15

5. If adjustment is necessary, loosen the jam nut

on the traction drive cable, and thread cable in

or out as necessary.

6. Tighten the jam nut to secure the cable when

correct adjustment is reached. Reassemble the

frame cover with six self-tapping screws.

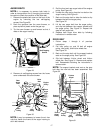

Figure 26

Note: If you had earlier placed plastic film under

the gas cap, be sure to remove it once the

adjustment to the traction drive clutch is done and

the snow thrower frame is re-installed.

ADJUSTING AUGER CLUTCH

To adjust the auger clutch, refer to the Final

Adjustments section on page 10.

ADJUSTING SHIFT ROD

1. Remove the hairpin clip and flat washer from

the ferrule and remove the ferrule from the shift

lever. Place the shift lever in the fifth (5) or the

fastest forward speed position.

Models 642, 662:

2. Push up on the shift arm assembly as far as it

will go. Thread the ferrule up or down the shift

rod and align with the lower hole on the wider

side of the shift lever assembly behind the

handle panel. Secure the ferrule to the shift arm

assembly again with the hardware earlier

removed.

Model 614, 644, 664:

3. Push down on the shift arm assembly as far as

it will go. Thread the ferrule up or down the shift

rod and align it with the hole closest to the shift

knob on the narrow side of the shift lever

assembly behind the handle panel.

NOTE: Make certain to check for correct

adjustment of the shift rod as instructed in the Final

Adjustments section before operating the snow

thrower.

CARBURETOR ADJUSTMENT

WARNING: If any adjustments are

made to the engine while the engine is

running (e.g. carburetor), keep clear of

all moving parts. Be careful of heated

surfaces and muffler.

Minor carburetor adjustment may be required to

compensate for differences in fuel, temperature,

altitude and load.

Refer to the separate engine manual packed with

your unit for carburetor adjustment information.

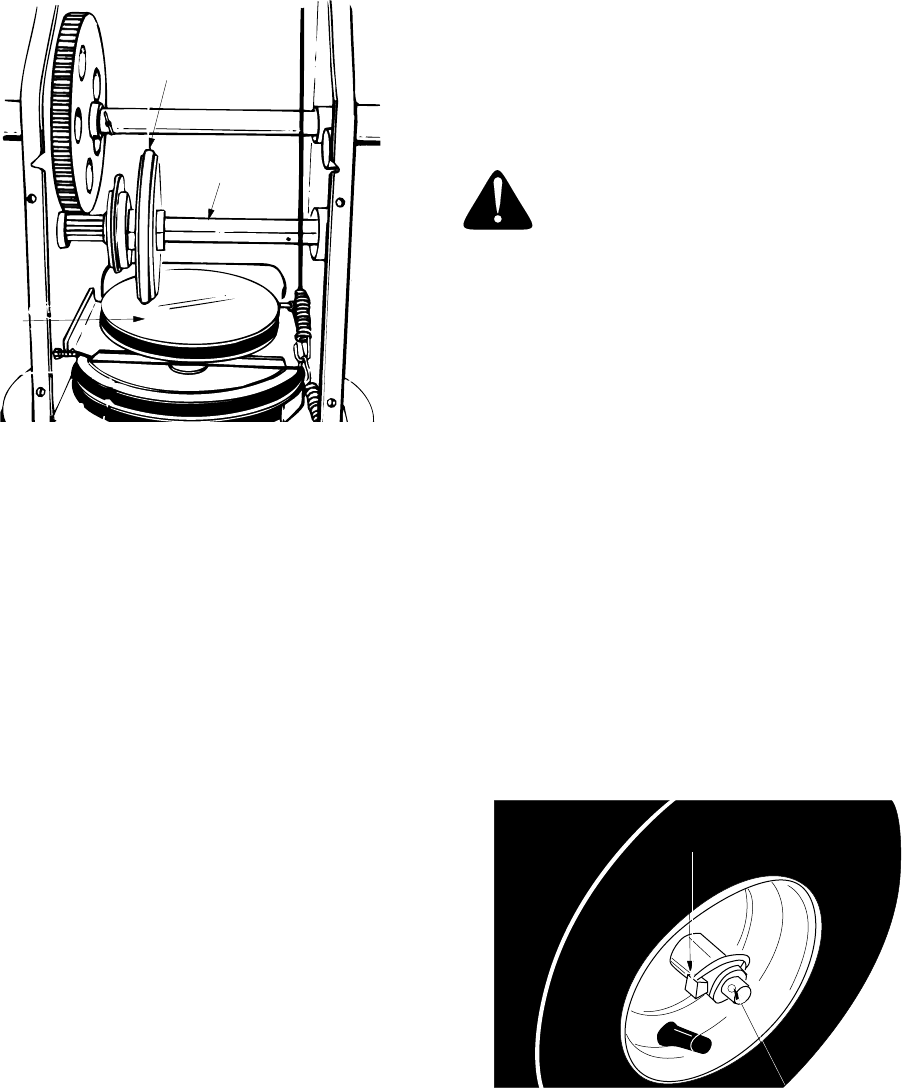

DRIVE WHEELS

The wheels may be adjusted for two different

methods of operation. The adjustment is made by

placing the klick pins in one of two different holes on

the right side of the unit. See Figure 28.

1. One Wheel Driving—Place klick pin in the

outside axle hole on the right side. This position

gives power drive to the left wheel only, making

the unit easier to maneuver.

Both Wheels Driving—Place klick pin in the hole in

the hub next to the rim on the right side. This

position is good for heavy snow as there is power

drive in both wheels.

Figure 27

Drive

Plate

Gear

Shaft

Friction

Wheel

Klick Pin in Hole

in Hub Next to Rim

Outside Hole

in Axle