8

WARNING – DANGER

UNPLUG THE UNIT BEFORE LUBRICATING

OR ADJUSTING THE BLADES.

Maintenance

Service maintenance guide

A. Lubrication

1. A few drops of light No. 10 oil should be placed on the

back edge of each adjusting screw head approximately

after every 4 hours of normal operation.

2. To obtain trouble free trimming, it is necessary to keep the

blades lubricated and clean. The gum that collects and

builds up on the blades can be removed with a 50-50

mixture of kerosene and No. 10 oil. As petroleum products

can shorten the life of some plastics, it is necessary to

remove excess oil-kerosene mixture from the plastic parts.

3. When blades are replaced, or any other time that the

bottom cover plate is removed, the grease level should be

checked for proper amount (approximately 1/2 full in the

area of the gears) and a new gasket should be used to

insure proper seating of the cover plate. Grease should be

added every 25 hours of use. Use EP2 white lithium grease

in the gear housing.

4. Lubricate male spline part of the drive shaft with EP2

White Lithium grease.

B. Storage

1. Store your trimmer in a dry and dust free space, out of the

reach of children.

2. Clean the blades thoroughly and coat them with No. 10 oil

to prevent rust.

3. Perform all required maintenance and service found in this

manual.

4. Use blades cover.

Area Maintenance Before Every 25 Every 50 Every 100 Note

use hours hours hours

Cutting parts Replace if

✔

something is wrong

Gear case Grease

✔

Use EP2 white

Lithium grease

Screws, nuts Tighten, replace

✔✔

Not adjusting

bolts screws

Spline (male) Lubricate

✔

Use EP2 white

Lithium grease

Blades Oiling

✔

Light #10 oil

IMPORTANT: Time intervals shown are maximum. Actual use and your experience will determine the frequency of

required maintenance.

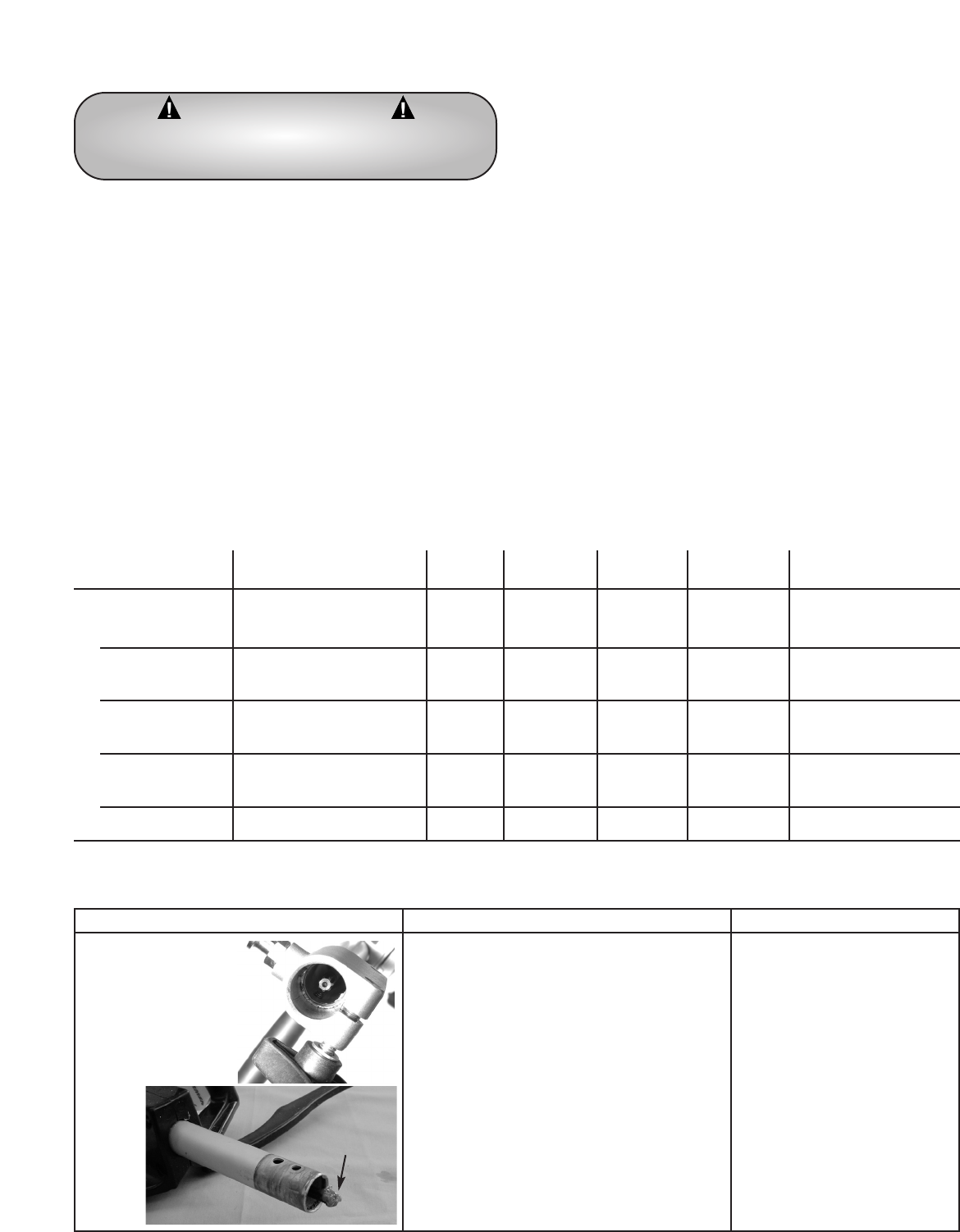

Area Maintenance procedure Frequency

Spline male/female

connection of the

inner drive shaft

Inspect/lubricate

1. Remove the side screw, and loosen

up other three as shown on the

diagram (left).

2. Pull the shaft from the gear housing.

3. Pull and clean internal shaft.

4. Lubricate.

5. Re-install the drive shaft.

6. Do not allow any dirt and dust

on the internal drive shaft

7. Do not allow any dirt and dust

entering into the gear case

20-25 hrs

Lubricate