37

Cleaning the air lter

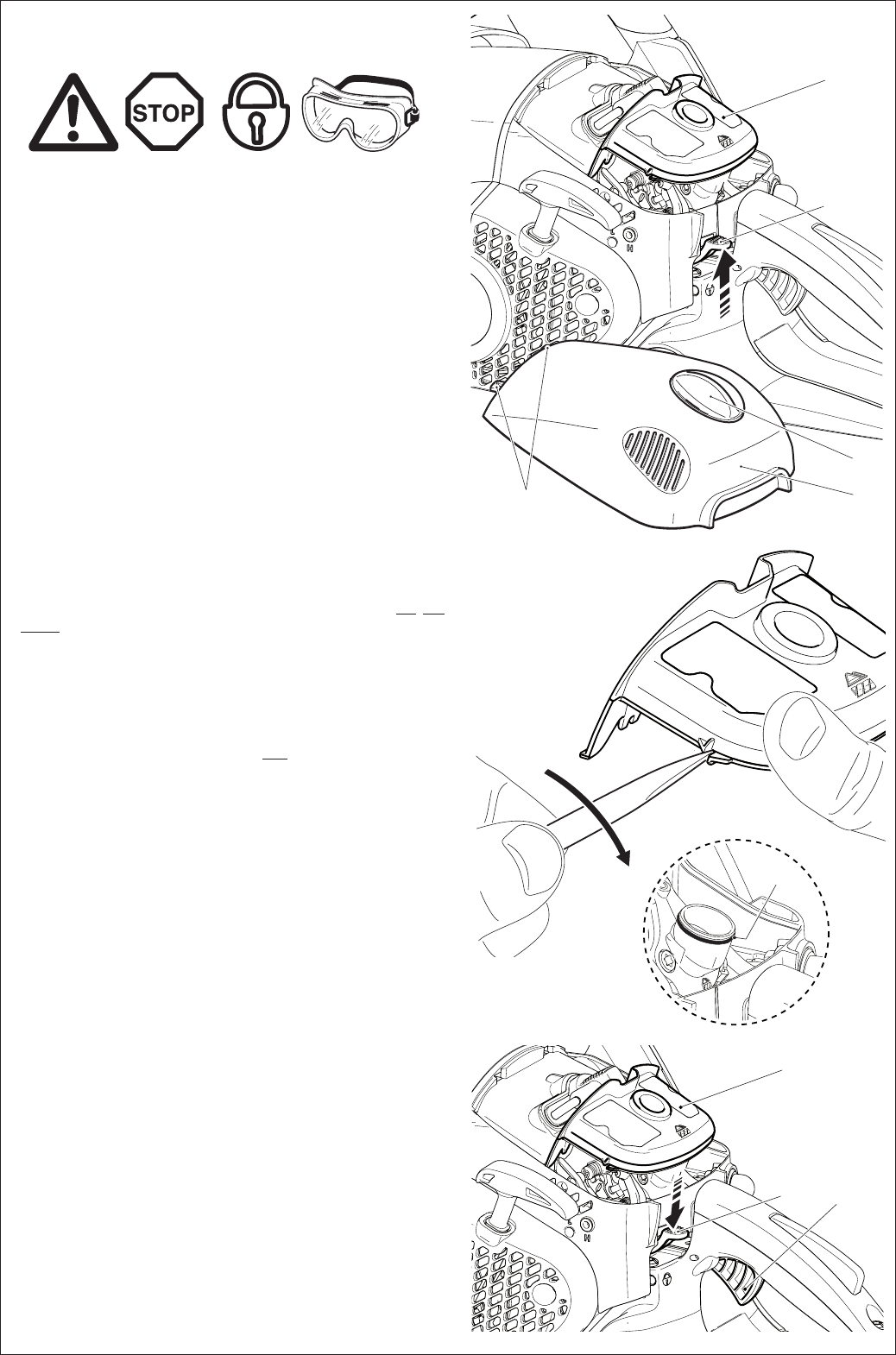

1

2

7

3

4

5

3

4

6

CAUTION: To prevent eye injury, always wear eye protection

when cleaning the lter with compressed air!

Do not use fuel to clean the air lter.

Unscrew the hood lock (1) counter-clockwise and remove the

hood (2).

Push up the combination switch (3) (Choke position) to prevent

dirt particles from falling into the carburetor.

Pull the air lter (4) up and out.

IMPORTANT: Cover the intake opening with a clean cloth to

prevent dirt particles from getting into the carburetor.

Choosing the right lter: The eece lter is for use in dry or

dusty conditions. The nylon lter (available as accessory) is for

use in damp conditions.

Pry apart the top and bottom of the air lter as shown in Fig-

ure.

Cleaning the eece lter: Carefully tap out dust or carefully

blow out dust from the inside with compressed air. Do not

brush the eece, as this will force dirt particles into the fabric.

If the lter is very dirty, it can be washed in lukewarm water

with regular dishwashing detergent. Note that the eece lter

does not need to be cleaned until there is a noticeable loss of

power. If cleaning the lter does not bring an improvement in

performance, it is time to replace it.

Cleaning the nylon lter: Use a soft brush or blow out dirt

from the inside with compressed air. If the lter is very dirty, it

can be washed in lukewarm water with regular dishwashing

detergent. Clean frequently (several times a day) when working

in very dusty or dirty conditions. Full engine power is possible

only with a clean air lter!

Let the air lter dry completely.

Put the top and bottom sections back together.

Before assembling the air lter, check the choke ap for any dirt

particles. If there are any, remove them with a brush.

Clean the area around the O-ring (5) at the induction opening.

If the O-ring is damaged, replace it!

CAUTION: If the air lter becomes damaged, replace imme-

diately! Pieces of cloth or large dirt particles can destroy

the engine!

Insert an air lter (4).

Push down the combination switch (3) and press the throttle

(6) all the way down one time in order to deactivate the throt-

tle lock.

Put the hood (2) back on, rst guiding the two holders (7) into

their slots.

Screw the hood lock (1) back on tightly clockwise.