20

Note:

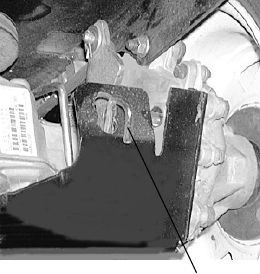

If you wish to move the mower by

pushing, you must release the dynamic brak-

ing. Locate the levers at the rear of the mower.

Pull both levers out and lock in position. After

pushing the mower to the desired location,

return both levers to the operating position

(See photo below)

.

When the mower is parked with the engine running

and the steering levers opened out in the neutral

position, the parking brakes should be applied. The

parking brakes are drum-type brakes mounted on

each traction wheel.They are both engaged by the

same operating lever.

1.

Adjustments:

The parking brake handle is an

overcenter lever that should engage with

moderate force.

Note:

To increase parking brake capacity

tighten the brake rods going back to the brake

arms equally. Tighten rods one full turn and

check parking capacity. Repeat Step.

To adjust either brake individually, disconnect the

brake rod from the brake arm by removing the cotter

pin from the clevis pin and pulling the clevis pin from

the brake clevis. Loosen the hex nut and turn the

brake clevis in a clockwise direction one full turn

looking down the brake rod. This will tighten the brake

about .040 inch. Tighten the hex nut and reassemble

the brake clevis to the brake shaft assembly. Normally,

both brakes should be adjusted and equal amount.

2.

Repair:

The mower is equipped with internal

wet drum brakes and will not normally require

maintenance. If they are not working properly,

please contact your service center.

F. Hydraulic System

1.

Hoses:

Check the hoses from the hydraulic

oil tank to the oil filter to the hydraulic lines

daily for leaks or abrasion and replace any

damaged hoses. Make certain there are no

kinks or twists in any hose.

2.

Hydraulic Oil Tank and Filter:

Note:

Change the hydraulic oil and the oil

filter after the first 50 hours of operation and

every 500 hours thereafter.

To drain the hydraulic oil tank, place a 2 gallon drain

pan under the drain plug on the bottom of the

hydraulic oil tank. Remove the drain plug, drain the

tank, then replace the plug. Place the drain pan under

the filter and remove the filter by unscrewing in a

counterclockwise direction. The filter will be full of oil,

so empty it into the drain pan. You don’t have to drain

the rest of the hydraulic system. Fill the replacement

filter with a good grade of 20W-50 oil and lubricate the

sealing surface. Screw the filter onto the filter base

until it seats and then another one-half turn to seal.

Note:

Always wipe off the hydraulic tank fill

cap and the area around it before removing the

cap to prevent dirt from contaminating the oil.

Remove the fill cap and fill the tank with the same

20W-50 oil selected for the filter until the oil level is up

to the level of the second hole in the fill tube. Leave

this air space for expansion. Start the engine and let it

run at idle for about five minutes. Check the filter for

leaks. Idling the engine and the pumps in this way will

purge any air from the system. Shut off the engine

and recheck the oil level in the tank. Top-off if

necessary until the oil level is up to the second hole n

the fill tube.

Note:

After unit is up to operating tempera-

ture, turn off engine and re-check hydraulic

oil. If oil appears foamy or contains excessive

air bubbles, DO NOT OPERATE UNIT. Contact

service technician.

3.

Hydrostatic Transmissions and motors:

The pumps are the hardest-working compo-

nents in the hydraulic system. They are in

operation all the time the engine is running.

Because of extremely close tolerances, wear

is an important factor in their life.

Contami-

nants

in the hydraulic oil and

cavitation

does

the greatest harm to the pumps. Cavitation is

a blockage in the supply lines that produces a

partial vacuum causing violent bubbling in the

hydraulic oil in the pump.

Check the two suction hoses (the hoses con-

nected to the filter) daily before starting the

engine. Look for a flattened condition or any

leaks and repair or replace as necessary. A

flattened or leakng suction hose will permit

Hydro Release Levers