13

Checking and adjusting the idling speed

The cutting blades should not run when the engine is at idle.

- Idle speed should be set to 3,000 min

-1

(rpm).

- If necessary, adjust the idle screw (the cutting blades must not run when the

engine is on idle).

• The cutting blades run while idling - turn the idle screw counterclockwise to

decrease the idle speed.

• The engine stops while idling - turn the idle screw clockwise to increase the idle

speed.

If the cutting blades still continue to run at idle after the adjustment, consult your

nearest authorized service agent.

• The clutch should engage at 3,750 min

-1

(rpm) or higher revolution.

• Check the functioning of the I-O switch, the lock-off lever and the throttle lever.

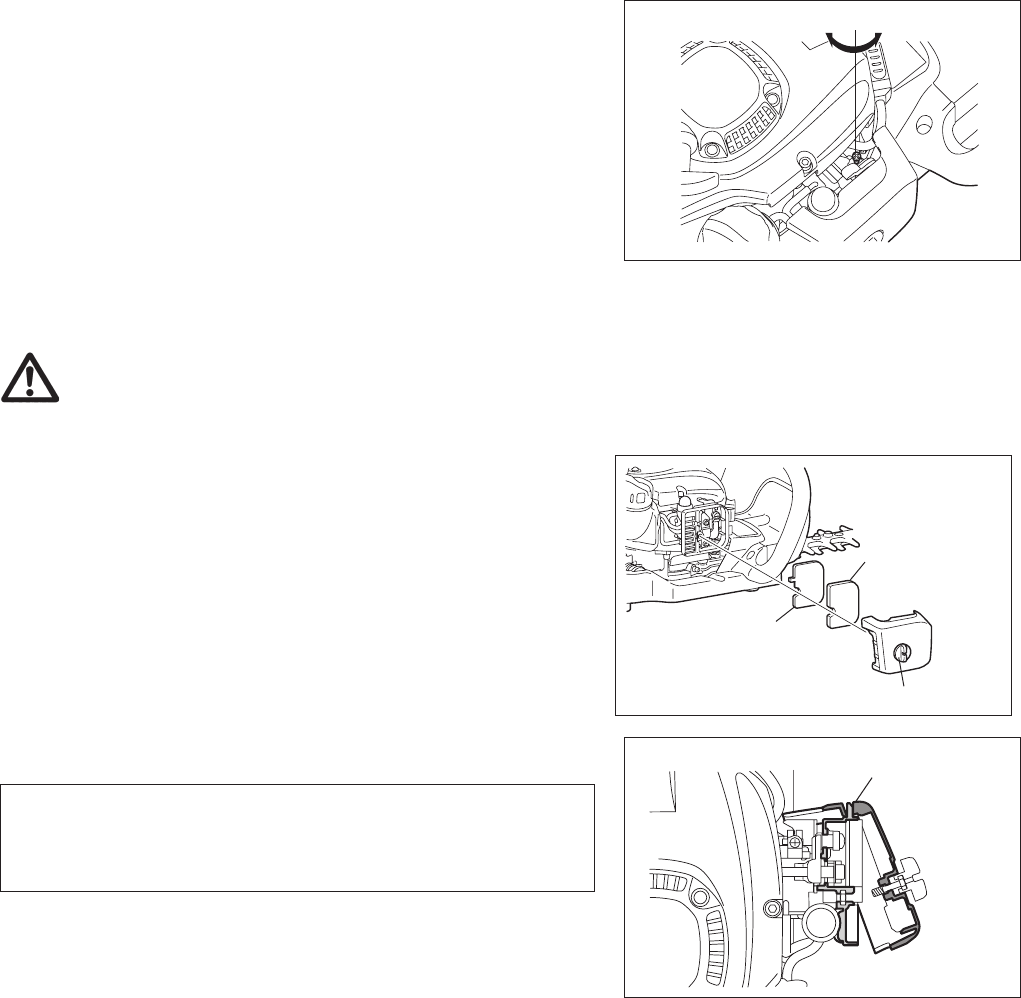

Cleaning the air cleaner

DANGER: Inammables strictly prohibited

Check and clean the air cleaner daily or every 10 operating hours.

- Turn the choke lever to the close side fully, and keep the carburetor free from

dust or dirt.

- Loosen the xing bolt.

- Pull the rear side of the air cleaner cover and move it forward to detach.

- If oil adheres to the element (sponge), squeeze it rmly.

- For heavy contamination:

1) Remove the element (sponge), immerse it in warm water or in water-diluted

neutral detergent, and dry it completely.

2) Clean the element (felt) with gasoline, and dry it completely.

- Before attaching the elements, be sure to dry it completely. Insufcient drying of

the elements may lead to difcult startup.

- Wipe out oil adhering around the air cleaner with waste cloth.

- Immediately after cleaning is nished, attach the cleaner cover and tighten it with

xing bolts. (In remounting, rst place the upper claw.)

Points in handling the air cleaner elements

- Clean the elements several times a day, if excessive dust adheres to it.

- If operation continues with the elements remaining not cleared of oil, oil in

the air cleaner may fall outside, resulting in oil contamination.

Element (Sponge)

Fixing bolt

Element (felt)

Upper claw