ADJUSTMENTS

WARNING: DISCONNECT PTO DRIVE SHAFT AND HYDRAULIC HOSES (RELIEVE HYDRAULIC

PRESSURE) BEFORE CLEANING, ADJUSTING, LUBRICATING OR SERVICING THIS SPREADER. FAILURE

TO HEED MAY RESULT IN SERIOUS PERSONAL INJURY OR DEATH.

FRONT DRIVE ROLLER CHAINS

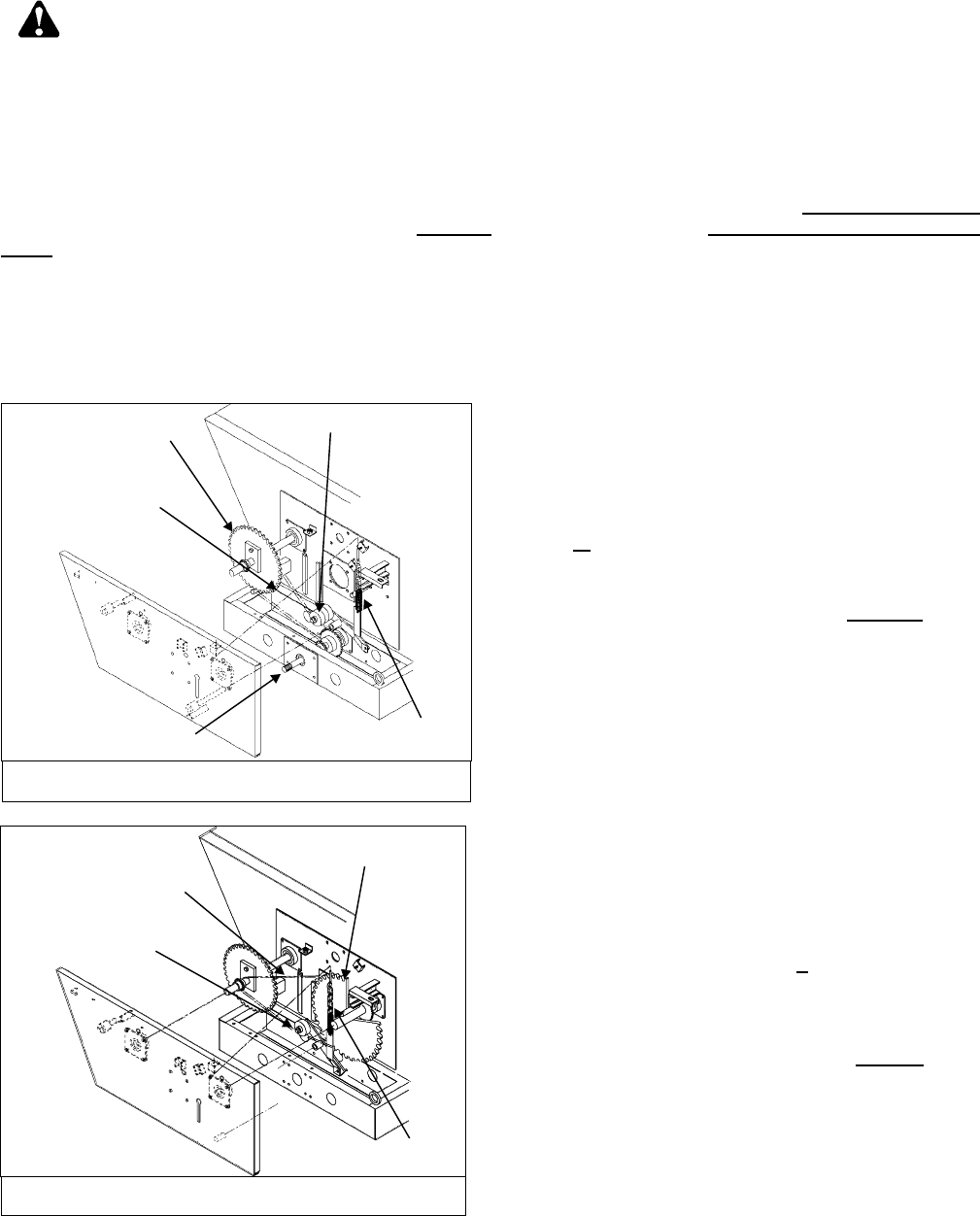

There are six roller chain drives located at the front of the spreader. Regularly check that all tensioning springs are in

serviceable condition for automatic roller chain tightening. Manually adjust spring tensioners (as needed) by turning

double locknuts on all tensioning bolt/idler assemblies. Proper roller chain tension is when 1/4" to ½" deflection

occurs on the slack side of the chain. Regularly re-check all roller chain tensions. Keep all roller chains tight at all

times! For clarity purposes, the following illustrations detail each roller chain reduction separately.

NOTE: The side bars of the roller chains will wear into the idler nylon rollers up to the rollers of the roller chain forming

grooves. These grooves will serve as a guide when the roller chain loosens due to normal use. From this point on,

after tightening, the idler nylon rollers should run for hundreds of hours without any noticeable wear.

Model 8720/8865 -17-

FIGURE 7. SECOND CHAIN DRIVE

IDLER NYLON

ROLLER

ROLLER CHAIN

LH TOP SPROCKET

SPRING LOADED

ADJUSTER

The first chain drive (PTO input shaft to the large RH top

sprocket, figure 8) is automatically tensioned by a spring

loaded idler nylon roller. The extension spring should

extend 2”

from its neutral 5” total length.

Manual adjustment for the automatic tensioning idler,

nylon roller assembly is located at the left rear

of the

spreader’s front bearing mounting plate.

The second chain drive (large RH top sprocket to the

large LH top sprocket, figure 7) is automatically

tensioned by a spring loaded idler nylon roller. The

extension spring should extend 2

“ from its neutral 5"

total length.

Manual adjustment for the automatic tensioning idler,

nylon roller assembly is located at the left rear

of the

spreader’s front bearing mounting plate.

FIGURE 8. FIRST CHAIN DRIVE

RH TOP

SPROCKET

ROLLER

CHAIN

IDLER NYLON

PTO

INPUT

SPRING LOADED

ADJUSTER