6

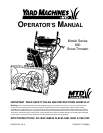

Figure 6

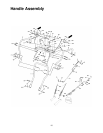

Figure 7

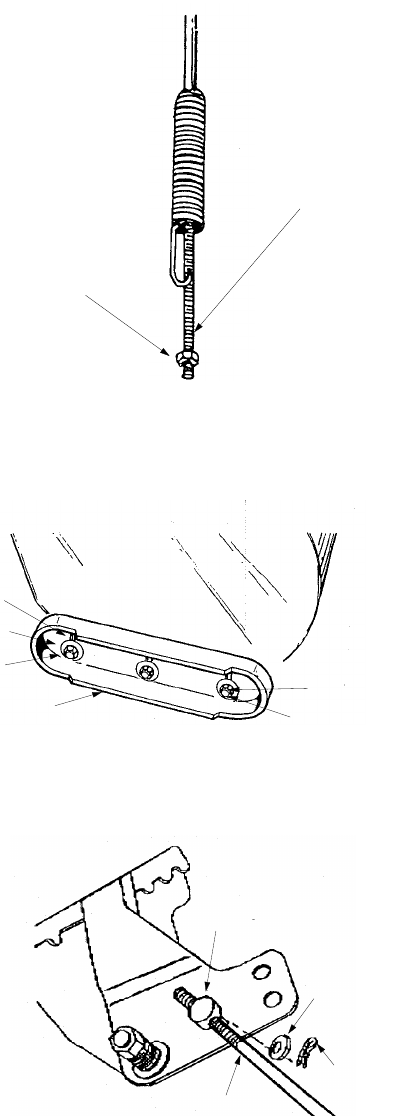

Figure 8

FINAL ADJUSTMENTS

Auger and Traction Drive Clutch Adjustment

To check the adjustment of either drive clutch, push

forward on the clutch grip (depress the rubber

bumper). There should be slack in the cable.

Release the clutch grip. The cable should be

straight, but not tight. Make certain you can depress

the clutch grip against the handle completely.

If necessary, thread lock nut up to increase tension

or down to decrease tension. (See Figure 6.)

Skid Shoe Adjustment

(See Figure 7)

The space between the shave plate and the ground

can be adjusted. For close snow removal, place

skid shoes in the low position. Use middle or high

position when area to be cleared is uneven. See

Figure 7.

Adjust skid shoes by loosening the six hex nuts and

carriage bolts and moving skid shoes to desired

position. Make certain the entire bottom surface of

skid shoe is against the ground to avoid uneven

wear on the skid shoes. Tighten nuts and bolts

securely.

Shift Lever Adjustment

(See Figure 8)

If unit does not engage properly into first gear, it

may be necessary to remove the cotter pin and

washer from the shift rod and thread the ferrule one

counterclockwise turn.

TIRE PRESSURE (Pneumatic Tires)

The tires are over-inflated for shipping purposes.

Check tire pressure and reduce to 15 to 20 psi.

(Check sidewall of tire for manufacturer’s

recommendation)

NOTE:

If the tire pressure is not equal in both

tires, the unit may pull to one side or the other.

Lock Nut

Cable

High

Middle

Low

Skid

Shoe

Hex Nuts

Carriage Bolts

Flat Washer

Cotter Pin

Ferrule

Shift Rod