10

MAINTENANCE SCHEDULE

Perform these required maintenance procedures at the

frequency stated in the table. These procedures should also be

a part of any seasonal tune-up.

NOTE: Some maintenance procedures may require special

tools or skills. If you are unsure about these procedures,

take your unit to a MTD or other qualified service dealer.

Call 1-800-800-7310 for more information.

NOTE: Maintenance, replacement, or repair of the emission

control devices and system may be performed by a

MTD or other qualified service dealer. Call 1-800-800-

7310 for more information.

FREQUENCY MAINTENANCE REQUIRED REFER TO

Before starting engine

Fill fuel tank with fresh fuel

Check oil

Page 7

Page 10

Every 10 hours Clean and re-oil air filter Page 11

First change at 10 hours

Second change at 25 hours

Every 25 hours thereafter

Change oil

Change oil

Clean spark arrestor

Page 11

Page 11

Page 14

Every 25 hours Check spark plug condition and gap Page 14

CHECKING THE OIL LEVEL

The importance of checking and maintaining the proper oil

level in the crankcase cannot be overemphasized. Check oil

before each use:

1. Stop the engine and allow oil to drain into the crankcase.

2. Place the unit on a flat, level surface to get a proper oil

level reading (Fig. 9).

3. Keep dirt, grass clippings and other debris out of the

engine. Clean the area around the oil fill plug/dipstick

before removing it.

4. Remove the oil fill plug/dipstick and wipe off oil. Reinsert it

all the way back in.

5. Remove the oil fill plug/dipstick and check the oil level. Oil

should be up to the top of the dipstick (Fig. 15).

6. If the level is low, add a small amount of oil to the oil fill hole

and recheck (Fig. 16). Repeat this procedure until the oil level

reaches the top of the dipstick.

NOTE: Do not overfill the unit.

MAINTENANCE AND REPAIR INSTRUCTIONS

WARNING: To prevent serious injury, never

perform maintenance or repairs with unit running.

Always service and repair a cool unit. Disconnect the

spark plug wire to ensure that the unit cannot start.

CAUTION: To prevent extensive engine wear

and damage to the unit, always maintain the proper

oil level in the crankcase. Never operate the unit

with the oil level below the bottom of the dipstick.

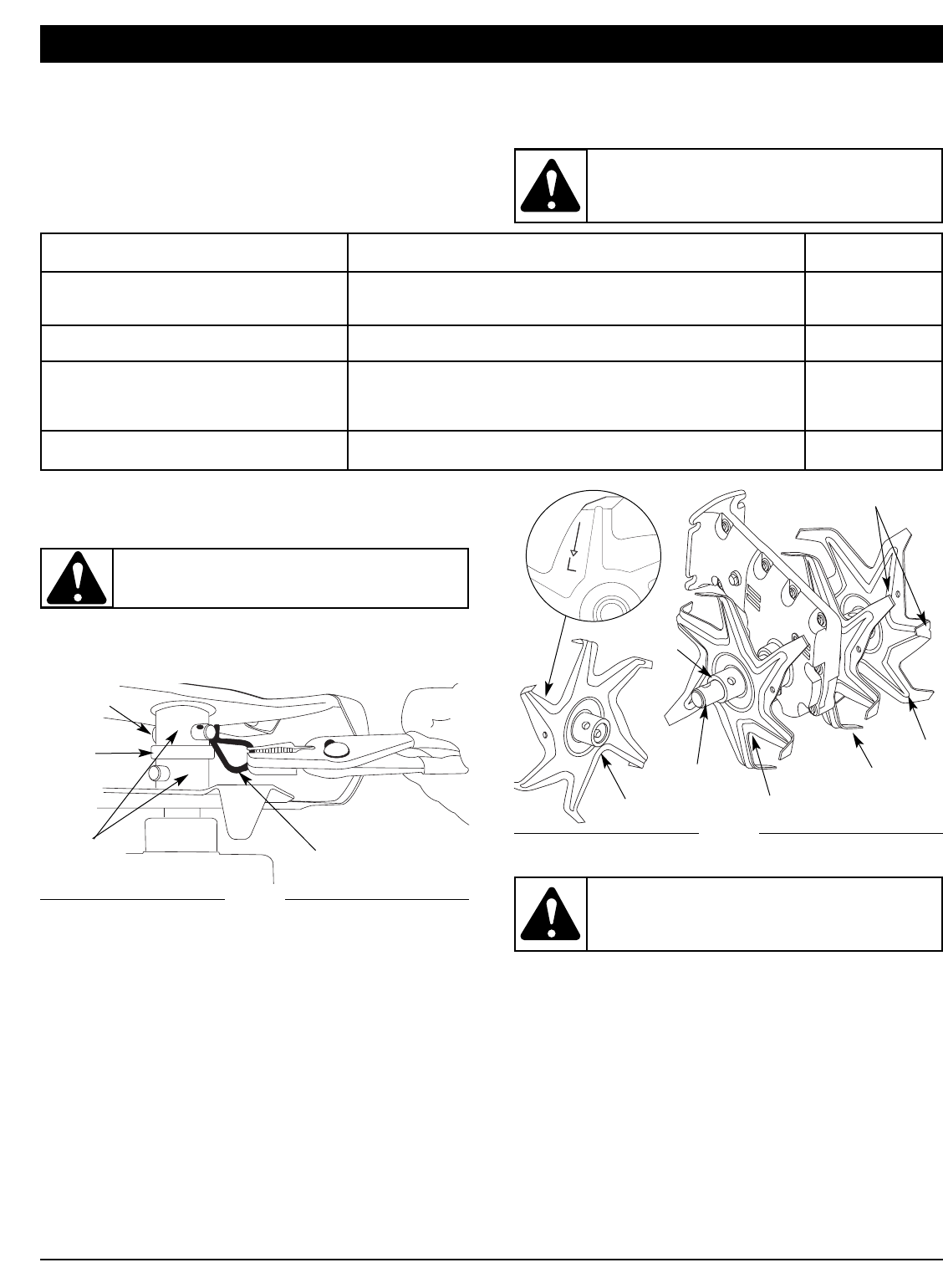

Fig. 12

Clevis Pin Clip

Felt

Washer

Shaft

Felt

Washer

Tine

Hubs

Stagger Tips

R

R

L

L

Clevis Pin

TINE REMOVAL AND REPLACEMENT

Replace all four (4) tines at the same time, because they will

wear evenly through normal use. Work on one side at a time.

1. Put the On/Off Stop Control in the STOP (O) position

and disconnect the spark plug wire.

2. Remove the clevis pin clips and clevis pins (Fig. 11).

3. Remove the tines and felt washers from the shaft.

4. Clean and oil the shaft.

5. The tines are stamped with the letter "R" or "L" to

identified their position on each side of the gearbox when

facing the front of the unit.

6. Replace the tines and felt washers onto the shaft with the

hubs on the tines facing each other.

7. Before you reinstall the clevis pins and pin clips, ensure

that the tips on the tines are staggered when compared to

each other (Fig. 12).

8. Repeat this procedure on the opposite side.

NOTE: When installed correctly, there will be an "R" and "L"

tine on both the sides of the gearbox and the tips of

the tines. These letters will line up in the same

direction for each side. It is important that the tines are

installed correctly.

Fig. 11

WARNING: To prevent serious personal injury,

always wear heavy gloves when handling the

tines.