11

Engine

Listed below are general recommendations about

maintaining your snow thrower engine. For further

details, refer to the accompanying engine manual.

Check Oil Level

• Before operating snow thrower, check the oil level.

• With engine on level ground, oil must be to FULL

mark on dipstick. See Figure 8.

• Stop engine and wait several minutes before

checking oil level. Remove oil fill cap and dipstick.

• Wipe dipstick clean, insert it into oil fill hole and

tighten securely.

• Remove dipstick and check. If oil is not up to the

FULL mark on dipstick, add oil.

Figure 8

Change Oil

Change engine oil after first two hours of operation and

every 25 hours thereafter.

In order to change oil, you will have to first drain the

spent engine oil from the engine and then refill with

fresh oil.

• Drain oil while engine is warm. Remove oil drain

plug located at the bottom of the recoil starter of the

engine. Catch oil in a suitable container.

• When engine is drained of all oil, replace drain plug

securely.

• Remove the dipstick from the oil fill. For location of

the oil fill, see Figure 6. Pour fresh oil slowly

through the plug. Replace dipstick.

• Check and make sure that the level of oil is up to

the FULL mark on the dipstick.

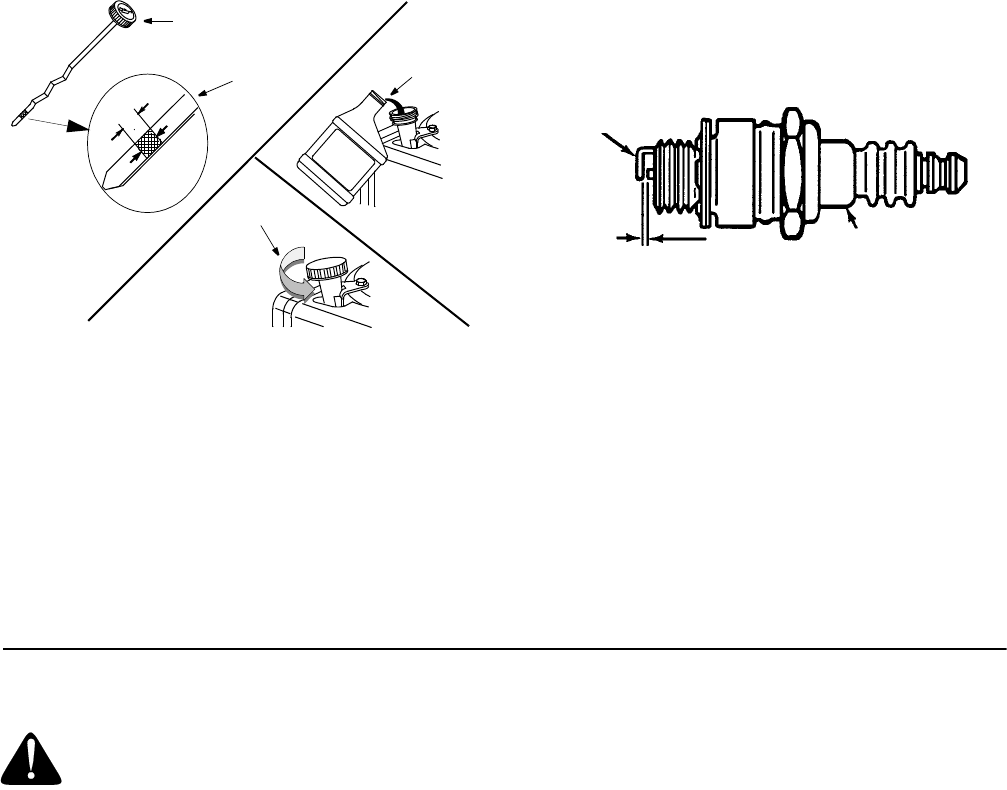

Service Spark Plug

Clean spark plug and reset the electrode gap to 0.030"

at least once a season or every 100 hours of operation;

replace every 200 hours of operation.

• Clean area around the spark plug base.

• Remove and inspect the spark plug.

• Replace the spark plug if electrodes are pitted,

burned, or the porcelain is cracked. See Figure 9.

NOTE: Do not sandblast spark plug. Spark plug should

be cleaned by scraping or wire brushing and washing

with a commercial solvent.

Figure 9

Check V-Belts

Follow instructions below to check condition of drive

belts every 50 hours of operation.

• Remove the plastic belt cover on the front of the

engine by removing two self-tapping screws.

• Visually inspect for frayed, cracked, or excessively

worn out belts. Replace, if necessary, following

instructions on page 12.

SECTION 6: SERVICE & ADJUSTMENT

Shave Plate and Skid Shoes

The shave plate and skid shoes on the bottom of the

snow thrower are subject to wear. These should be

checked periodically and replaced when necessary.

• Remove two carriage bolts, belleville washers and

hex nuts which secure each skid shoe to the auger

housing. See Figure 10.

• Reassemble new skid shoes with the hardware just

removed. Make sure the cupped side of the washer

goes against the skid shoe and that the skid shoes

are adjusted to be level.

• To remove shave plate: Remove both skid shoes

and hardware including carriage bolts, belleville

washers and hex nuts which attach shave plate to

the snow thrower housing. For location of shave

plate, see Figure 10.

AB

C

A

D

D

F

I

L

L

8

o

z

.

Dipstick

Fill up if

needed

Tighten

dipstick

Read oil

level

Porcelain

Electrodes

.030”

Gap

WARNING: Before servicing, repairing, or

inspecting, disengage all clutch levers and stop

engine. Wait until all moving parts have come

to a complete stop. Disconnect spark plug wire

and ground it against the engine to prevent

unintended starting.