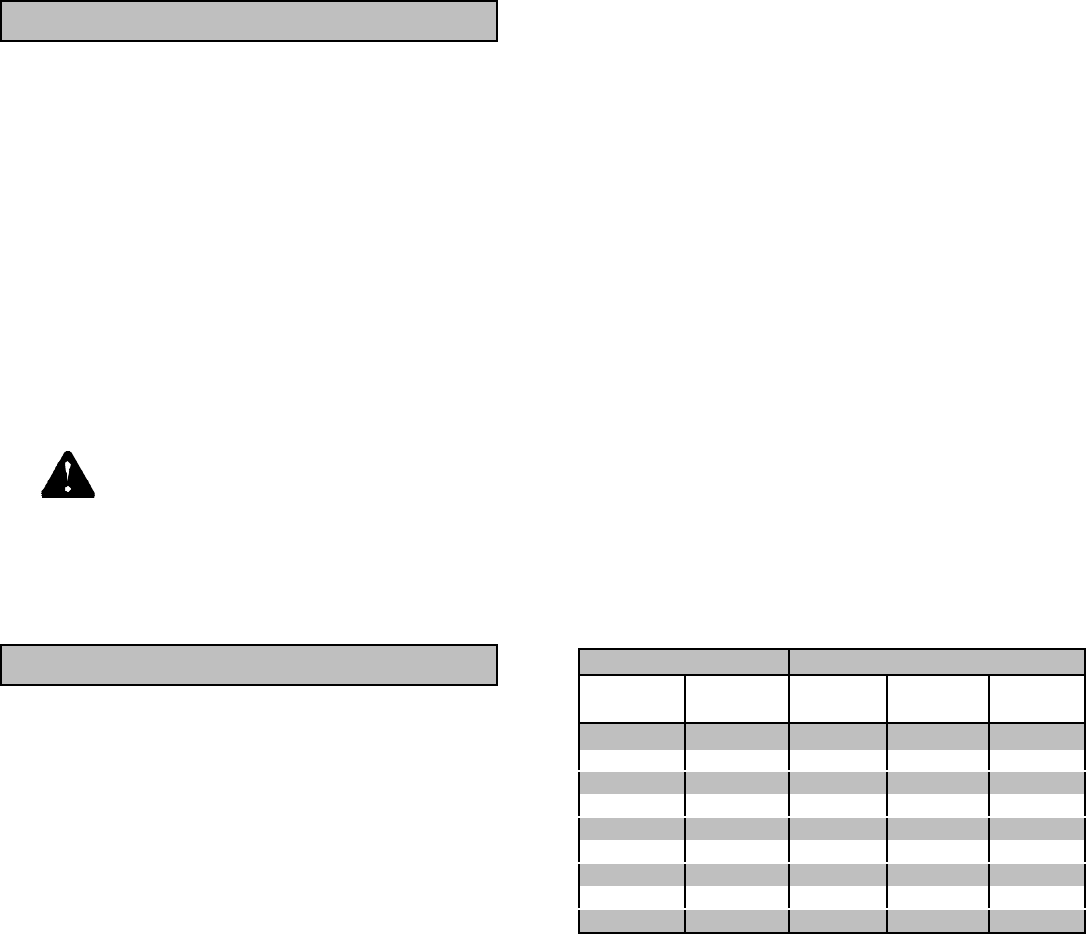

120V, 60 Hz Motors

Starting Amps

Hp motor Running

Watts

RI type Cap type SP type

1/6 525 7-11 9-18 16-22

1/4 700 9-15 12-23 22-32

1/3 875 11-18 14-29 26-35

1/2 1175 15-25 20-40 NA

1 1925 24-40 32-64 NA

1 1/2 2400 30-50 40-80 NA

2 2900 36-60 48-96 NA

3 4075 51-85 68-136 NA

5 6750 84-140 112-224 NA

The figures given above are for an average load

such as a blower or fan. If the electric motor is

connected to a hard starting load, such as an air

compressor, it will require more starting current. If it is

connected to a light load, such as a power saw, it will

require less starting current. The exact requirement

will also vary with the brand or design of the motor.

Generators respond to severe overloading

differently than the power line. When overloaded, the

engine is not able to supply enough power to bring the

electric motor up to operating speed. The generator

responds to the high initial starting current, but the

engine speed drops sharply. The overload may stall

the engine. If allowed to operate at very low speeds,

the electric motor starting winding will burn out in a

short time. The generator head winding might also be

damaged.