PTO DRIVELINE

WARNING: BEFORE ATTEMPTING TO

OPERATE THIS SPREADER, READ AND STUDY

ALL SAFETY INFORMATION. IN ADDITION, MAKE

SURE THAT EVERY INDIVIDUAL WHO OPERATES

OR WORKS WITH THE SPREADER, WHETHER

FAMILY MEMBER OR EMPLOYEE, IS FAMILIAR

WITH THESE SAFETY PRECAUTIONS.

WARNING: DISCONNECT PTO DRIVE SHAFT

AND HYDRAULIC HOSES (RELIEVE HYDRAULIC

PRESSURE) BEFORE CLEANING, ADJUSTING,

LUBRICATING OR SERVICING THIS SPREADER.

FAILURE TO HEED MAY RESULT IN SERIOUS

PERSONAL INJURY OR DEATH.

The Meyer 8720/8865 Industrial Series Spreader is

equipped with a cutout type clutch on the implement half

of the PTO driveline. The clutch is designed to limit the

amount of torque transferred to the machine through the

driveline. If excessive torque is developedthe clutch will

disengage. A loud ratcheting sound will be heard and

the transfer of power to the machine will be disrupted.

To reengage the machine simply shut down the PTO

and allow the driveline to come to a stop. The PTO can

then be reengaged to restart the spreader. The cutout

clutch will either reengage upon shut down of the PTO

or just before it comes to a complete stop.

The cutout clutch will disengage if start up is done in an

abrupt or reckless manner. It also will disengage from

foreign materials entering the spinner area of the

spreader. It may also be possible to disengage the

clutch by overloading or flooding the spinners with free

flowing or liquid manure. If PTO clutch fails to reengage

it will be necessary to remove the foreign object from the

spreader before restarting. THERE IS NO FIELD

ADJUSTMENT ON THE CUTOUT CLUTCH.

DANGER: NEVER ENTER THE SPREADER

BOX FOR ANY REASON WITHOUT FIRST

STOPPING THE TRACTOR, SHUTTING THE

TRACTOR OFF AND REMOVING THE KEY,

SETTING THE PARKING BRAKE AND

DISCONNECTING THE PTO DRIVELINE FROM THE

TRACTOR. DO NOT ALLOW OTHERS IN THE BOX.

ROTATING AUGERS CAN CRUSH AND

DISMEMBER. FAILURE TO HEED MAY RESULT IN

SERIOUS PERSONAL INJURY OR DEATH.

DRIVELINE ATTACHMENT

The cutout clutch end of the PTO driveline must always

be attached to the implement. The PTO driveline is

equipped with a 1 3/8-6 spline on the implement half for

attaching to the spreader. Remove the M17-hexagon

bolt from the splined hub and slide the PTO onto the im

-

plement splined input shaft. Install the hexagon bolt

through the hub being sure the bolt is falling into the

groove on the splined shaft. Torque tight using a metric

size M17 6-point socket and torque down to 75 ft. lbs. A

M17 6-POINT METRIC SOCKET MUST BE USED AS

ROUNDING OF HEXAGON BOLT AND INACCU

-

RACY OF TORQUE SETTINGS COULD OCCUR.

If removal of the M-17 hexagon bolt is necessary, use

the same M-17 6-point socket and loosen bolt 1/2 turn.

Insert a 1/4” drift punch in the hole on the opposite side

of the hexagon bolt and tap to loosen the seated portion

of the bolt from the splined hub. Loosen in 1/2 turn incre-

ments and tapping to loosen. After bolt seat has been

released, remove the bolt. If bolt is not unseated, dam-

age to the hexagon bolt will occur.

Attach the shield safety chain to a suitable area on the

spreader, preferably to the implement PTO steel shield.

