NATIONAL 68" SR & DL TRIPLEX – CE

®

17

BRAKE ADJUSTMENT

The foot brake is properly adjusted if it slows the

machine when depressed and can be locked when the

pedal is depressed fully.

Adjust brake tension by removing cotter pin and brake

pedal pin and turning brake clevis located under pedal on

brake rod. When adjustment is complete, attach clevis to

pedal with pin and cotter pin.

WING MOWER DRIVE BELT TENSION

Proper Belt tension allows mowers to be driven without

slippage but loose enough to be deflected slightly at a

point midway between the pulleys. An overtight belt will

cause excessive bearing wear and a slipping belt causes

excessive belt wear. IMPORTANT: Never allow oil to get

on the belt which could cause slipping.

Adjust tension by loosening set screw (Fig. E) in the

wing mower pull arm, sliding the mower rearward and

retightening set screw.

REAR MOWER DRIVE BELT TENSION

Follow the recommendations above for determining

proper tension and refer to Figure J.

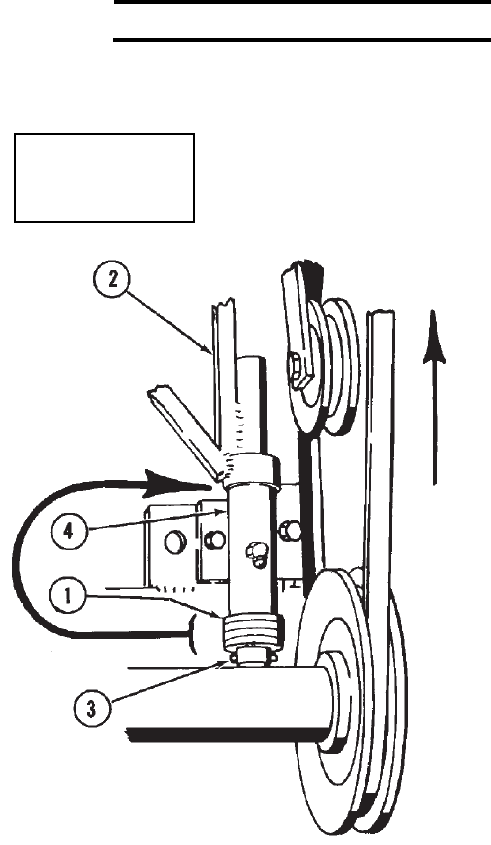

Spacers (1, Fig. J) are provided on the rear mower Pull

Rod (2, Fig. J) to adjust the belt tension. Remove Pin (3,

Fig. J) from the end of the pull rod and slip out the pull rod

from the Pivot Tube (4, Fig. J). Move as many spacers as

necessary to the location indicated and reassemble.

ENGINE DRIVE BELT (Engine to Main Countershaft)

Belt tension is increased by loosening the four engine

mounting bolts and sliding the engine forward in the

slotted frame holes. Test for the proper tension as detailed

for the wing mower adjustment. When tension is correct,

tighten all the bolts securely.

MAIN DRIVE BELT (Main Countershaft to Rear Drive)

Belt tension is increased by loosening the four bolts

holding the Main Countershaft Housing (45, Fig. 3) and

sliding the housing forward in the slotted frame holes.

NOTE - It will probably be necessary to loosen or remove

belt guards to reach the adjustment bolts. Also, if this belt

is adjusted, it will probably be necessary to readjust the

engine belt.

FRONT

OF

MACHINE

NOTE

Guards removed

to show detail

FIGURE J