13

BAR MAINTENANCE

Ifyoursaw cutstooneside,hasto beforced

throughthecut,orbeenrunwithanimproper

amount of bar lubrication it may be neces-

sary to service your bar.

Awornbarwilldamageyourchainandmake

cutting difficult.

After each use, ensure ON/STOP switch is

intheSTOP position, thencleanallsawdust

from the guide bar and sprocket hole.

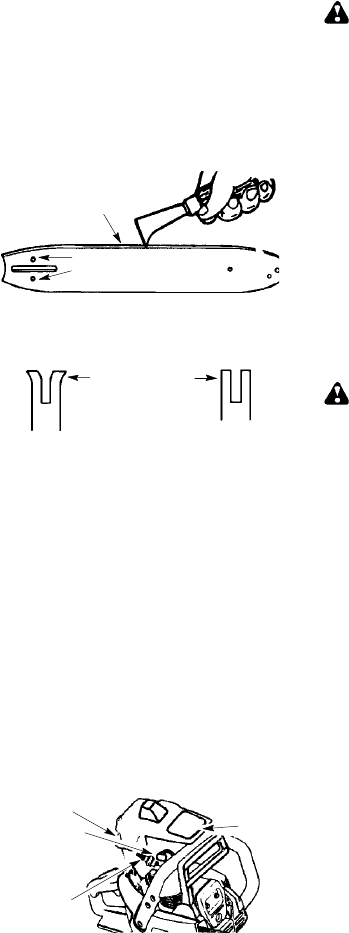

To maintain guide bar:

S Move ON/STOP switch to the STOP posi-

tion.

S Loosen and remove chain brake nuts and

chain brake. Remove bar and chain from

saw.

S Cleantheoilholes a ndbargrooveaftereach

5 hours of operation.

Remove Sawdust From

Guide Bar Groove

Oil Holes

S Burring of guide bar rails is a nor m al

process of rail wear. Remove t hese burrs

with a flat file.

S Whenrailtopisuneven,useaflatfiletor e-

store square edges andsides.

Correct GrooveWorn Groove

File Rail Edges

and Sides

Square

Replaceguidebar w henthegroove isworn,

the guide bar is bent or cracked, or when

excess heatingorburringoftherailsoccurs.

Ifreplacement i snecessary ,useonly t heguide

barspecifiedforyoursawintherepai rpartslist

or on the decal located on the chain saw .

SPARK PLUG

The spark plug should be replaced each

year to ensure the engine starts easier and

runs better. Ignition timing isfixed andnon-

adjustable.

1. Loosen 3 screws on cylinder cover.

2. Remove t he cylinder cover.

3. Pull off the spark plug boot.

4. Remove spark plug from cylinder and

discard.

5. Replace with Cham pion RCJ--7Y spark

plug and tighten securely with a 19 mm

socket wrench. Spark plug gap should

be 0,5 mm.

6. Reinstall the spark plug boot.

7. Reinstall the cylinder cover and 3

screws. Tighten securely.

Screws

Spark

Plug Boot

Spark

Plug

Cylinder

Cover

CHAIN SHARPENING

Chain sharpening isa complicated task that

requires special tools. We recommend that

you referchain sharpeningto aprofessional

chain sharpener.

CARBURETOR ADJUSTMENTS

WARNING: Thechainwillbemoving

during most of this procedure. W ear your pro-

tective equipment and observe all safety pre-

cautions. The chain must not move at idle

speed.

The carburetor hasbeen carefully set atthe

factory. Adjustments m ay be necessary if

you notice any of the following conditions:

S Chain moves atidle. S eeIDLE SPEED--T

adjusting procedure.

S Sawwillnotidle.See IDLESPEED--T ad-

justing procedure.

Idle Speed---T

Allow engineto idle. If thechain moves,idle

istoofast. Iftheenginestalls,idleistooslow.

Adjustspeeduntil engineruns withoutchain

movement (idle too f ast) or stalling (idle too

slow). Theidlespeedscrew islocatedinthe

area above theprimer bulb andis labeledT.

S Turnidle speed s crew (T) c lockwise to in-

crease engine speed.

S Turn idle speed screw (T) counterclock-

wise todecrease engine speed.

STORAGE

WARNING:Stopengineandallowto

cool, and secure the unit before storing or

transporting in avehicle. Store unit and fuel

in an area where fuel vapors cannot reach

sparks or open flames fro m water heaters,

electric motors or switches, furnaces, etc.

Storeunitwithallguardsinplace.Positionso

that any sharp object cannot accidentally

causeinjury topassersby .Store theunitout

of reach of children.

S Before storing, drain all fuel from the unit.

Start engineand allowto rununtil itstops.

S Clean theunit befor estoring. Pay p articu-

larattention totheair intake area,keeping

it free of debr is. Use a m ild deter gentand

sponge to clean the plastic surfaces.

S Donotstoretheunitorfuelinaclosedarea

where fuelvapors canrea ch sparks or an

openflamefromhotwaterhea ters,electric

motors or switches, furnaces, etc.

S Store i na dr y areaout ofthereachof chil-

dren.

S Ensurethe machine i s cleanedand that a

complete service is carried out before

long--term storage.

S The guide bar and chain must always be

covered with a scabbard when the m achine

is being transported or in storage in order to

prevent accident contact with the sharp

chain. Even a non--moving chain can cause

serious cuts to yourself or persons you

bump into with an exposed chain.