SP7060 PAVEMENT SAW • OPERATION MANUAL — REV. #0 (02/13/09) — PAGE 53

MAINTENANCE

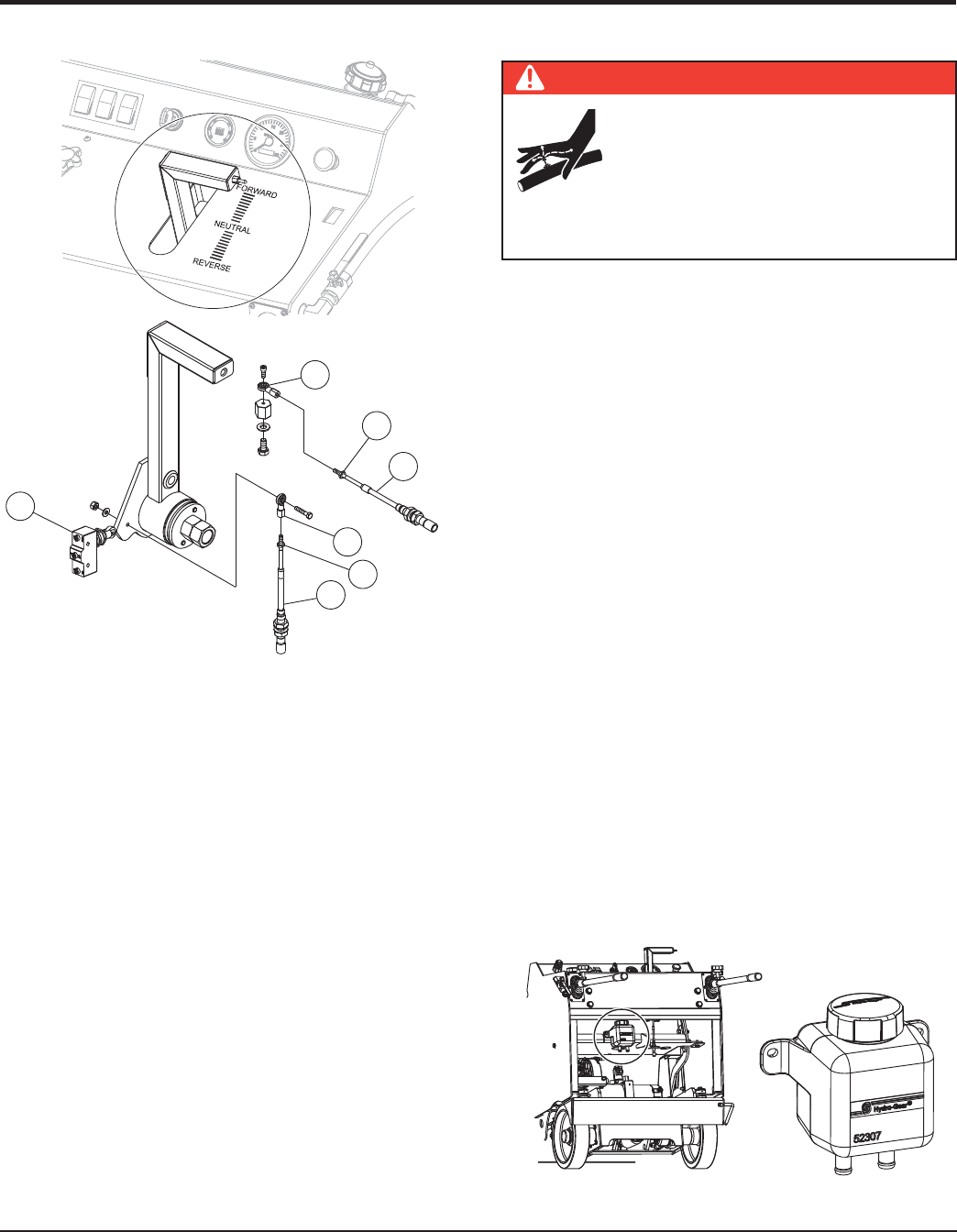

F-N-R CONTROL ADJUSTMENT

Control (cable) adjustment for the F-N-R should not normally

be necessary; however, some adjustment can be made on

each of the rod end adjustment nuts. See Figure 64.

Figure 64. F-N-R Control Adjustment

1

3

2

1

2

3

4

1. Adjustment Nut

2. Rod End

3. Push-Pull Cable

4. Neutral Safety Switch

HYDRAULIC SYSTEM MAINTENANCE

Many hydraulic problems are a result of low fluid levels.

Before checking any other possibilities, make sure the

hydraulic fluid level is correct. See Figure 66 for hydraulic

components. Hydraulic problems could be a result of the

following:

1. Incorrect hydraulic fluid level.

2. Plugged hydraulic oil filter

3. Loose or leaking fittings.

4. Ruptured/damaged hydraulic lines.

5. Faulty hydraulic pump.

Hydraulic Oil System

1. Check hydraulic oil level daily.

2. When checking or adding hydraulic oil, place the

machine so the saw frame is level to get an accurate

reading.

3. Hydraulic oil should be 1/2" to 1" in the Oil Reserve

when cold.

4. If hydraulic oil level is low add oil to 1/2" to 1".

5. Use 15W-40 premium grade engine oil.

6. Change oil and filter annually. See Figure 65.

DANGER — Hydraulic Leaks

NEVER

use your hand to find hydraulic

leaks. Use a piece of wood or cardboard.

Hydraulic fluid injected into the skin must

be treated by a knowledgable physician

immediately or severe injury or death can

occur.

Figure 65. Oil Reserve Fill Line