PTO SETUP

DANGER: NEVER ATTEMPT TO PERFORM

ANY WORK ON THIS MACHINE FOR ANY REASON

WITHOUT FIRST STOPPING THE TRACTOR,

SHUTTING THE TRACTOR OFF AND REMOVING

THE KEY, SETTING THE PARKING BRAKE AND

DISCONNECTING THE PTO DRIVELINE FROM THE

TRACTOR AND DISCONNECTING THE HYDRAULIC

HOSES AND RELIEVING HYDRAULIC PRESSURE.

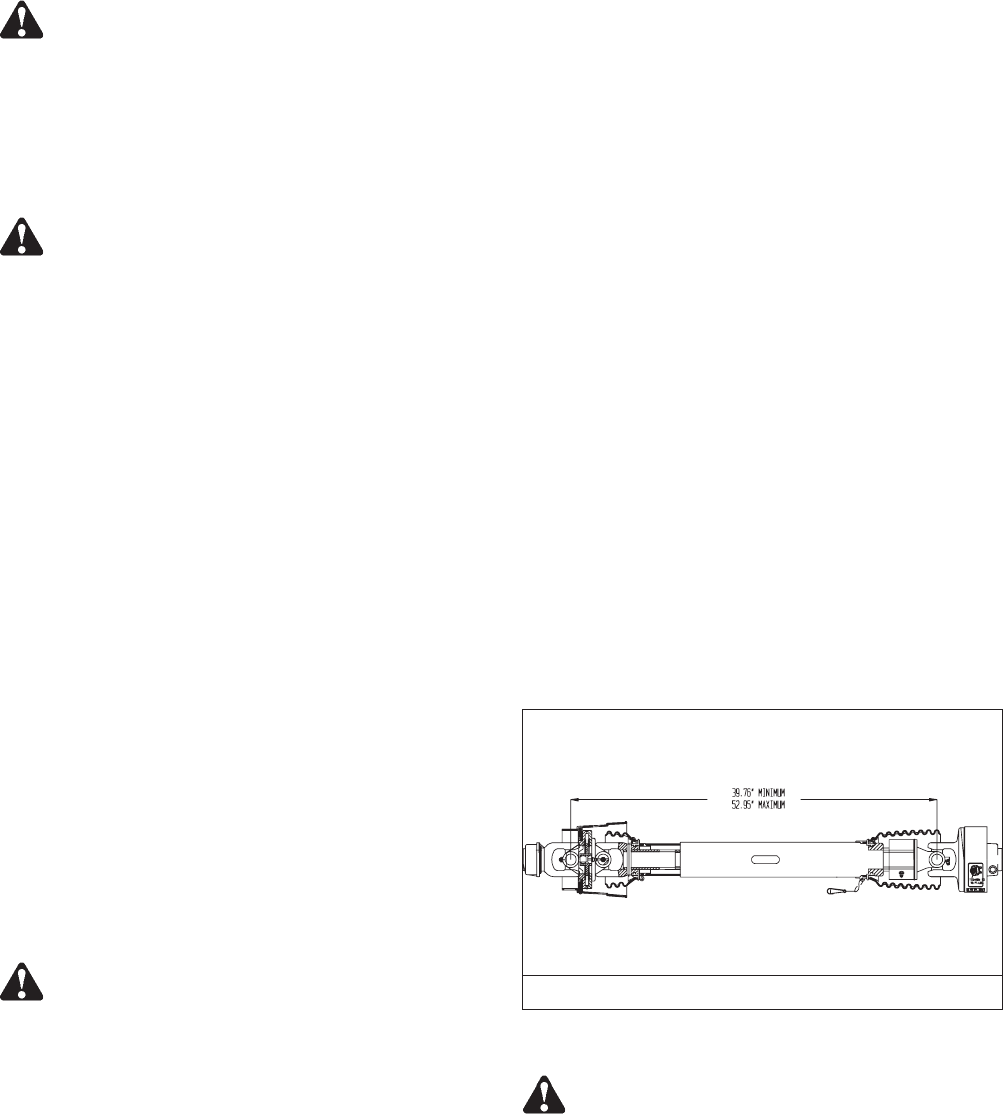

Model 8720/8865 -15-

FIGURE 5. PTO DRIVELINE