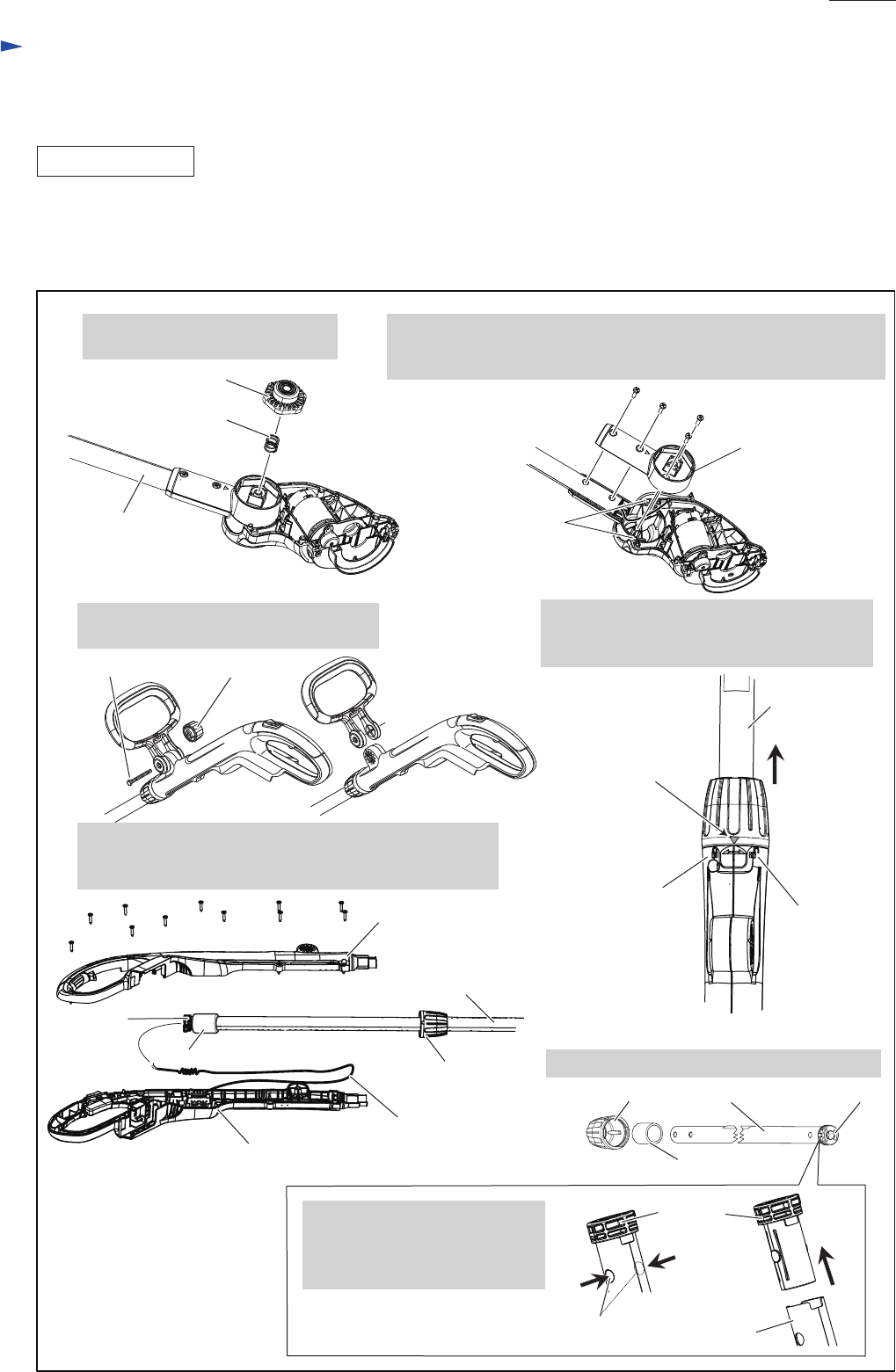

[3] DISASSEMBLY/ASSEMBLY

[3] -3. Pipe section

DISASSEMBLING

Lock off button B

1. Remove Lock off button B and

Compression spring 12.

3. Remove M6 Nut and M6x60 Hex bolt.

And remove Front grip.

5. Remove Handle (R) from Handle (L) by unscrewing

eleven 4x18 Tapping screws.

Pull out Power supply cord unit from Pipe 25 complete.

2. Remove Pipe holder (R) by unscrewing four 4x18 Tapping screws

and disconnect Lead wires (black, white) from DC motor.

Note: Be careful not to lose Rubber pin 6.

7. While pressing the projections

on the both sides of Pipe 25

complete, pull off Pipe cap

from Pipe 25 complete.

Compression spring 12

(1) Remove Spool set and Safety cover as drawn in Fig. 2.

(2) Separate Motor housing (R) from Motor housing (L) as drawn in Fig. 3.

(3) Disassemble Pipe 25 complete as drawn in Fig. 6.

Fig. 6

Pipe holder (R)

Rubber pin 6

Symbol of

“Lock”

Pipe 25

Symbol of

“Unlock”

4. While aligning the indicator (triangle) on

Lock sleeve to the just center of “Unlock”

and “Lock”, pull off it toward Pipe 25 side.

Pipe 25

Handle (R) complete

Pipe 25 complete

Pipe 25 complete

Rubber sleeve 25

Handle (L) complete

Indicator (triangle)

on Lock sleeve

Lock sleeve

Pipe 25

complete

Pipe cap

Pipe cap

Pipe cap

Projections of

Pipe cap

Lock sleeve

Rubber sleeve 25

Power supply cord unit

6. Remove Lock sleeve and Rubber sleeve 25.

M6 NutM6x60 Hex bolt

Repair

P 6/ 12