12

Wheels

• The wheels require no lubrication. However, if the

wheels are removed for any reason, lubricate the

surface of the axle bolt and the inner surface of the

wheel with light oil. Engine oil may also be used.

When tipping the unit, empty the fuel tank and keep

engine spark plug side up.

Figure 13 : Lubrication Chart

Blade Care

• Periodically inspect the blade adapter for cracks,

especially if you strike a foreign object. Replace

when necessary.

WARNING: When removing the cutting

blade for sharpening or replacement, protect

hands by using heavy gloves or a rag to grasp

the cutting blade.

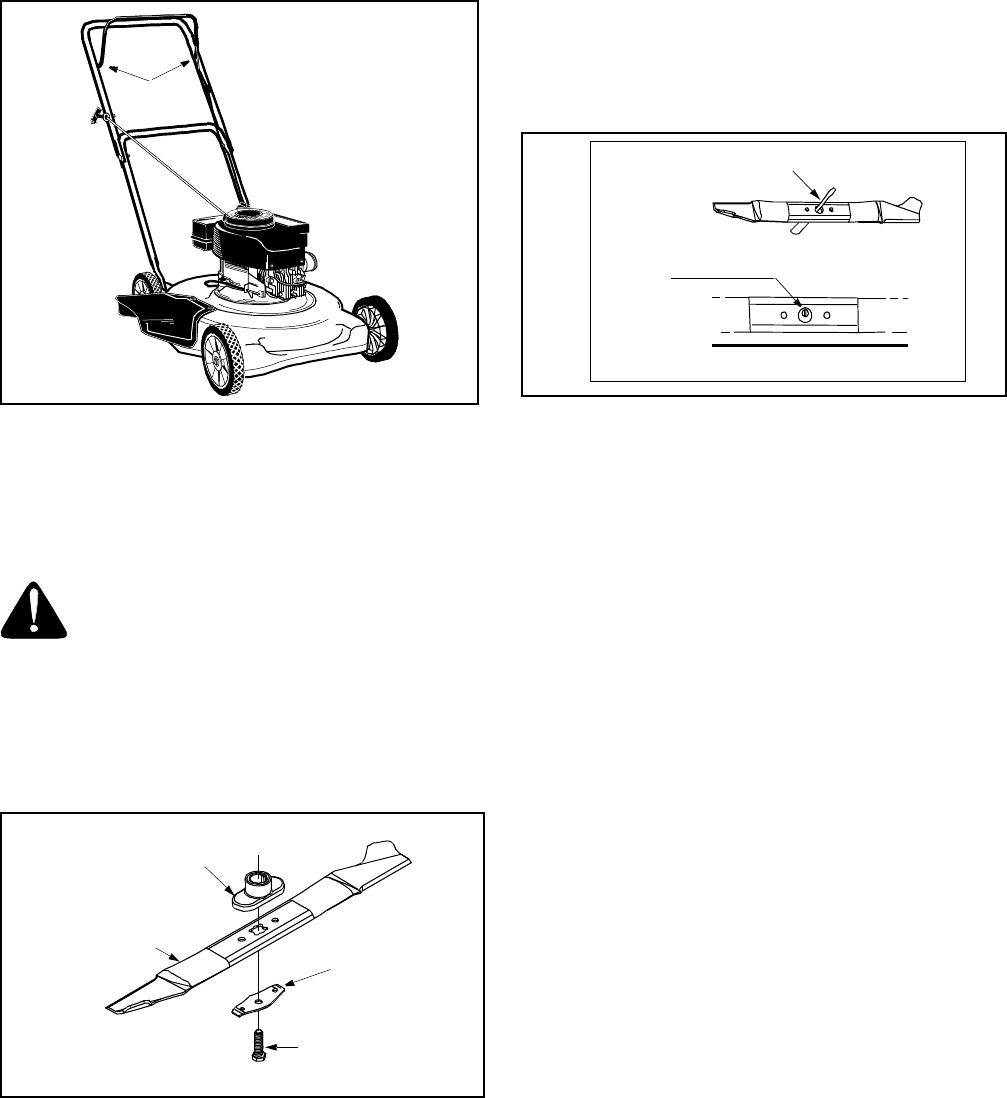

To remove blade

• Remove the bolt and blade support or bell washer

which hold the blade and adapter to the engine

crankshaft. See Figure 14. Remove the blade and

adapter from the crankshaft.

Figure 14

To balance blade

• When sharpening the blade, follow original angle of

grind as a guide. It is extremely important to grind

off all edges equally to keep the blade balanced.

NOTE: An unbalanced blade will cause excessive

vibration when rotating at high speeds and may cause

damage to the mower and/or personal injury.

• Test the blade by balancing it on a round shaft

screwdriver. See Figure 15.

• Remove metal from the heavy side until it balances

evenly. Always remove blade from the adapter for

the best test of balance.

Figure 15

To reassemble blade

• Lubricate the engine crankshaft and the inner

surface of the blade adapter with light oil (or engine

oil). Also lubricate the bolt holes, bolts and inner

surface of the nuts.

• Install the blade adapter on the crankshaft with the

“star” away from the engine. Refer to Figure 14.

Place the blade with the side marked bottom (or

with part number) facing away from the adapter.

• Align the blade bell support over the blade with the

tabs in the holes of the blade and insert the hex

bolt. Tighten the hex bolt to the torque listed in the

“Blade Mounting Torque” section below.

Blade Mounting Torque

Center Bolt: 450 in. lbs. min., 600 in. lbs. max.

IMPORTANT:

To ensure safe operation, all nuts and

bolts must be checked periodically for correct tightness.

Replacing Rear Flap

• To remove rear flap, compress the hinge clips and

remove from the slots in rear of deck.

• Attach new rear flap by placing new spring clips in

the slots on the flap. Then compress the spring

clips and reinsert in slots in rear of deck.

Engine

• Follow engine manual for instruction and schedule

of maintenance and lubrication.

Lube

Blade Adapter

Blade

Blade

Bell

Support

Hex Bolt

1. Insert screw driver through hole

2. Blade should be parallel to ground

Screw

Driver

Ground

Blade